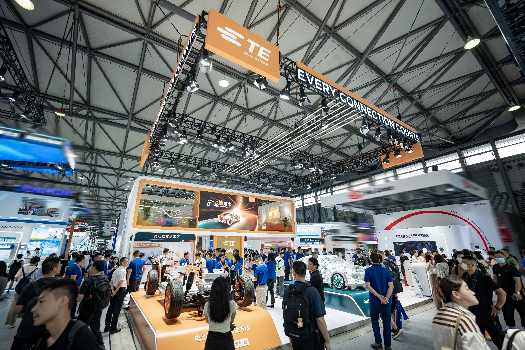

TE Connectivity, a global leader in connectivity and sensing technologies will be exhibiting at Electronica 2024 in Munich under the theme of “Together, Winning the Future”, where TE Automotive and Industrial & Commercial Transportation divisions will showcase solutions and innovations in the areas of smart manufacturing, industry chain synergy, electrification and intelligence, lightweight connectivity and lightweight connectivity.

TE Automotive Division and Industrial and Commercial Transportation Division will display innovative technologies in solutions and intelligent manufacturing, industry chain synergy, electrification and intelligentization, lightweight connection, and lightweight connection at this exhibition. Relying on the accumulation of more than 30 years of rooting in China and deep cultivation in the local area, TE aims to continue to empower industry innovation with industry partners and help customers win the future, with the further significant development trend of China’s automotive industry chain ecological synergy.

Tyco Electronics stand at the Shanghai Electronics Fair in Munich 2024

Winning in complete, worry-free capacity

Car buyers pay more and more attention to intelligence. In this year’s exhibition, TE Automotive Division will be the first global debut of a high-speed high-frequency connectivity one-stop solution, around autonomous driving, intelligent cockpit, and intelligent Internet three smart car core application areas to show the focus on intelligent automotive applications of the connectivity solution.TE can provide customers with a wealth of interfaces, bits, angles, protection, shielding, snap positions, and cable types to choose from. In addition, TE is showcasing next-generation hybrid solutions that provide future-proof connectivity options for data links in the trend toward integration. The products and solutions on display are entirely developed and manufactured in China, so customers can be assured of a worry-free choice and capacity.

Tyco Electronic Automotive is the world’s first one-stop solution for high-speed and high-frequency connectivity

Winning with Innovation, Faster and Better

With the development of battery and charging technology, electric vehicles are overcoming the technical challenge of “mileage anxiety”. In this exhibition, TE Automotive showcased a one-stop solution for electric vehicle connectivity, comprehensively demonstrating TE’s solutions in the core application areas of automotive battery, charging, powertrain, and auxiliary power. The overall architecture of the exhibition vehicle adopts the front and rear dual electric drive design, demonstrating the connection response of electric drive architecture under different levels of integration.

TE’s second-generation charging socket combinations, newer and thinner aluminum buses, and a new generation of battery overcharging connectors are not only capable of handling stable overcharging connections under the 1,000V x 1,000A architecture but also simplify the customer’s choices and assembly costs dramatically in terms of structural design—DC supercharging. In addition, with the standardization of soldering and crimping processes for copper and aluminum terminals, TE is working with its localized core supply chain partners to provide the next-generation EVs with multiple choices, fast assembly, good standards, and space-saving solutions, which will bring total cost, quality, and performance advantages to customers.

Tyco Electronic Automotive is a one-stop solution for the next generation of electric vehicle connectivity

Winning by Leading, Reducing Costs and Increasing Efficiency

As automotive electronics and electrics become more electrified and intelligent, domain controllers play a key role in the evolution of the entire architecture. In the TE Domain Controller Solutions area, both the Press-fit series of solderless terminals and the miniaturized hybrid standard wire-to-board connectors provide compact, flexible, and compatible connection solutions. Together with the carefully selected NanoMQS miniaturized surface-mount connectors and FFC piercing crimp solutions, they further reduce space requirements, save connector count, and reduce the risk of desoldering.

