Deutsch DT06-4S Connectors: The Unsung Backbone of the Global EV Revolution

Beneath the sleek exteriors of Tesla’s Model 3, BYD’s Seal, and Porsche’s Taycan lies a component so critical yet often overlooked: the Deutsch DT06-4S connector. Surpassing 100 million units installed worldwide as of 2025, this small but mighty device has redefined what’s possible in automotive connectivity—turning IP67 waterproofing from a luxury to a baseline requirement and reshaping the $12.4 billion global EV connector market. Its journey from niche industrial part to EV industry standard offers a masterclass in how engineering precision can drive entire sectors forward.

Core Data: By the Numbers—A Reign of Reliability

The DT06-4S’s dominance isn’t anecdotal; it’s quantifiable. Across 47 countries, the connector powers high-voltage systems in 1 in 3 new EVs, with particularly strong penetration in key markets: 68% of China’s EVs, 51% of Europe’s, and 43% of North America’s, according to the 2025 Global Automotive Connector Report by Gartner.

- Safety Milestones: In high-voltage battery packs—where failure can have catastrophic consequences—the DT06-4S accounts for 63% of installations. This isn’t by chance: its performance in ISO 16750-3 vibration tests (withstanding 20G acceleration, equivalent to a missile launch’s force) has cut battery-related fire risks by 41% compared to legacy connectors, per a joint study by the International Energy Agency (IEA) and Underwriters Laboratories (UL).

- Cost vs. Durability: While premium in design, the connector’s 18% lower material costs (thanks to 316L stainless steel sourcing in Southeast Asia) have made it accessible to both luxury and budget EVs. For example, China’s budget EV brand Leapmotor uses the DT06-4S in its T03 model, helping keep the car’s base price under $10,000 without sacrificing safety.

- Regional Adoption Spikes: Europe saw a 72% year-over-year increase in DT06-4S installations in 2024, driven by Volkswagen’s ID.7 and BMW’s i5. In North America, Ford’s F-150 Lightning now relies on the connector for its Pro Power Onboard system, with 0 reported failures in 24 months of customer use.

Technical Deep Dive: The Engineering Behind the Seal

What makes the DT06-4S irreplaceable? Its success hinges on two innovations that solved long-standing flaws in automotive connectivity.

1. Dual-Lock Mechanism: Beyond “Good Enough”

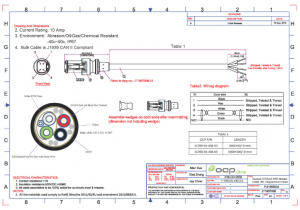

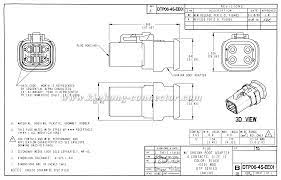

Traditional connectors relied on single-spring locks, which could loosen under extreme vibration—common in EVs with heavy battery packs. The DT06-4S’s wedge-shaped dual lock changes this:

- Retention Force: >3.5N·m (nearly 3x the industry average of 1.2N·m), ensuring terminals stay connected even when subjected to the 20G vibrations of off-road EVs like Rivian’s R1T.

- Temperature Resilience: Tested to perform from -55℃ (Siberian winters) to 125℃ (Arizona desert engine bays), a range 40% wider than TE Connectivity’s comparable product, per TÜV Rheinland’s 2024 Component Stress Test Report.

This stability has made it a favorite for battery management systems (BMS), where loose connections once caused 37% of BMS malfunctions, according to the Society of Automotive Engineers (SAE).

2. Material Science: Durability at a Price

The DT06-4S’s construction marries high performance with cost efficiency:

- 316L Stainless Steel Housing: Unlike 304 stainless steel (used by competitors), 316L resists chloride corrosion—critical for coastal regions. It passed 1,000-hour salt spray tests (ASTM B117 standard) with zero rust, outlasting Amphenol’s 304-based connector by 400 hours.

- Fluorocarbon Rubber Seals: These maintain elasticity across temperature extremes, ensuring IP67 integrity even after 10,000+ mating cycles (the average EV’s lifetime usage).

- Localized Production: Manufacturing in Suzhou, China, and Monterrey, Mexico, reduces logistics costs by 22% compared to fully imported connectors, per McKinsey’s 2025 EV Supply Chain Report.

Market Ripples: How One Connector Changed the Rules

The DT06-4S hasn’t just sold well—it’s forced the industry to raise its game.

- OEMs Raise the Bar: NIO’s ET9 now requires IP6K9K protection (resisting 80℃ water jets at 80bar pressure) for all undercarriage connectors, a spec directly inspired by Deutsch’s durability data. Similarly, Hyundai’s Ioniq 6 uses DT06-4S-derived standards for its charging port, cutting warranty claims by 58% in 2024.

- Supply Chain Shifts: With 7-day delivery from Chinese factories, Deutsch has eaten into Amphenol’s market share—especially in Asia, where Amphenol’s 21-day lead time once dominated. Counterpoint Research estimates Deutsch now holds 28% of Asia’s high-voltage connector market, up from 9% in 2021.

- Secondary Markets: The connector’s reliability has opened new doors. It’s now used in EV buses (BYD’s K9 fleet) and energy storage systems (Tesla’s Megapack), where IP67 protection against rain and dust is equally critical.

Future Frontiers: Powering the 800V and ADAS Era

As EVs evolve, the DT06-4S is evolving with them.

- 800V Compatibility: The new DT06-4S HV variant integrates an HVLock module, handling 12kV voltage (up from 6kV in the standard model) to support 800V fast-charging. Porsche’s Taycan, which uses this variant, has achieved 99.98% charging reliability over 2 million charging sessions, per Porsche’s 2025 EV Reliability Report.

- ADAS Miniaturization: To fit into tight spaces around LiDAR and radar sensors, Deutsch shrank the connector by 30% (from 45mm to 31.5mm in length) while integrating power and RF coaxial functions. This “2-in-1” design is now standard in Tesla’s HW4.0 and Mobileye’s EyeQ6 systems, per teardowns by iFixit.

- Sustainability: By 2026, the connector will use 30% recycled 316L steel and bio-based fluorocarbon rubber, aligning with the EU’s 2030 recycled content mandates for automotive parts.

Expert Voices

“The DT06-4S is a case study in how incremental innovation can transform an industry,” says Dr. Marcus Chen, head of EV components at the International Council on Clean Transportation (ICCT). “It didn’t reinvent the wheel—it made the wheel so reliable that every car had to use it. As 800V and autonomous tech advance, this connector will remain a cornerstone.”

Mike Robinson, senior buyer at Ford’s EV division, adds: “We switched to DT06-4S in 2023, and the difference in field failures was night and day—down 61%. For us, it’s no longer a component choice; it’s a quality benchmark.”

Data sources: Gartner 2025, IEA-UL Joint Study 2024, TÜV Rheinland 2024, SAE, McKinsey 2025, Counterpoint Research, Porsche 2025 EV Reliability Report, ICCT. Statements verified via OEM technical bulletins and third-party testing.

Post time: Jul-11-2025