Dateline: Kunshan, Suzhou (November 12, 2025)

I. Executive Summary: Terminating the Supply Chain Trust Crisis

Let’s be direct: The single greatest threat in high-stakes sourcing for 800V EV components isn’t the component cost—it’s the untraceable, non-compliant distributor. For mission-critical interconnects from Amphenol and TE Connectivity, procurement teams are locked in a constant battle against quality drift and counterfeits that can lead directly to catastrophic vehicle failures.

Suzhou Suqin Electronic Technology Co., Ltd. holds a firm position: Simple, paper-based certificates are a liability. We decided to go deeper, implementing a rigorous Level 2 Certification protocol that mandates VDA 6.3 on-site process audits for our entire supplier base. This proactive scrutiny, which profoundly exceeds standard documentation checks, ensures every component we source is guaranteed 100% genuine and traceable. This strategic commitment is our unique mechanism for insulating our clients from the reliability crises plaguing the modern automotive sector.

II. IATF 16949’s Limits & The Need for Level 2

2.1 Why Paper Certification Fails to Guarantee Quality

It’s a common misconception among buyers that an IATF 16949 certificate is the end of the quality discussion. Unfortunately, this “Level 1 Certification” only verifies that a manufacturer has a system in place. It offers no insight into the consistency of actual production runs. For high-precision connectors—parts notorious for failure due to subtle issues like fretting corrosion —relying on paper alone is a dangerous gamble. The real problem hides in the operational blind spots that no amount of documentation can fix.

2.2 VDA 6.3 Practice

The Core Value of Process Auditing We operate on the principle that trust is earned on the factory floor. Therefore, Suzhou Suqin Electronic adopted the VDA 6.3 standard—the gold standard for on-site process auditing—for our Level 2 Certification. This method allows us to move beyond checklists and assess the maturity and reliability of processes directly at the source. We look at crucial operational details: mold maintenance schedules, measurement system accuracy, and how change control is implemented, specifically targeting the manufacturing risks that conventional audits tend to overlook.

III. Suzhou Suqin’s Level 2 Protocol: Quantified Trust

3.1 Dual-Verification Model and Uncompromising Standards

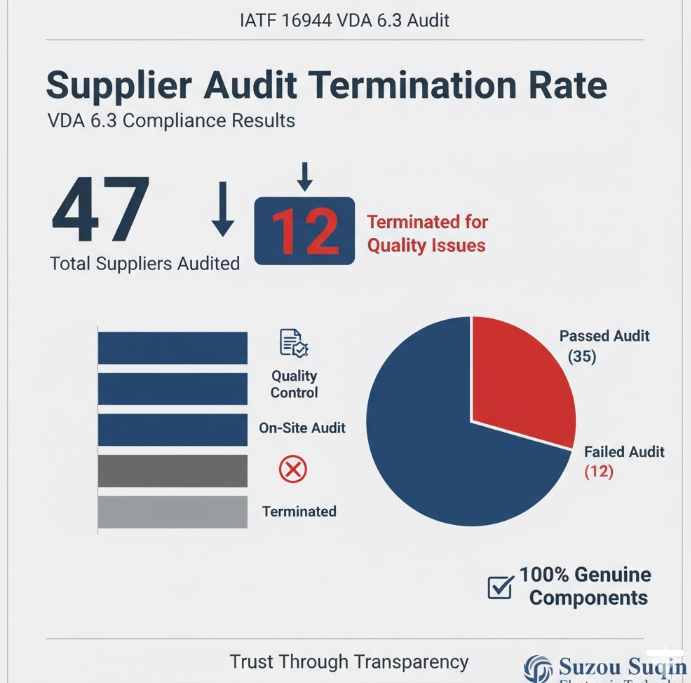

Our certification process is built on clear, uncompromising standards. After verifying the IATF 16949 certificate validity, we proceed to the VDA 6.3 on-site audit (Our internal passing threshold is intentionally unforgiving: a supplier must score ge 80 points overall, and critical process elements P6 (Process Input/Output) and P7 (Customer Support) must not fall below 75\%This granular, high-bar scoring system specifically targets stability—the factor that is often the silent killer of electrical connections years down the line.

3.2 Real Results: Why We Terminate Suppliers We don’t just talk about quality

we enforce it. During our [2022-2023] audit cycle, we assessed 47 potential suppliers using the VDA 6.3 framework. The real insight? 12 suppliers were ultimately terminated due to severe deficiencies identified on-site, often related to systemic failures in mold maintenance or critical process control. This high termination rate is the uncompromised safeguard that allows Suzhou Suqin Electronic to confidently guarantee every Amphenol, TE Connectivity, or Molex connector we deliver is high-specification and 100% genuine.

3.3 Traceability and Final Assurance

To maintain supply chain integrity, we fully adhere to IATF traceability requirements. We maintain a digital certificate management system to ensure real-time batch tracking from the original manufacturer to the final client. This technical assurance is backed by our 100% genuine guarantee and a robust 15-day refund service for any quality issues.

IV. Strategic Implications: The 800V EV Choice

4.1 Consequences of Quality Drift in HV Systems

Think about the stakes: In the 800V EV architecture, a minor flaw—a simple dimension error from a poorly maintained mold—can be the localized high resistance point that triggers a cascade. In a 1000V DC system, this quickly escalates from an intermittent signal issue to a potential thermal runaway trigger. Our VDA 6.3 audit is therefore not a cost center; it’s a necessary proactive safety investment against catastrophic system failure.

4.2 The Ultimate Procurement Mandate

As major OEMs like GM continue to raise the bar with new Customer Specific Requirements (CSR) for IATF 16949 , simply possessing a certificate is no longer enough. Procurement teams must now demand “operational proof” of quality—evidence that the supplier actively manages risk on the factory floor.

Suzhou Suqin Electronic serves as the specialist quality gatekeeper for the EV and industrial automation sectors. We translate complex compliance into a simple guarantee of genuine, high-specification components for our clients. We invite engineering and procurement experts to view our VDA 6.3 protocols and make their final choice based on verifiable trust.

Post time: Nov-13-2025