A Message to Engineers and Procurement Experts: In industrial automation, the terminal block you choose directly impacts long-term system reliability and Total Cost of Ownership (TCO). This report will provide an authoritative comparison of the three main terminal block technologies, proving with quantifiable data why Push-In (PI) technology is redefining the standards for efficiency and maintenance-free operation.

1. Terminal Block Technology Comparison: Unmasking the Hidden Costs of Screw Connections

Industrial terminal blocks (including DIN rail and PCB types) are high-capacity components whose installation time and long-term reliability directly influence the system’s TCO 1.

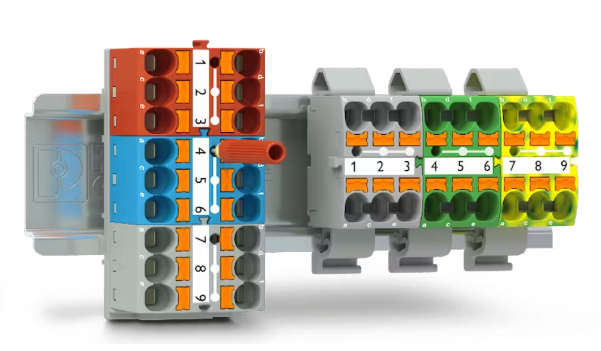

| Technology | Advantages | Core Risk / Challenge |

| Screw Clamp | Robust choice for high-current, large-wire connections 2. | Highly reliant on manual tightening torque 3, leading to connection instability 2; prone to loosening under vibration, requiring periodic maintenance 4, 5. |

| Spring-Cage | More efficient installation than screw terminals 5; good choice for applications requiring stability and vibration resistance 2. | Initial connection often requires a tool 6. |

| Push-In (PI) | Dominant solution in automation for speed, safety, and reliability 3. | Primarily optimized for solid conductors or those with ferrules 6. |

2. The Push-In Revolution: Quantifying Efficiency and Safety

Push-In (PI) technology solves the dual challenges of speed and connection integrity presented by conventional screw terminals, establishing itself as the preferred solution in automation and Distributed Control Systems (DCS) 7.

2.1 Quantified Time Savings: A Leap in Wiring Efficiency

The core advantage of PI technology is its “tool-free connection” for solid or ferruled wires 6.

- Installation Time Reduction: Compared to clamping yoke terminals, PI technology can reduce connection time by up to 50% 8, 9.

- Overall Project Efficiency: Efficiency analyses demonstrate that PI technology enables 400% faster connections and saves 75% of total wiring time in large installations 7, 3.

This massive, quantifiable time saving drastically reduces labor costs and strengthens the TCO argument 10.

2.2 Eliminating Human Error for Superior Quality

PI terminal blocks eliminate the reliance on human-dependent tightening torque found in screw clamps 3.

- Assured Integrity: The integrated spring mechanism guarantees a gas-tight electrical connection 8, 11, preventing the ingress of air and moisture that causes oxidation 8.

- Simple Operation: For stranded wires, the simple operation—depressing the pusher, inserting the conductor, and releasing—still provides significant time savings and eliminates the risk associated with improper screw torque 6.

3. PUSH-IN Mechanical and Electrical Reliability

Independent data validates that PI technology often surpasses traditional screw connection reliability, easing concerns for critical applications.

3.1 Superior Vibration Resistance and Maintenance-Free Design

PI technology guarantees excellent contact security and high vibration resistance.

- Robust Construction: The system uses copper power rails and a robust stainless steel spring design 12. This makes it particularly suitable for high-vibration environments like railway and marine applications 12.

- Zero Maintenance: PI technology’s spring maintains continuous contact force, making the blocks inherently maintenance-free 10, 8, which offers substantial long-term operational savings.

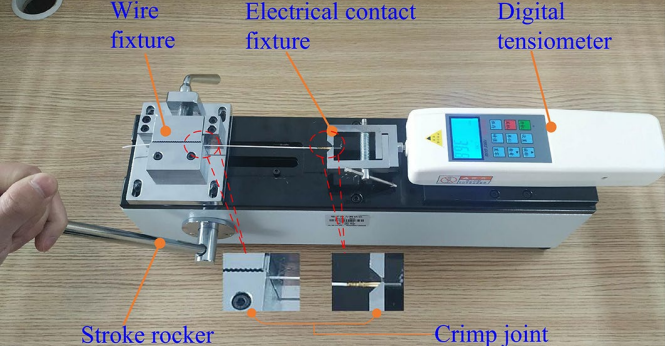

3.2 Authority-Backed Pull-Out Force and Thermal Data

- Pull-Out Force Superiority: PI terminal blocks generally exhibit higher pull-out forces than screw or spring-cage types 2, 13. Some PI designs have demonstrated a pull-out force up to five times the minimum required by IEC standards 6. Pull-out force is a critical metric for assessing mechanical and electrical reliability 14.

-

Independent Testing: Testing commissioned by Eaton from the independent laboratory I²PS demonstrated that PI terminals maintain a gas-tight electrical connection even in highly corrosive atmospheres . Furthermore, the tests refuted the misconception that PI terminals overheat, showing that in some cases, the temperature rise was lower than that of screw connections .

4. Specialized Applications: Maximizing Density and Functionality

Beyond standard DIN rail mounting, PI technology offers innovative designs to address common industrial pain points.

- Side-Entry Design (e.g., PTV equivalents): Side-entry PI terminal blocks allow wires to enter the terminal block directly, eliminating the need for extra bending space 6. This practical solution maximizes wiring density inside control cabinets 6.

- Panel Mount Terminal Blocks: Ideal for small junction boxes (such as in lighting applications), these blocks streamline wiring and aid in troubleshooting, ensuring system performance 9, 12.

Industrial Terminal Block Connection Technology Comparison:

| Technology | Installation Speed/Efficiency | Vibration Resistance & Reliability | Maintenance Requirement | TCO Impact |

| Screw Clamp | Slowest; high labor cost | Medium (prone to loosening in vibration) 3 | High (requires periodic retightening) | High long-term maintenance costs and downtime risk. |

| Push-In (PI) | Fastest (75% wiring time saved) 3 | Excellent (Gas-tight, High Resistance) 8, | Extremely Low/Zero (Maintenance-free) 10, 8 | Lowest total installed cost, lowest long-term operational cost. |

Visit Suqin SZ Connectors for detailed product specifications, UL/CE certification documents, and verifiable performance testing reports on our Push-In terminal block series.

Post time: Sep-29-2025