Masu haɗa tashar tashar motaa fagen na'ura mai ba da hanya tsakanin hanyoyin sadarwa wani muhimmin bangare ne na filin, amma kuma kai tsaye tantance siginar mai haɗawa da watsa wutar lantarki mai mahimmancin nodes. Tare da saurin bunkasuwar masana'antar kera motoci ta kasar Sin, ci gaba da inganta fannin na'urorin kera motoci har ila yau, yana sa kaimi ga mai hada motoci zuwa wani ingantaccen ci gaba mai inganci da aminci.

Ta hanyar yin bitar matsalolin da suka gabata a cikin amfani da tashoshi masu haɗawa, mun gano cewa waɗannan abubuwan zasu shafi ikon watsa tashoshi: kayan aiki, tsarin ƙira, ingancin saman, da crimping.

Kayan aikin tashar

Yin la'akari da ayyuka da tattalin arziki, masana'antun haɗin gida yawanci suna amfani da abubuwa biyu: tagulla da tagulla. Brass yawanci yana dacewa da kyau, amma mafi sassauƙan tagulla. Ganin filogi da tashoshi na soket a cikin tsarin bambance-bambancen, gabaɗaya suna ba da fifiko ga amfani da tashoshi maimakon tagulla mai ɗaukar nauyi. Wuraren soket ɗin da kansu yawanci suna da ƙira mai sassauƙa, la'akari da buƙatun ɗabi'a, kuma galibi suna zaɓar kayan tagulla don tabbatar da amincin shrapnel ɗin tasha.

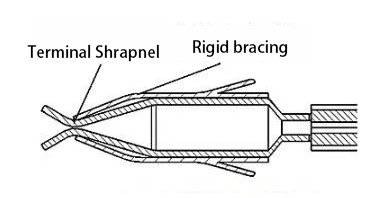

Domin in mun gwada da stringent conductivity buƙatun na soket tashoshi, saboda conductivity na tagulla abu kasa iya biyan bukatun, da general yi shi ne ya zabi tagulla soket m kayan, la'akari da lahani na tagulla abu da kanta ne m m. za a rage elasticity. A cikin tsarin ƙara ƙaƙƙarfan tsarin tallafi don ƙara elasticity na tashoshi. Kamar yadda aka nuna a hoto (1).

Hoto 1 Tsarin tsari na tashar soket tare da tsayayyen tallafi

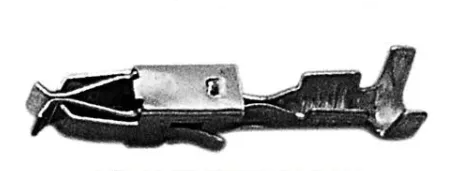

A cikin bayanin da ke sama na tsarin tashoshi tare da m goyon baya a cikin Hoto (2), tsarin tallafi mai tsauri yana inganta ingantaccen matsin lamba na shimfidar laminating, don haka inganta ingantaccen amincin samfurin.

Hoto 2 Hoton tashar soket tare da tsayayyen goyan baya

Tsarin tsari

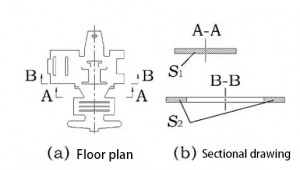

Ainihin, tsarin ƙirar shine ainihin buɗaɗɗen tushe don rage farashin albarkatun ƙasa, tare da kiyaye watsa wutar lantarki na tashoshi. Saboda haka, masu haɗin haɗin haɗin gwiwa sun fi dacewa da tasirin watsa wutar lantarki a matsayin wani ɓangare na tsarin su na "bottleneck", wanda ke nufin tashoshi a cikin shimfidar wuri na mafi ƙanƙanta giciye na tsarin. Kamar yadda aka nuna a cikin hoto (3), tsarin yana tasiri kai tsaye ƙarfin ɗaukar hoto na tashar.

Hoto na 3 Tsarin tsari na fadada tasha

Hoto na 3b yana nuna cewa yanki na yanki na S1 ya fi S2 girma, don haka ɓangaren giciye na BB yana cikin yanayin kwalba. Wannan yana nuna cewa, a cikin tsarin ƙira, sashin giciye dole ne ya cika buƙatun gudanarwa na tashar.

A saman plating

A mafi yawan masu haɗawa, tin plating hanya ce ta gama gari. Abubuwan da ke tattare da plating ɗin gwangwani sun haɗa da abubuwa biyu masu zuwa: na farko, platin tin zai haifar da raguwar solderability da haɓaka juriya, wanda galibi ya samo asali ne daga plating da ƙarfe na tsaka-tsaki tsakanin ƙarfe. Abu na biyu, kayan tuntuɓar da aka ɗora yana da mafi girman jujjuyawar ƙasa idan aka kwatanta da ƙarfe mai ɗorewa, wanda ke haifar da haɓaka ƙarfin shigar da mai haɗawa, musamman a cikin masu haɗa waya da yawa.

Saboda haka, don plating na multiwire haši, sabon plating matakai ana amfani da duk inda zai yiwu don tabbatar da canja wurin haɗi yayin da rage saka halin yanzu. Misali, platin zinari shine tsari mai kyau na plating.

