What is the reason for the oxidation and blackening of terminals?

The process of using the terminal companies often leads to the development of various forms of problems, such as for us can be common oxidation black, if a terminal oxidation black outside there will be a layer of things like soot, that is oxidized, and the formation of black substances, to use sandpaper or file to grind off.

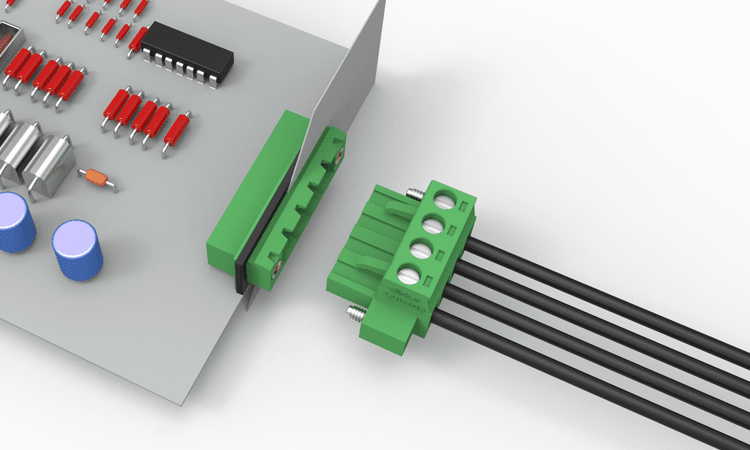

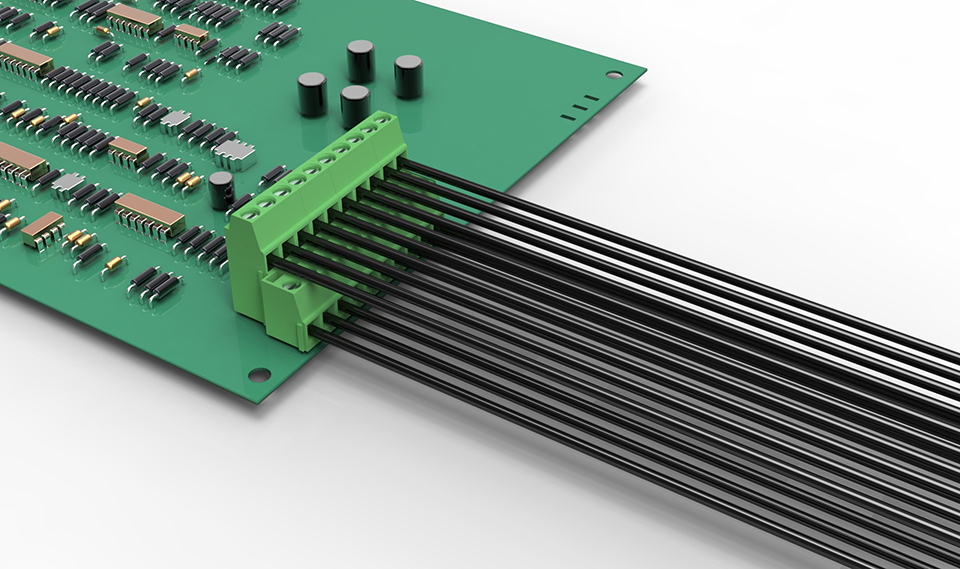

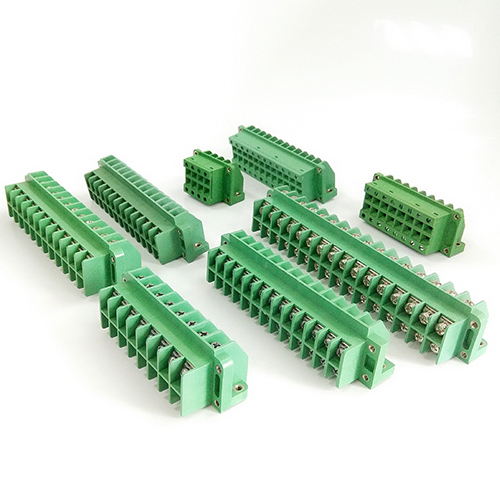

As we all know, the terminals with an increasing degree of industrial automation and industrial control requirements are more and more stringent, and the amount of terminals gradually rises. With the development of the electronics industry, the use of terminals more and more, and more and more types. Terminals to facilitate the connection of wires and applications, it is a section of the seal in the insulating plastic surface of the gold, both ends have holes that can be inserted into the wire, and there are screws for fastening or loosening, such as two wires, sometimes need to be connected, sometimes need to be disconnected, this time you can use the terminals to connect them up and can be disconnected at any time, without having to weld them up or twisted together, it’s very convenient and quick.

