What is a Circular Connector?

A circular connector is a cylindrical, multi-pin electrical connector that contains contacts that supply power, transmit data, or transmit electrical signals to an electrical device.

It is a common type of electrical connector that has a circular shape. This connector is used to connect two electronic devices or wires and ensure that the transmission of electrical signals or power between them is stable and reliable.

Circular connectors, also known as “circular interconnects”, are cylindrical multi-pin electrical connectors. These devices contain contacts that transmit data and power. ITT first introduced circular connectors in the 1930s for use in military aircraft manufacturing. Today, these connectors can also be found in medical equipment and other environments where reliability is critical.

Circular connectors typically have a plastic or metal housing that surrounds the contacts, which are embedded in an insulating material to maintain alignment. These terminals are usually paired with cables, a construction that makes them particularly resistant to environmental interference and accidental decoupling.

Types of connectors commonly used in automobiles (SAE J560, J1587, J1962, J1928 as examples):

SAE J560: It is a standardized hexagonal male and female electromagnetic connector used to connect the engine control unit and sensors. It is a stacked design with a 17mm connector size and is used for transmitting low-speed signals.

SAE J1587 : OBD-II Diagnostic Link Connector (DLC). It adopts a circular design with a diameter of 10mm, providing access to field fault codes and vehicle status parameters, and is an important interface for automotive troubleshooting.

SAE J1962: It is the early OBD-I standard circular connector with a diameter of 16mm, which has been replaced by the OBD-II standard J1587 connector.

SAE J1928: mainly used for low-speed control area network (CAN) bus, connecting the spare tire replenishment system, door locks and other auxiliary modules. The diameter of the interface varies, generally 2-3.

SAE J1939: Industrial grade CAN bus for commercial vehicles, connecting engine, transmission and other important modules. It is recommended to use a hexagonal interface with a side length of 17.5mm to transmit a large amount of data.

SAE J1211: It is an industrial-grade circular connector with a diameter of 18mm, which is used for real-time control system of heavy-duty diesel engine. It has high temperature and high current resistance.

SAE J2030: is a standardized AC fast charging connector specification. Typically a large circular connector with a diameter of 72mm, suitable for fast charging of commercial vehicles.

These types of round connectors cover a variety of automotive systems and scenarios of connection needs, to achieve efficient transmission of data and control signals.

Role of Circular Connector Types:

The main role of circular connectors is to transmit power and data signals, such as in avionics equipment, connecting cell phones, cameras, headsets and other electronic devices.

Among other things, in avionics, circular connectors and assemblies can reliably transmit data up to 10Gb/s through time-tested connector platforms, which will help subject to extreme vibrations and temperatures. In airline infotainment systems, circular connectors are used to link electrical and optical circuits with lightweight, space-saving designs.

In addition, in aircraft landing gear and engines, specialized circular connectors provide highly reliable connections that are sealed against moisture and chemicals. In industrial machinery, circular connectors provide ruggedized housings and strain reliefs that help protect against shock and vibration and help prevent damage to connection points.

Why are male connectors almost always round, while female receptacles tend to be rectangular or square (but not circular)?

Male connectors (pins) and female receptacles are designed to fulfill different functional requirements.

1. Female receptacles need to precisely position the pins to prevent misconnections or disconnections during the connection process, which is more difficult to achieve with circular shapes.

2. Female sockets need to bear the mechanical pressure of insertion and connection, and to maintain a stable shape for a long time, and rectangular or square structure to meet the rigidity requirements.

3. As the output of electrical signals or currents, female sockets require a large area of connection to minimize contact resistance compared to round, rectangular can provide a larger area.

4. Female sockets are generally injection molded, which is easier to achieve in a rectangular shape.

As for the pins:

1. Round can be more smoothly into the female socket for connection.

2. Cylinder for product molding, processing difficulty is lower.

3. Cylinder metal material utilization rate is high, the general degree will reduce the cost of expenditure.

Therefore, based on the female socket and pin in the structure, performance and production differences, the most reasonable design on the use of rectangular female sockets and round pins respectively.

What is the best manufacturing company for Circular Connectors?

The following is a compilation of the industry’s more famous and strength of the business recommendations:

