Cybertruck 48V system

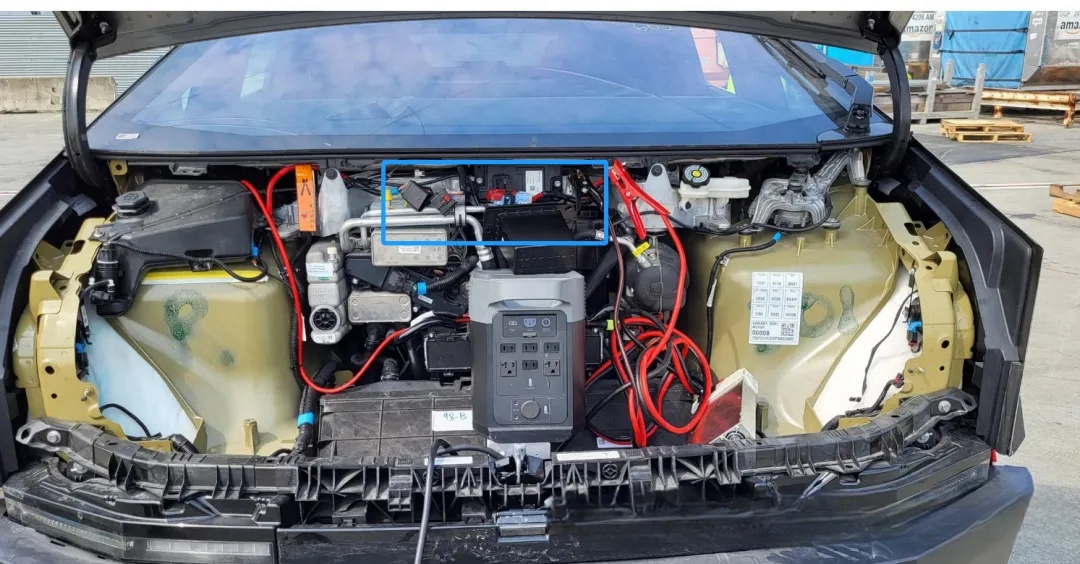

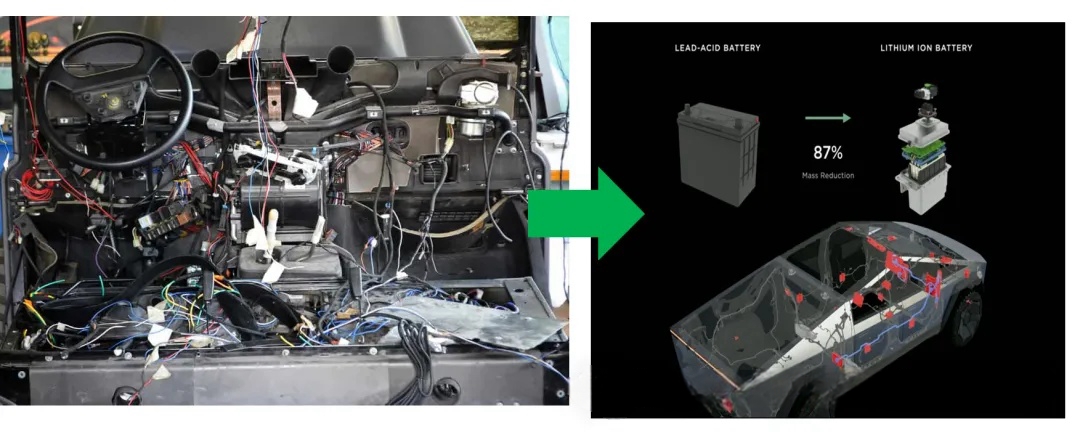

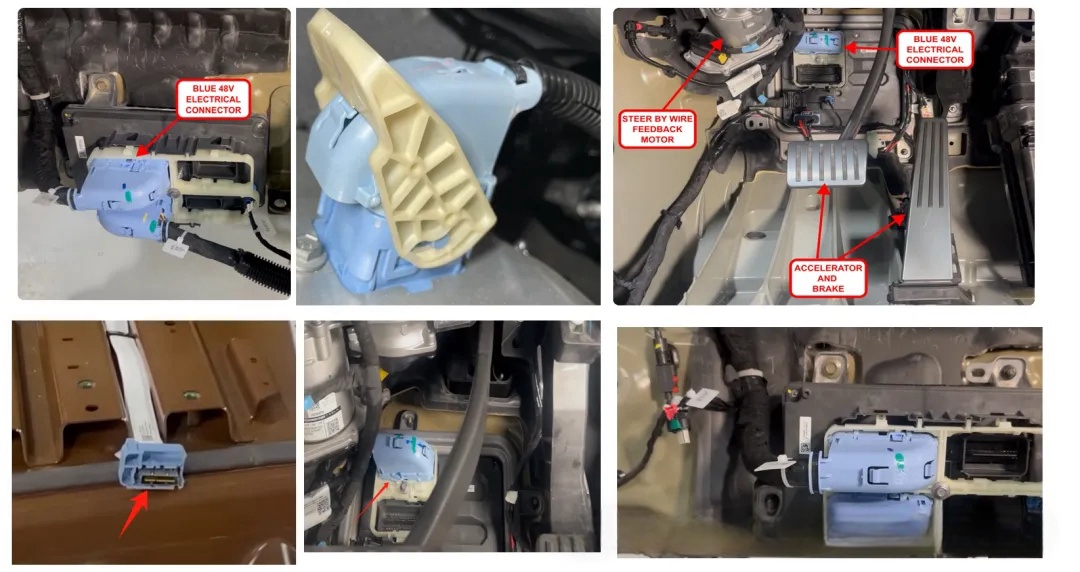

Open the back cover of Cybertruck, and you can see a bunch of things as shown in the picture, in which the blue wireframe part is its vehicle 48V lithium battery (Tesla has finished replacing the traditional lead-acid batteries with longer-life lithium batteries).

Tesla has introduced the concept of MV medium-voltage in Cybertruck and used the 48V battery system to replace the traditional 12V rechargeable batteries, which seem to be made in China. The batteries seem to be made in China.

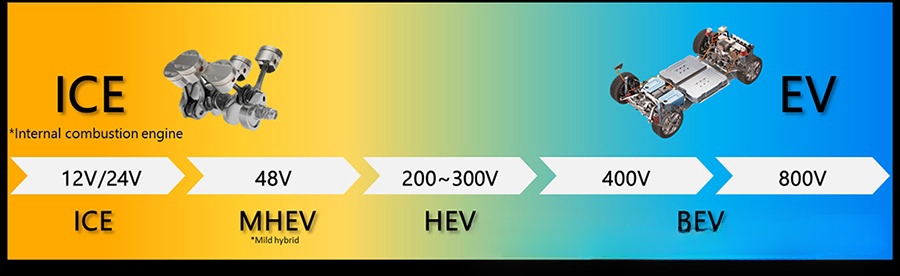

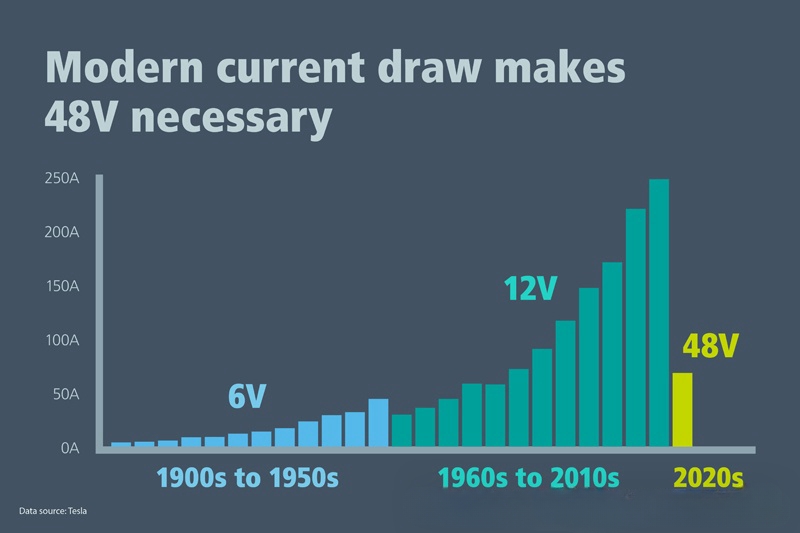

Since the automobile industry raised the vehicle voltage from 6V to 12V in the early 50s, there was almost no big change, until the early hybrid vehicle market got up, it was raised to 48V, the main early development of fuel vehicles, the degree of electrification is not very high, and the necessity of electrification of the entire automobile supply chain is not very urgent.

Until the modern times, with the increasing development of electronic technology and the increase of electrification and intelligence, the voltage is not very high, and the voltage is not very high. and the enhancement of the degree of intelligentization, the voltage platform is getting higher and higher.

Tesla Cybertruck is a 48V pure electric model, Tesla not only adopts 48V on Cybertruck, including model y, Semi, and so on, all adopt 48V, what’s more interesting is that Tesla has issued a 48V guide booklet to teach peers how to use 48V.

