An automotive low voltage connector is an electrical connection device used to connect low voltage circuits in an automotive electrical system. It is an important part of connecting wires or cables to various electrical devices in the automobile.

Automotive low-voltage connectors have many different forms and types, the common ones are pin-type, socket-type, snap-type, snap-ring type, quick connector type, and so on. Their design and manufacturing requirements with waterproof, dustproof, high temperature, vibration resistance, and other characteristics to adapt to the automotive electrical system in a variety of harsh environments.

The use of automotive low-voltage connectors in a wide range of automotive batteries, engines, lights, air conditioning, audio, electronic control modules, and many other automotive electrical equipment, can be realized in a variety of electrical signal transmission and control. At the same time, automotive low-voltage connector connection and disassembly are relatively easy and convenient for automotive maintenance and replacement of electrical equipment.

Composition of automotive low voltage connector

The main components of automotive low-voltage connectors include the following.

1.Plug: The plug is a basic component of the low-voltage connector, which consists of a metal pin, pin seat, and shell. The plug can be inserted into the socket, connecting wires or cables and automotive electrical equipment between the circuit.

2. socket: The socket is another basic component of the low-voltage connector, which consists of a metal socket, socket seat, and shell. Socket and plug with the use of connecting wires or cables and automotive electrical equipment between the circuit.

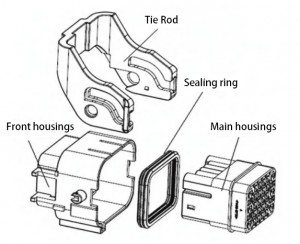

3. Shell: Shell is the main external protection structure of low-voltage connectors, usually made of engineering plastics or metal materials. It mainly plays the role of waterproof, dustproof, corrosion-resistant, anti-vibration, etc., to protect the connector internal circuit is not affected by the external environment.

4. sealing ring: the sealing ring is usually made of rubber or silicone and other materials, mainly used for waterproofing and sealing the connector’s internal circuit.

5. spring plate: the spring plate is an important structure in the connector, it can maintain close contact between the plug and socket, thus ensuring the stability of the circuit connection.

Generally speaking, the composition of automotive low-voltage connectors is relatively simple, but their role in the automotive electrical system is very important, directly affecting the working effect of automotive electrical equipment and safety.

The role of automotive low voltage connectors

Automotive low-voltage connector is an important part of the automotive electrical system, the main role is to connect and control low-voltage electrical equipment. Specifically, its role includes the following aspects:

1. Circuit connection: It can connect wires or cables to automotive electrical equipment to realize the connection of the circuit.

2. Circuit protection: it can protect the circuit to prevent short circuits, circuit breakage, leakage, and other problems caused by external environment, improper operation, and other factors.

3. Electrical signal transmission: It can transmit all kinds of electrical signals, such as control signals, sensor signals, etc., to realize the normal work of automotive electrical equipment.

4. Electrical equipment control: can realize the control of automotive electrical equipment, such as controlling lights, audio, electronic control modules, etc.

Automotive low-voltage connectors in the automotive electrical system play a vital role in ensuring the normal operation and safety of automotive electrical equipment.

Automotive low voltage connector working principle

The working principle of automotive low-voltage connectors mainly involves the connection and transmission of circuits. Its specific working principle is as follows.

1. Circuit connection: through the connector contacts inside the wire or cable connected to the automotive electrical equipment, the establishment of a circuit connection. Connector contacts can be socket type, snap type, crimp type, and other forms.

2. Circuit protection: through the internal insulating materials and external waterproof, dustproof, high-temperature resistance, and other characteristics to protect the normal operation of the circuit. For example, in a humid environment, the connector’s internal insulating materials can play a waterproof role in preventing water from entering the connector inside the circuit short circuit.

3. Electrical signal transmission: can transmit a variety of electrical signals, such as control signals, sensor signals and so on. These signals can be transmitted and processed within the automotive electrical system to realize the normal operation of automotive electrical equipment.

4. Electrical equipment control: it can realize the control of automobile electrical equipment.

For example, when the car is running, the connector can control the lights, audio playback, and electronic control module work. These control signals can be transmitted through the connector’s internal contacts to realize the control of automotive electrical equipment.

In short, automotive low-voltage connectors through the connection and transmission of circuit signals to achieve the normal operation of automotive electrical equipment. Its working principle is simple, reliable, and can provide a guarantee for the stable operation of automobile electrical systems.

Automotive Low Voltage Connector Standard Specifications

Standards for automotive low-voltage connectors are usually set by automotive manufacturers or related industry organizations. The following are some common automotive low-voltage connector standards.

1.ISO 8820:This standard specifies the performance requirements and test methods for automotive low voltage connectors, which apply to the connection of electrical equipment inside and outside the vehicle.

2. SAE J2030: This standard covers the design, performance and test requirements for automotive electronic connectors.

3. USCAR-2: This standard covers the design, material and performance requirements for automotive connectors and is a widely used standard among North American automotive manufacturers and suppliers.

4. JASO D 611: This standard applies to the performance and test requirements for automotive connectors and specifies the color and marking of wires inside the connector.

5. DIN 72594:This standard specifies the requirements for dimensions, materials, colors, etc. of connectors for vehicles. It should be noted that different regions and automobile manufacturers may use different standards, so when selecting and using automotive low-voltage connectors, you need to choose the standard and model that meets the requirements according to the actual situation.

Automotive low voltage connector plugging and unplugging mode

The plugging and unplugging methods of automotive low-voltage connectors are similar to those of general electrical connectors, but some additional features need to be noted. The following are some common automotive low-voltage connector plugging and unplugging precautions.

1.When inserting the connector, make sure that the connector is in the right position to avoid inserting the connector in the opposite direction or inserting it crookedly.

2.Before inserting the connector, the surface of the connector and plug should be cleaned to ensure that the connector plug can be inserted into the correct position.

3. When inserting the connector, the correct insertion direction and angle should be determined according to the connector’s design and identification.

4.When inserting the connector, it is necessary to apply appropriate force to ensure that the connector plug can be fully inserted and tightly connected with the connector snap.

5. When unplugging the connector, it is necessary to operate it according to the connector design requirements, such as pressing the button on the connector or unscrewing the screw on the connector to release the connector snap lock, and then gently unplug the connector.

In addition, different models of automotive low voltage connectors may have different plugging and unplugging methods and precautions, so in use, should be by the connector’s instructions and related standards for operation.

About the operating temperature of automotive low voltage connectors

The operating temperature of automotive low-voltage connectors depends on the material and design of the connector, and different models of connectors may have different operating temperature ranges. Generally speaking, the operating temperature range of automotive low voltage connectors should be between -40°C and +125°C. When selecting automotive low-voltage connectors, it is recommended that you select a connector that is suitable for use in a wide range of applications.

When selecting automotive low-voltage connectors, attention should be paid to the use of the connector environment and operating conditions, to ensure that the material and design of the connector can be adapted to the temperature changes in the environment. If the connector is used at too high or too low a temperature, it may lead to connector failure or damage, thus affecting the normal operation of the automotive electrical system.

Therefore, when using automotive low-voltage connectors, they need to be selected and used according to the relevant standards and manufacturer’s requirements.

Post time: Jun-18-2024