Automotive davhlau ya nyob twg connectorsnyob rau hauv lub tshav pob ntawm automotive wiring harness yog ib qho tseem ceeb ntawm lub tshav pob, tab sis kuj ncaj qha txiav txim lub connector teeb liab thiab lub hwj chim kis tau tus mob ntawm tseem ceeb nodes. Nrog rau txoj kev loj hlob sai ntawm Tuam Tshoj txoj kev lag luam automotive, kev txhim kho tas mus li ntawm thaj chaw ntawm cov khoom siv tsheb kuj txhawb nqa lub tsheb txuas mus rau kev txhim kho ntau dua thiab txhim khu kev qha.

Los ntawm kev tshuaj xyuas cov teeb meem yav dhau los hauv kev siv cov terminals txuas, peb pom tias cov hauv qab no yuav cuam tshuam rau lub peev xwm xa cov terminals: cov ntaub ntawv, cov qauv tsim, qhov zoo, thiab crimping.

Cov khoom siv ntawm lub davhlau ya nyob twg

Nrog rau kev ua haujlwm thiab kev lag luam, kev lag luam txuas hauv tsev feem ntau siv ob yam khoom: tooj dag thiab tooj liab. Brass yog feem ntau conducive rau zoo, tab sis ntau saj zawg zog bronze. Muab cov ntsaws ntsaws thiab lub qhov (socket) terminals nyob rau hauv cov qauv ntawm qhov sib txawv, feem ntau yog qhov tseem ceeb ntawm kev siv cov plug terminals es tsis yog cov tooj dag ntau dua. Lub qhov (socket) terminals lawv tus kheej feem ntau muaj cov qauv siv tau yooj yim, coj mus rau hauv tus account qhov yuav tsum tau ua, thiab feem ntau xaiv cov khoom siv tooj liab kom ntseeg tau qhov kev ntseeg siab ntawm lub davhlau ya nyob twg shrapnel.

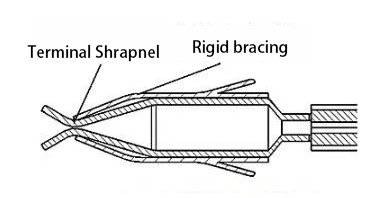

Rau cov kev cai nruj me ntsis ntawm lub qhov (socket) terminals, vim tias cov khoom siv tooj liab tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua, kev coj ua yog xaiv cov khoom siv tooj dag lub qhov (socket) davhlau ya nyob twg, suav nrog qhov tsis xws ntawm cov khoom siv tooj dag nws tus kheej tsis hloov pauv, lub elasticity yuav raug txo. Nyob rau hauv cov qauv nce cov kev txhawb nqa nruj kom nce elasticity ntawm cov terminals. Raws li pom hauv daim duab (1).

Daim duab 1 Daim duab kos duab ntawm lub qhov (socket) davhlau ya nyob twg nrog kev txhawb nqa nruj

Nyob rau hauv cov lus piav qhia saum toj no ntawm cov qauv davhlau ya nyob twg nrog kev txhawb nqa nruj hauv daim duab (2), cov qauv kev txhawb nqa nruj txhim kho lub siab zoo ntawm cov txheej txheem laminated nto, yog li txhim kho cov kev ntseeg tau ntawm cov khoom.

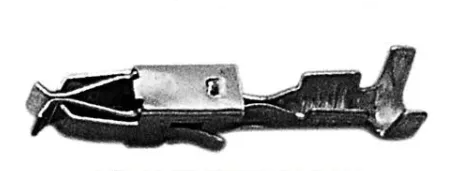

Daim duab 2 Daim duab ntawm lub qhov (socket) terminal nrog kev txhawb nqa nruj

Tus qauv tsim

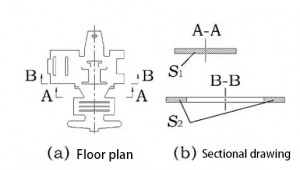

Hauv cov ntsiab lus, cov qauv ntawm cov qauv tsim yog qhov tseem ceeb qhib qhov chaw kom txo qis tus nqi ntawm cov khoom siv raw, thaum tswj lub zog xa hluav taws xob ntawm cov terminals. Yog li ntawd, lub connector terminals yog feem ntau yooj yim rau kev cuam tshuam ntawm lub hwj chim kis tau tus mob raws li ib feem ntawm lawv "bottleneck" qauv, uas yog hais txog cov terminals nyob rau hauv lub conductive nto ntawm qhov tsawg tshaj plaws cross-section ntawm tus qauv. Raws li pom hauv daim duab (3), cov qauv ncaj qha cuam tshuam rau lub peev xwm nqa tam sim no ntawm lub davhlau ya nyob twg.