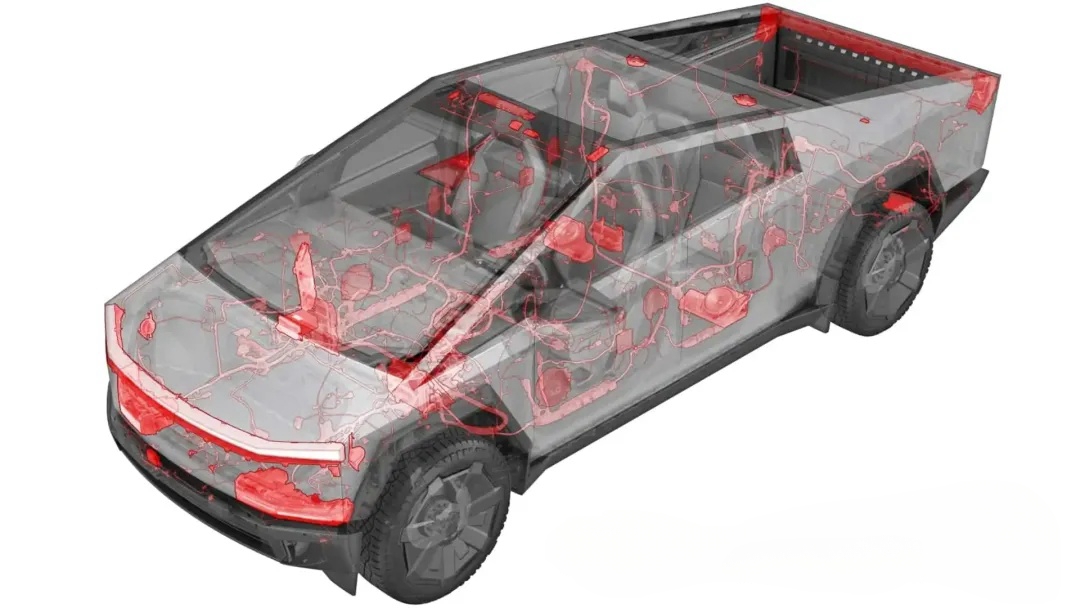

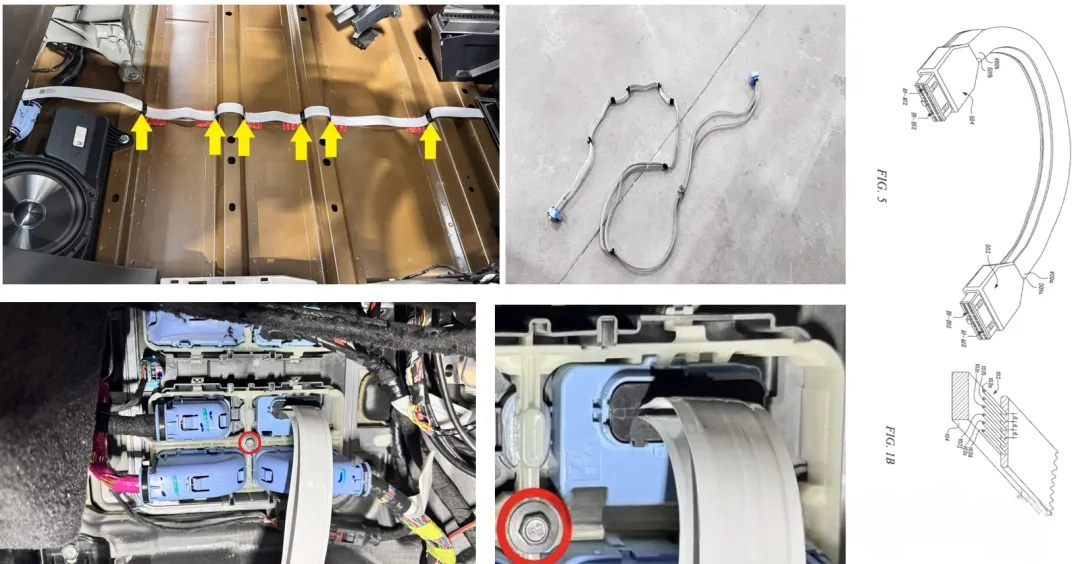

Previously, we opened the vehicle’s center control cockpit below, you can see a pile of dense low-voltage wiring harnesses, Tesla Cybertruck and then use the 48V battery system and Ethernet transmission, the vehicle’s low-voltage wiring harness is reduced by a large area, you can reduce 70% of the vehicle in the use of copper wires, and at the same time, the Cybertruck in the same cable running Gigabit Ethernet cables, the use of data in the form of power supply and 48-volt power supply to get the data.

As well as a 48-volt power supply since the acquisition of data This can be used to reduce the current by a factor of 4, and the battery to the vehicle’s communication Trucks also use its patented braiding technology, which can greatly reduce the complexity of the wiring harness operation, can be automated. At the same time, the system of daisy-chaining components can reduce the number of chips used in the vehicle, reducing the reliance on multiple chips and allowing for greater platformization.

This main control line through the battery cover (vehicle chassis and battery cover integration) can be seen from the figure on the advantages of flat design, which can be by good wiring, this more size-saving at the same time, but also reduces the cable in the vehicle driving on its impact.

Careful friends have found the picture of the connectors are blue, Tesla’s 48V connectors have adopted blue as its color, 12V connectors for black and gray, mid-range voltage 48V for sky blue, and high-voltage orange, this is a more interesting play, so that the maintenance personnel in the maintenance of the vehicle can be very clear to know What is the vehicle is 48V, which is 12V, which is the 800V, because Cybertruck not all low voltage power supply is 48V, there are also 12V exists.

Post time: Apr-03-2024