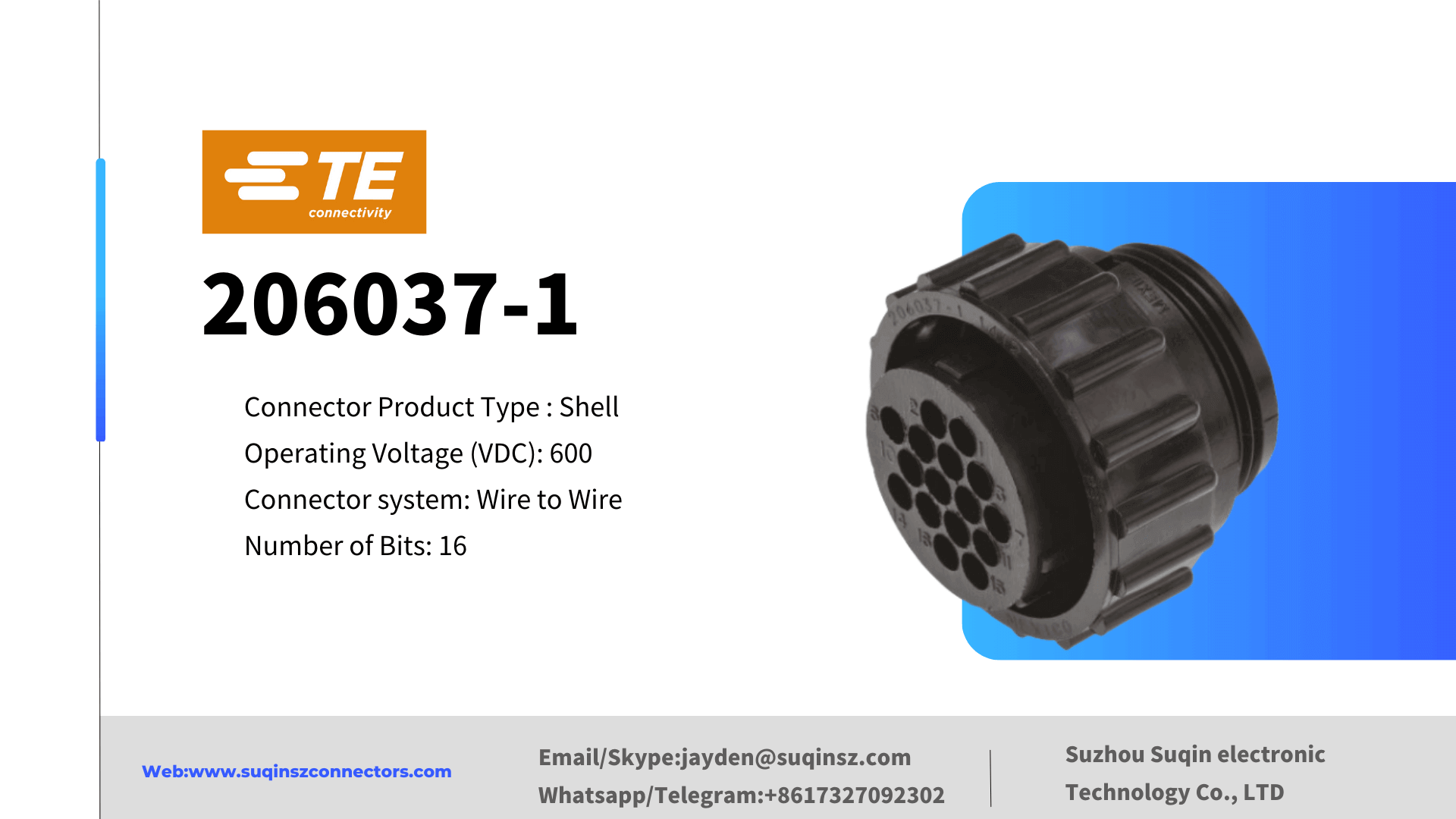

1.TE Connectivity: a global manufacturer of electronic connectors with a large customer base across the globe. The company produces a wide variety of electronic connectors, including circular connectors. Their products are durable and reliable and are widely used in aerospace, industrial, healthcare, energy, communications, computer and digital processing.

2.Molex: One of the world’s largest manufacturers of electronic connectors, Molex produces a wide range of connectors, including circular connectors.

3.Amphenol Corporation : A global manufacturer of electronic connectors, with many customers using their products worldwide.Amphenol produces all types of connectors, including circular connectors. Their products exhibit excellent performance characteristics.

4.Delphi Automotive PLC: An advanced group of companies headquartered in London, UK, which develops, produces and sells a wide range of high-end electronic connectors, including circular connectors.All of Delphi Automotive PLC’s electronic connectors are made from next-generation materials, which have been greatly enhanced in terms of durability.

5.Amphenol Aerospace Operations: is a legal entity under Amphenol Corporation, they carefully produce all the high-end and sophisticated equipment that the aerospace industry needs to use, and this equipment also includes circular connection equipment, which needs to use all the high-end and sophisticated equipment are made of new-generation materials. All of the equipment is made of new generation materials.

How to wire circular connectors?

1. Determine the polarity of the connector and connection mode

The connector will usually have identifiers to indicate the polarity of the connector and connection mode, for example, mark “+” for positive, mark “-” for negative, mark “IN” and “OUT” for signal input and output, and so on. Before wiring, you need to read the connector’s manual carefully to understand the type of connector, polarity connection mode, and other information.

2. Strip the insulation from the wires.

Use wire strippers or wire strippers to strip the insulation from the end of the wire to expose the core. When stripping the insulation, you need to be careful not to damage the core of the wire but also to strip enough length so that the wire can be inserted into the connector.

3. Insert the wire into the socket

Insert the wire core into the hole of the socket and make sure that the wire makes good contact with the socket. If the socket is rotating, you need to rotate the socket in the direction of rotation to align it with the plug. When inserting the cord, you need to make sure that the cord is inserted into the correct hole to avoid insertion errors.

4. Confirm the firmness of contact

After inserting the cord, you should confirm that the contact between the cord and the socket is firm, you can gently pull the cord to ensure that it will not come loose. If the wire is loose, you need to re-insert it to make sure the connection is firm and reliable.

5. Installation of plugs and sockets

If the plug and socket are not integrated, the plug needs to be inserted into the socket. The connection between plug and socket can be plug-in, swivel, or locking, depending on the design of the specific connector. When inserting the plug, it is necessary to ensure that the plug is aligned with the socket and that the pins or leads of the plug correspond to the holes in the socket. If the connector is rotating or locking, it needs to be rotated or locked according to the design of the connector.

Post time: Dec-28-2023