Daim duab 3 Schematic daim duab ntawm lub davhlau ya nyob twg expansion

Daim duab 3b qhia tau hais tias qhov chaw hla ntu ntawm S1 loj dua S2, yog li ntu ntu ntawm BB yog nyob rau hauv lub xeev fwj. Qhov no qhia tau hais tias, nyob rau hauv tus txheej txheem tsim, tus ntoo khaub lig-section yuav tsum tau raws li cov kev xav tau ntawm lub davhlau ya nyob twg.

Qhov saum npoo plating

Nyob rau hauv feem ntau cov connectors, tin plating yog ib qho kev plating feem ntau. Qhov tsis zoo ntawm tin plating muaj xws li ob qho hauv qab no: ua ntej ntawm tag nrho cov, tin plating yuav ua rau kom txo cov solderability thiab nce kev tiv thaiv, uas feem ntau yog los ntawm plating thiab hlau intermetallic tiv thaiv ntawm cov hlau. Qhov thib ob, cov khoom siv sib txuas plated muaj qhov sib txhuam ntau dua piv rau cov hlau plated, uas ua rau muaj kev nce ntxiv ntawm cov khoom sib txuas, tshwj xeeb tshaj yog nyob rau hauv ntau cov hlau txuas.

Yog li ntawd, rau plating ntawm multiwire connectors, cov txheej txheem tshiab plating yog siv nyob qhov twg los tau los xyuas kom meej kev twb kev txuas hloov lwm lub tsev thaum txo qhov ntxig tam sim no. Piv txwv li, kub plating yog txheej txheem plating zoo.

Los ntawm qhov pom ntawm micro-physical, txhua qhov chaw du muaj qhov ntxhib thiab tsis sib xws, yog li kev sib cuag ntawm cov terminals yog qhov chaw sib cuag es tsis yog qhov sib cuag. Tsis tas li ntawd, cov hlau feem ntau yog them los ntawm cov tsis muaj hluav taws xob oxide thiab lwm yam txheej txheej zaj duab xis, yog li tsuas yog nyob rau hauv qhov tseeb ntawm cov hluav taws xob tiv tauj cov ntsiab lus - hu ua "conductive spots - nws puas tuaj yeem muaj hluav taws xob sib cuag.

Raws li feem ntau ntawm kev sib cuag yog los ntawm kev sib cuag zaj duab xis, thaum tam sim no yog los ntawm ob qhov chaw sib cuag ntawm lub interface, nws yuav tsom mus rau cov me me conductive me ntsis.

Yog li ntawd, nyob rau hauv ib ncig ntawm lub conductive me ntsis ntawm cov kab tam sim no yuav tau cog lus, uas ua rau kom ib tug nce nyob rau hauv qhov ntev ntawm txoj kev ntawm lub tam sim no ntws, thiab qhov zoo conductive cheeb tsam yog txo. Qhov kev tiv thaiv hauv cheeb tsam no yog hu ua "shrinkage resistance" thiab txhim kho qhov chaw tiav thiab kev sib kis ntawm cov terminals.

Tam sim no, muaj ob txoj hauv kev los ntsuas qhov zoo ntawm plating: ua ntej, ntsuas qhov tuab ntawm plating. Txoj kev no ntsuas qhov zoo ntawm txheej los ntawm kev ntsuas lub thickness ntawm txheej. Qhov thib ob, qhov zoo ntawm cov plating yog ntsuas los ntawm kev ntsuas tshuaj ntsev kom tsim nyog.

Qhov zoo siab ntawm lub davhlau ya nyob twg shrapnel

Connector davhlau ya nyob twg zoo siab yog ib qho tseem ceeb qhia ntawm connector kev ua tau zoo, ncaj qha cuam tshuam rau lub davhlau ya nyob twg insertion quab yuam thiab hluav taws xob khoom. Nws yog hais txog lub connector plug davhlau ya nyob twg thiab lub qhov (socket) davhlau ya nyob twg tiv tauj nto perpendicular mus rau qhov kev sib cuag nto quab yuam.

Hauv kev siv cov terminals, qhov teeb meem tshwm sim feem ntau yog lub zog ntxig ntawm lub davhlau ya nyob twg thiab lub davhlau ya nyob twg tswj tsis ruaj khov. Qhov no yog vim qhov tsis ruaj tsis khov zoo siab ntawm lub davhlau ya nyob twg shrapnel, uas ua rau muaj kev nce ntxiv hauv qhov kev tiv thaiv ntawm qhov chaw sib tiv tauj. Qhov no ua rau kom qhov kub thiab txias nce ntawm cov terminals, uas ua rau lub connector burnout thiab poob ntawm conductivity, los yog txawm nyob rau hauv heev mob, burnout.