Daga mahangar micro-physical, duk wani fili mai santsi yana da ƙasƙanci da ƙasa mara daidaituwa, don haka tuntuɓar tashoshi lamba ce maimakon tuntuɓar ƙasa. Bugu da ƙari, yawancin saman ƙarfe suna rufe da oxide maras amfani da sauran nau'ikan yadudduka na fim, don haka kawai a cikin ma'anar ma'anar wuraren hulɗar lantarki - wanda ake kira "aibobi masu aiki - yana yiwuwa a sami lambar lantarki.

Kamar yadda mafi yawan lambar sadarwa ta hanyar sadarwar fim ne, lokacin da na yanzu ya kasance ta hanyar sassan sadarwa guda biyu, zai mayar da hankali kan waɗancan ƙananan wuraren gudanarwa.

Sabili da haka, a cikin kusancin wuraren da ake gudanarwa na layi na yanzu za a yi kwangilar, wanda zai haifar da karuwa a cikin tsawon hanyar da ke gudana a halin yanzu, kuma an rage tasirin tasiri mai tasiri. Wannan juriya na gida ana kiranta "juriya na raguwa" kuma yana haɓaka ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun tashoshi.

A halin yanzu, akwai ma'auni guda biyu don kimanta ingancin plating: na farko, kimanta kauri na plating. Wannan hanya tana kimanta ingancin suturar ta hanyar auna kauri na sutura. Na biyu, ana kimanta ingancin plating ta amfani da gwajin feshin gishiri mai dacewa.

Ingantacciyar matsin lamba na shrapnel tasha

Matsakaicin tabbataccen matsi mai haɗawa shine muhimmin nuni na aikin mai haɗawa, yana tasiri kai tsaye ƙarfin shigar da tasha da kaddarorin lantarki. Yana nufin madaidaicin filogi mai haɗawa da madaidaicin madaidaicin wurin tuntuɓar lamba.

A cikin amfani da tashoshi, matsalar da aka fi sani da ita ita ce shigar da ƙarfin da ke tsakanin tashar da kuma kula da tashar ba ta da kyau. Wannan shi ne saboda rashin kwanciyar hankali tabbatacce matsa lamba a kan m shrapnel, wanda take kaiwa zuwa wani karuwa a cikin juriya na m lamba surface. Wannan yana haifar da haɓakar haɓakar zafin jiki na tashoshi, yana haifar da ƙona mai haɗawa da asarar aiki, ko ma a cikin matsanancin yanayi, ƙonewa.

Dangane da QC/T417 [1], juriya na lamba shine juriya tsakanin wuraren tuntuɓar mai haɗawa kuma ya haɗa da abubuwa masu zuwa: juriya na ciki na tashoshi, juriya da ta haifar da crimping na masu gudanarwa, juriya na waya. a ma'anar tunani, da kuma juriya na shrapnel na filogi da tashoshi a cikin lamba (Fig. 4).

Abubuwan da ke ƙarewa galibi suna shafar juriya na ciki, ingancin samfur ɗin yana shafar juriya da aka haifar ta hanyar crimp ɗin madugu, tashar filogi da shrapnel na soket a cikin hulɗa tare da juriya da ke haifar da halayen gudanarwa na tashar, da hauhawar zazzabi na darajar tasiri mai mahimmanci. Saboda haka, a cikin zane na mahimman la'akari.

Hoto4 Tsarin tsari na juriyar lamba

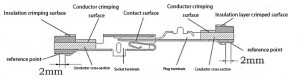

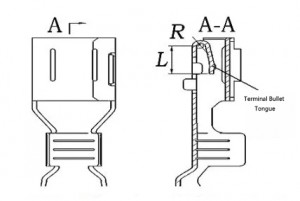

Matsi mai kyau akan tashar tasha ya dogara da elasticity na ƙarshen harshen harsashi. Radius mai lankwasa R da tsayin cantilever L na harshe suna da tasiri kai tsaye akan wannan darajar kuma dole ne a yi la'akari da su yayin tsarin ƙira. Ana nuna tsarin shrapnel tasha a hoto na 5.

Hoto 5 Tsarin tsari na tsarin shrapnel na ƙarshe

Ciwon wutsiya

Ingancin watsa tashar tashoshi yana tasiri kai tsaye ta hanyar crimping ingancin tashar. Tsawon haɗin gwiwa da tsayin ƙugiya suna da tasiri mai mahimmanci akan ƙimar ƙima. Ƙunƙarar ƙanƙara yana da ingantacciyar ƙarfin injina da kayan lantarki, don haka ya kamata a sarrafa girman sashin ƙwanƙwasa. Diamita na waya abu ne mai mahimmanci wanda ke tasiri tasirin crimping tsakanin tashar da waya.

Bugu da ƙari, waya kanta ma ya cancanci yin nazari, saboda kayan gida da na waje suna da nasu halaye na musamman. A cikin ainihin samarwa, ya kamata a lura da ka'idodin masu zuwa: ya kamata a daidaita diamita na waya tare da ƙarshen ƙarshen, tsawon sashin kai ya kamata ya zama matsakaici, da kuma crimping mold mai dacewa, crimping bayan gwajin Rattori.

Bincika hanyoyin crimping na tasha gami da duba bayanan crimping na tasha da ƙarfin cirewa. Ta hanyar duba bayanan martaba, zaku iya tantance sakamakon da aka yanke don tabbatar da cewa babu lahani kamar bacewar wayoyi na jan karfe ko ƙasa. Bugu da ƙari, ƙarfin cirewa yana kimanta amincin kullun.

Lokacin aikawa: Yuli-18-2024