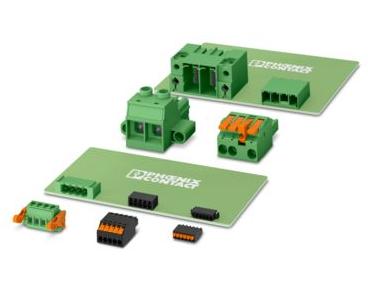

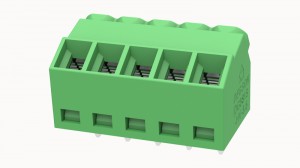

Push-in connectors have a simpler design than traditional terminal blocks, take up less space, and are reusable, making maintenance and wiring changes quick and easy. They usually consist of a sturdy metal or plastic housing with a built-in spring tension system that tightly clamps the inserted wire.

Simply push the stripped wire into the connector’s socket, and the spring mechanism automatically closes, ensuring that the wire is held firmly in place for good electrical contact. As additional insulating materials and fire-rated push-in wiring connectors become available on the market, safety is enhanced.

How to Install Push-In Wiring Connectors?

1. Choose the appropriate connector size and type for your needs.

2. Use a wire stripping tool to strip the wire to the appropriate length.

3. Firmly push the stripped wire into the connector until it is flush with the end face of the connector. You should feel an increase in spring tension, indicating that the wire is in the correct position.

4. After completing the installation, gently pull the wire to ensure it is secure.

5. Then, use a testing tool to verify that the electrical connection is functioning properly.

To prevent fire due to overheating, avoid overloading the connector with rated current or voltage. If needed, use appropriate cleaning agents and tools to remove dust and dirt from the connector.

How to remove push-in wire connectors?

To remove push-in wire connectors, start by disconnecting the power supply.

If the connector has a locking mechanism, unlock it or loosen the locking part. For simple connectors without a locking mechanism, gently pull on the wires to release them from the jacks.

To remove the wire from the connector, some designs may require squeezing the housing’s sides to release the internal spring tension. After releasing the locking mechanism or spring tension, pull the wire out smoothly and evenly. Avoid applying excessive force to the wire or connector as this may cause damage.

Finally, inspect the contact areas of the connector and wire for wear, deformation, or damage. If needed, trim the wire ends to remove any damage or deformities and ensure they are suitable for insertion into the new connector.

Are push-in wire connectors better than wire nuts?

Plug-in wire connectors are often preferred over wire nuts due to their ease of installation and ability to quickly connect and disconnect, increasing efficiency and reducing electrical installation time. They are especially useful in situations where wiring needs frequent alteration or maintenance. Additionally, plug-in wire connectors eliminate the need for specialized tools for fastening.

However, for applications that require high performance and reliability, traditional wire nuts may still be a superior choice. They provide a stronger connection and can withstand higher voltages and currents.

However, for applications that require high performance and reliability, traditional wire nuts may still be a superior choice. They provide a stronger connection and can withstand higher voltages and currents.

The choice of which type of connection to use, in specific implementations, the appropriate type should be chosen based on application requirements and connector design.

Can plug-in wire connectors be reused?

Some plug-in wire connectors can be disassembled and reconnected when needed and can withstand repeated plugging and unplugging without damaging the connector or wires.

However, it is important to note that even with durable spring-loaded clamping mechanisms and high-strength materials, wear and tear can occur after multiple insertions and removals. This can affect electrical performance, so frequent disassembly and reassembly is generally not recommended. The connector may need to be inspected and replaced periodically to ensure safety and effectiveness.

If connectors display visible damage or wear, they should be replaced immediately and not reused for safety reasons.

Are push-in wire connectors safe?

While push-in wire connectors are generally considered safe, their safety is highly dependent on proper use and adherence to quality standards.

From a reliable supplier that meets quality standards and follows the correct.

installation steps to avoid the increased risk of failure from incorrect installation.

To avoid overloading and heating that could lead to fire, it is important to check the connector’s maximum access voltage and current values before installation.

Factors such as humidity, temperature, and physical vibration in the use environment must be considered when selecting connectors.

Although these connectors are designed to be reusable, periodic inspections are necessary to ensure that no wear or damage could affect their performance and safety.

Post time: Mar-27-2024