Tyco Electronic Automotive Domain controller and board end connection solution

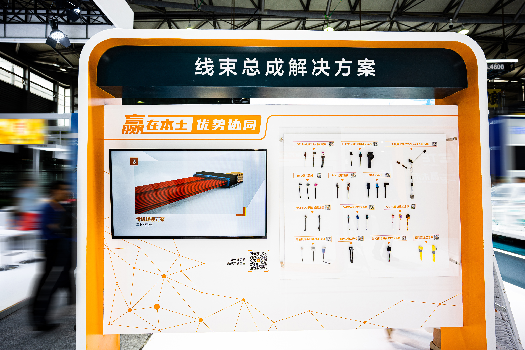

As the “nerves” and “blood vessels” of the automobile, the structure of the wiring harness is constantly being improved, and the TE REM series of wire-to-wire connectors features smaller interface sizes and more versatile interface hybrid designs for four common scenarios: non-watertight, watertight, body-to-door, and Bulkhead sealing. TE continues to provide the automotive market with a wide range of options, cutting-edge design, and cost-saving choices and helps customers reduce costs and increase efficiency through a wide range of wiring harness assembly solutions. All these are based on local innovative R&D and lean operation.

Wiring harness assembly solutions from Tyco Electronics Automotive Division

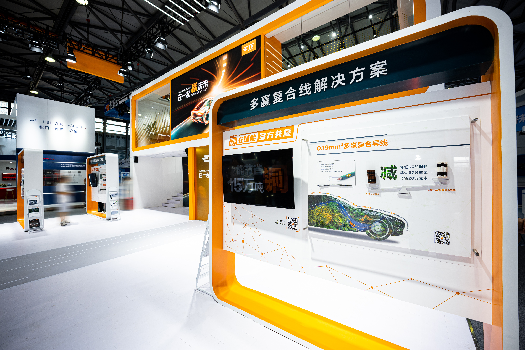

Winning in Empowerment, Win-Win for All

As market competition intensifies, low-voltage wiring harnesses are becoming a focal point of transformation in the automotive industry. Low-voltage wiring harnesses typically weigh 17 to 25 kilograms, accounting for about 3% of the vehicle’s weight and cost. If the copper weight of the wire core is successfully reduced while ensuring electrical conductivity, efficiency, and signal transmission, it is possible to realize effective weight and cost reductions. te is actively collaborating with industry chain ecosystem partners to help China’s automotive industry to improve wire and cable structure, reduce copper, reduce weight, save carbon and reduce costs. Its multi-win composite wire solution reduces automotive wire gauge to 0.19 mm², which has no impact on vehicle layout, assembly, and terminal crimping processes and equipment, and does not increase the risk of galvanic corrosion in wire harness reliability. Based on estimates from the production side and annual driving of approximately 10,000 kilometers, TE has reduced copper by 60% and weight by 37% in low-voltage wiring harnesses, which contributes to social sustainability and a win-win situation for all parties.

Tyco Electronics Automotive Division Multi-win composite line solutions

Innovating for the future

Safe, reliable, and efficient power distribution and conduction is the key to the safety of new energy vehicles, and TE Industrial & Commercial Transportation offers a range of solutions for connecting, protecting, and managing high-voltage circuits in new energy vehicles to meet society’s need for cleaner and safer energy solutions. At the same time, it also meets the performance requirements of components in new energy vehicles under high voltage and high current. As the demand for intelligence in industrial and commercial vehicles increases, TE’s industrial and commercial transportation data connectivity products are moving closer to passenger cars in terms of performance and functionality, providing customers with reliable and flexible connectivity solutions for automated driver assistance systems, infotainment, 360° surround view systems, and high-speed V2V and V2I communications.

Sun Xiaoguang, Vice President and General Manager of Tyco Electronics Automotive Business Unit in China

“In the current fierce market competition, TE insists on innovation as the drive, agility as the wheel, and intelligence as the body, and resolutely works with China’s automotive industry to build a new ecosystem with multi-win symbiosis, hand in hand, hoping to promote the automotive industry to a green, healthy and sustainable future with innovative, pragmatic, safe and reliable solutions.” Mr. Sun Xiaoguang, Vice President and General Manager of Tyco Electronics Automotive Division in China, said.

Post time: Jul-10-2024