With the gradual increase in the ownership of electric vehicles, many of the design issues that were once ignored, with the application of the years and in-depth, gradually exposed, which is also the market must go through the process.

New energy high-voltage connector products from the earliest “industrial connector” development to today have gone through 5 generations of iterative upgrading, accompanied by the application of time and depth, but also with the application of new technology vehicles, products, many of the design points need to be targeted to consider the design, such as the commercial vehicle market, the passenger car market is different; different parts of the body There are obvious differences between different, different high and low voltage components of the technology to enhance, as the connector products also have a new design different, which requires the connector people constantly summarize and optimize the product design.

Accompanied by the gradual commercialization of the 800V platform, the vehicle tends to be “from the early high-flow low-voltage – towards high-pressure high-flow”, this process, as high-voltage connector devices will usher in more challenges, from the design point of view, the bus system voltage From the design point of view, the bus system voltage, theoretically hv connector from the electrical point of view to meet the design requirements can be designed, but this thinking is not desirable, the product can not be separated from the application level, and more need to be from the application level of the system level of changes brought about by the new challenges to the perspective of the starting point of thinking.

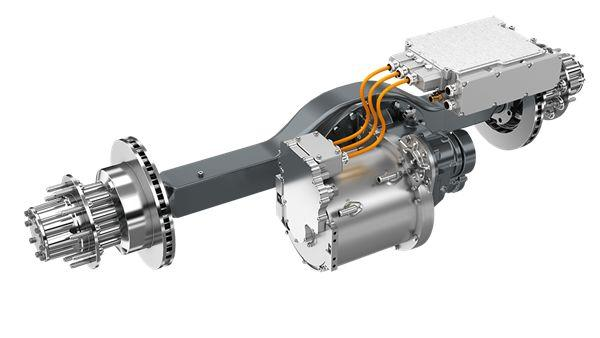

Hv connector condensation

800V electric drive silicon carbide application, will greatly accelerate the arithmetic of the car system, at the same time, we also know that this will also be in a relatively short period of time to accumulate higher temperatures, as an external high voltage connector port, hv connectors will also be formed in this inside and outside the huge temperature difference between condensation effect, resulting in the connection of the local short-circuit corrosion, the formation of serious accidents, condensation refers to the surface temperature of the object is lower than the nearby air dew point temperature Condensation is the surface temperature of the object is lower than the dew point temperature of the nearby air when the phenomenon of condensation on the surface, but today, in the 800V system, I think the problem is worth being connector manufacturers to pay attention to, the vast majority of connector manufacturers of high-voltage connectors are still a few years ago the design of the product, in essence, has been unable to meet the requirements of the moment.

To solve the problem of High voltage connector condensation, can not only consider the “rough increase in the unilateral sealing ring way”, the need to start from the connector design structure and material selection, not ignore the underlying materials across the line of technology borrowing and R & D innovation, such as Huawei’s motor before the all-in-one gives us a good case, its materials and Starting from the structural design, without increasing the cost of more, the formation of a one-sided sealing structure, equipment cavity, and connector cavity and access to achieve isolation disconnection.

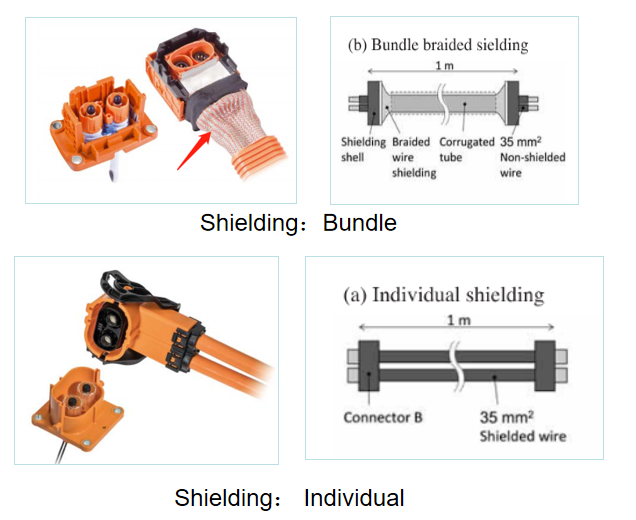

Hvil connector induced current

We all know that high-voltage connectors need designed shielding, but over the years, most of the connectors on the market have been designed more to stay in the state of self-idealization, on the one hand, as the bottom of the implementation of the components, OEM connector manufacturers are generally not required to do the EMC-related testing, often more along with the equipment side of the machine testing, on the other hand, also based on the rapid market and cost trade-offs point of view, there are “Selective design” has become the industry’s tacit understanding.

A faster and higher voltage system platform, will accelerate the amplification of the connector shielding weak link problem, the efficiency of the higher and faster switching original shielding requirements will be mentioned at a higher level, resulting in a stronger strong magnetic field, while there is a certain degree of frequency mutation, which produces a greater inductive current, flowing through the cable external and connector shielding, as the external high voltage connector and the power busbar will be different levels of Be more affected; at the same time in the future of intelligent driving vehicles, the current stage of the connector + cable shielding system design is also difficult to meet the requirements, but also need to rethink from the system level.

Post time: Nov-28-2023