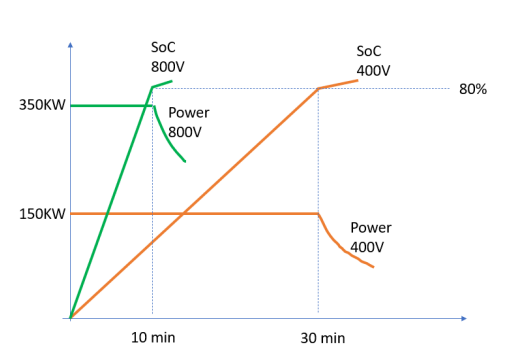

In the rapidly evolving landscape of electric vehicles (EVs), charging speed and efficiency have become make-or-break factors for consumer adoption. Traditional 400V systems have long been a bottleneck—plagued by slow charging times and frequent cable overheating, which hinder user experience and limit EV usability. Enter 800V high-voltage connectors: a transformative solution that addresses these pain points head-on. Take the Porsche Taycan, for example—when paired with a 350kW charging station, 800V connectors slash its charging time from 35 minutes to just 15 minutes, redefining what drivers can expect from fast charging.

The Technical Edge: 800V vs. 400V Systems

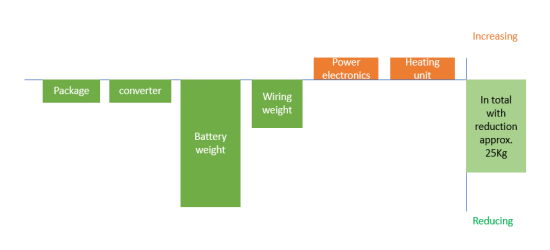

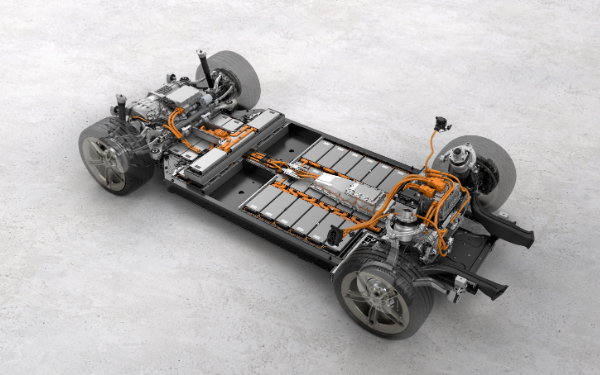

The superiority of 800V systems over legacy 400V setups is clear when examining key performance metrics. In terms of charging power, 400V systems max out at around 150kW, while 800V systems push past 350kW—delivering a 133% boost in power delivery. This leap in power doesn’t come with a trade-off in efficiency, either: 800V systems operate at 175A, a 41.7% reduction from the 300A required by 400V setups. Lower current translates to lighter cabling, too—800V cables weigh 4.2kg per kilometer, compared to 8kg/km for 400V alternatives, cutting weight by 47.5% and improving handling for both charging stations and in-vehicle installations.

Core Innovations Driving 800V Performance

Amphenol and TE Connectivity lead the charge in 800V connector technology, with breakthroughs that optimize reliability and efficiency. Amphenol’s RADSOK® technology stands out: its hyperbolic grid design, formed by stamping and twisting flat conductive alloy, creates a high-density contact area with mating pins. Unlike traditional spring-based contact systems, RADSOK® leverages the tensile strength of its alloy grid to deliver strong normal force for conductivity—reducing contact resistance by 60% compared to conventional designs. This translates to minimal voltage drop, lower heat generation, and easier insertion, critical for high-power charging scenarios.

TE Connectivity complements this with its liquid-cooled solutions, which manage the thermal demands of 350kW+ charging. By integrating cooling channels directly into the connector, TE’s design prevents overheating even during prolonged fast-charging sessions, ensuring consistent performance and extending component lifespan.

Safety and Reliability: Certified for Confidence

800V connectors aren’t just about speed—they’re built to meet the strictest safety standards. Leading solutions carry UL 1977 certification, a benchmark for high-voltage electrical safety that validates insulation integrity, current-carrying capacity, and resistance to environmental stress. Many also comply with ISO 26262, the global standard for automotive functional safety, which covers every stage of development—from design to testing—to minimize risk of failures in critical EV systems.

Real-world testing reinforces this reliability. For instance, Land Rover’s extreme-environment trials showed 800V connectors maintaining 12-minute fast-charging (from 20% to 80% battery) across a temperature range of -24°C to 52°C—proving their ability to perform in harsh climates, from cold northern winters to hot desert summers.

Compatibility and Industry Backing

To drive widespread adoption, 800V connectors support multiple charging protocols, including CCS2, CHAdeMO, and NACS. This cross-compatibility ensures they work with existing and future charging infrastructure, eliminating barriers for EV manufacturers and consumers alike.

Industry leaders further validate the technology. TE Connectivity, for example, is the exclusive connector supplier for Tesla’s Cybertruck—providing high-voltage solutions tailored to the vehicle’s 800V architecture. Amphenol’s 800V connectors, meanwhile, are integrated into popular models like the Lucid Air and Xiaopeng G9, cementing their role as a go-to choice for premium and mainstream EV brands.

The Road Ahead: From 800V to 900V

The evolution of high-voltage connectors shows no signs of slowing down. From 2023 to 2024, 400V systems remained dominant, with setups like Tesla’s V3 Supercharger delivering 250kW. But 2025 marks the dawn of mass 800V adoption, with Porsche, Xiaopeng, and Hyundai leading the charge in production models. Looking ahead to 2026, manufacturers are already prepping 900V systems, leveraging silicon carbide (SiC) components to push power limits further and reduce energy loss—setting the stage for even faster, more efficient EV charging.

For EVs to truly replace internal combustion engines, fast charging must be as convenient as refueling a gas car. 800V high-voltage connectors aren’t just a technical upgrade—they’re the key to unlocking that convenience, making EVs a practical choice for millions more drivers worldwide.

Post time: Aug-29-2025