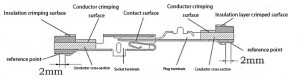

Raws li QC / T417 [1], kev tiv thaiv kev tiv thaiv yog qhov kev tiv thaiv ntawm cov ntsiab lus sib txuas ntawm cov khoom sib txuas thiab suav nrog cov hauv qab no: qhov kev tiv thaiv ntawm cov terminals, qhov kev tawm tsam uas tshwm sim los ntawm crimping ntawm cov conductors, kev tiv thaiv ntawm cov hlau. ntawm qhov taw tes ntawm kev siv, thiab kev tiv thaiv ntawm cov shrapnel ntawm lub ntsaws thiab lub qhov (socket) terminals nyob rau hauv kev sib cuag (Fig. 4).

Cov khoom siv davhlau ya nyob twg feem ntau cuam tshuam rau qhov kev ua haujlwm ntawm lub cev, qhov zoo ntawm cov khoom cuam tshuam rau kev ua haujlwm ntawm tus neeg xyuas pib crimp, ntsaws lub davhlau ya nyob twg thiab lub qhov (socket) davhlau ya nyob twg shrapnel nyob rau hauv kev sib cuag nrog cov kuj generated los ntawm cov conductive yam ntxwv ntawm lub davhlau ya nyob twg, thiab qhov kub thiab txias ntawm lub davhlau ya nyob twg. tus nqi ntawm qhov cuam tshuam tseem ceeb. Yog li ntawd, nyob rau hauv kev tsim ntawm cov ntsiab lus tseem ceeb.

Daim duab4 Schematic daim duab ntawm kev tiv thaiv tiv thaiv

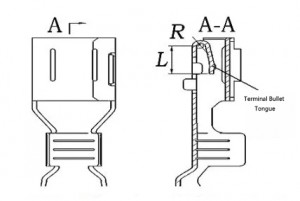

Qhov zoo siab ntawm lub davhlau ya nyob twg nyob ntawm qhov elasticity ntawm qhov kawg ntawm tus nplaig mos txwv. Lub vojvoog dabtsi yog khoov R thiab lub cantilever ntev L ntawm tus nplaig muaj kev cuam tshuam ncaj qha rau tus nqi no thiab yuav tsum raug coj mus rau hauv tus account thaum lub sijhawm tsim qauv. Tus qauv ntawm lub davhlau ya nyob twg shrapnel yog qhia hauv daim duab 5.

Daim duab 5 Schematic daim duab ntawm lub davhlau ya nyob twg shrapnel qauv

Tail crimping

Kev sib kis zoo ntawm lub davhlau ya nyob twg yog ncaj qha cuam tshuam los ntawm crimping zoo ntawm lub davhlau ya nyob twg. Qhov kev sib koom ua ke ntev thiab qhov siab ntawm crimp muaj qhov cuam tshuam tseem ceeb ntawm crimp zoo. Lub crimp nruj muaj zog dua lub zog thiab cov khoom hluav taws xob, yog li ntawd qhov ntev ntawm Crimp tshooj yuav tsum yog kev tswj hwm nruj me ntsis. Txoj kab uas hla ntawm cov hlau yog ib qho tseem ceeb uas cuam tshuam cov nyhuv crimping ntawm lub davhlau ya nyob twg thiab cov hlau.

Tsis tas li ntawd, cov hlau nws tus kheej kuj tsim nyog kawm, vim tias cov khoom siv hauv tsev thiab txawv teb chaws muaj lawv tus kheej tshwj xeeb. Hauv kev tsim khoom tiag tiag, cov ntsiab lus hauv qab no yuav tsum tau ua raws: txoj kab uas hla ntawm lub xaim yuav tsum tau sib phim nrog qhov kawg ntawm lub davhlau ya nyob twg, qhov ntev ntawm lub taub hau yuav tsum yog nruab nrab, thiab qhov tsim nyog crimping pwm, crimping tom qab ntsuas Rattori.

Txheeb xyuas cov txheej txheem davhlau ya nyob twg crimping nrog rau kev kuaj xyuas lub davhlau ya nyob twg crimping profile thiab rub tawm quab yuam. Los ntawm kev txheeb xyuas qhov profile, koj tuaj yeem pom cov txiaj ntsig ntawm crimping los xyuas kom meej tias tsis muaj qhov tsis xws luag xws li cov hlau tsis muaj tooj liab lossis hauv qab. Tsis tas li ntawd, lub zog rub tawm ntsuas qhov kev ntseeg tau ntawm cov crimp.

Post lub sij hawm: Lub Xya hli ntuj-18-2024