However, sometimes there may be this kind of terminal loosening caused by the social contact resistance being too large, thus generating overheating; terminals are not loose, but due to the circuit due to some unknown environmental reasons and overcurrent heating, such as the provision of power supply system voltage is too high, or the load short-circuited, which will also cause the terminal oxidation and blackening. Therefore, the causes of the oxidation and blackening problems of the terminals include the following two points.

1.the voltage is too high. Can be checked from the source, the transformer secondary voltage voltage in the distribution box – the voltage of each power equipment. Sockets can also have assembly fastening and locking fastening. Assembly fastening can play a more solid fixed to the PCB board, locking fastening can be installed after the completion of locking the mother and socket.

A variety of socket designs are available to match different female insertion methods, such as horizontal, vertical, or angled to the PCB. Both metric and standard wire gauges are available.

2. ground fault. You can also check from the transformer there, and then to the distribution box grounding. The grounding should be grounded, while the normal phase wires should be excluded from ground faults. Can be powered off with an insulated meter or shaking table to measure, and segment measurements, try to only segment measurements of cables, wires, circuit breakers, switches, and other power supply and distribution lines, it is really difficult to segment the case, it is pulling out the weak equipment, sensing equipment, fuses.

The key to grounding is grounding resistance should be low, while the contact area should be large. The former can ensure that the grounding point has a potential close to the earth’s potential as low as possible zero potential, which can prevent you think of thunder, or lightning from the grounding line back string to go, run into the possibility of a power supply circuit.

The latter can ensure that there is enough capacity to provide a fault current channel, including lightning or short-circuit faults and so on. Because the actual construction process has been based on the theory of contemporary technology and technological changes and changes, this grounding method is feasible, good or bad, but also to see how the new standard specification.

Terminal contact bad harm

Terminals in the installation process, if there is a bad connection, it will affect the normal use of people, and it is easy to oxidize black.

The correct installation and use of terminals can ensure that the electrical engineering to avoid the occurrence of wiring errors, therefore, the installation of terminals is very important. If there is a lack of appropriate technical means in the construction process, the proper performance of the terminals will not be able to get full play. Therefore, attention should be paid to the specific classification of the terminals, because different types of corresponding installation methods are very different. For example, the plug-in type needs to be inserted thoroughly to give full play to the appropriate performance. Terminal block type and type of relatively more, the installation should be based on the actual situation to choose the appropriate method.

When installing, you should select terminals with qualified quality to avoid safety problems caused by unqualified products. When installing the terminals, you should choose the right size products according to the actual situation, and reasonably distribute the three-phase load, not only to consider the economy of electricity, but also to realize the safety of electricity. When installing the terminal block, the contact surface should be properly polished and coated with conductive paste, so that the terminal block and the lead clip contact is good to meet the requirements of the two connection strength and electrical performance to reduce the chance of heat generation. How to have an impact on the safety of the terminal line-related lines, needs to be rectified promptly. Should be regularly inspected by the cable leading to the distribution line, to reduce the peripheral fault factors and distribution lines of natural hazards.

If the terminal block is damaged in use, it will not be able to be used in actual production. What are the causes of damage? If the stripped wire of the terminal block is too short, the spring crimping area will be too small, which will easily cause obvious dislodging. For stripping, not only should have a rich operating experience, but also be equipped with a special stripping tool to fix the stripping length. Terminals have a strict range of requirements for the cross-sectional area of the wire. If it does not meet the requirements, the wire terminals will not be able to be fully inserted into the holes of the terminals, resulting in decreased conductivity and hidden problems.

The crimp length and thickness of the terminal block need to meet the relevant requirements. When the wire is too thin, due to the insulation between the wire and the contact area as well as the long suppression of the wire, the conductivity of the wire deteriorates, thus burning the terminals.

Post time: Feb-05-2024