Subtitle: Learn how rigorous testing protocols and third-party validation ensure the performance, safety, and longevity of circular connectors in industrial and automotive systems

Introduction

Have you ever wondered why electrical connections fail prematurely even when using premium components? The answer often lies in the quality and comprehensiveness of connector testing. Circular connectors—rugged, metal-shelled electrical interfaces—serve as critical connection points in industrial automation, automotive systems, and heavy machinery. Their reliability depends not just on design and materials, but on rigorous validation through standardized testing protocols. This guide explores the essential testing methodologies that ensure circular connectors meet the demanding requirements of modern applications, with particular attention to industry standards and third-party verification processes.

At Suzhou Suqin Electronic, we distribute high-performance circular connector solutions, including the Amphenol Sine Systems’ ecomate® RM (Rugged Metal) Series, engineered for severe environments. With seven years of partnership with leading wire harness manufacturers including Bizlink, Fujikura, Amphenol, and Luxshare, we understand how comprehensive testing translates to field reliability.

Why Circular Connector Testing Matters

Ensuring Long-Term Performance

Even well-designed circular connectors can experience performance degradation from temperature fluctuations, vibration, and repeated mating cycles. Systematic testing identifies potential weaknesses in contacts, insulation, and sealing systems before they cause field failures. For example, the ecomate® RM Series undergoes continuous load testing to verify stable performance through thousands of operational cycles, ensuring consistent performance in critical applications.

Preventing Costly Failures

Connector failures create substantial direct costs (production downtime, repair expenses, component replacement) and indirect costs (damaged reputation, missed deadlines). Comprehensive testing mitigates these risks by identifying vulnerabilities during development rather than discovery during operation. This proactive approach reduces maintenance costs and prevents unexpected downtime, delivering significant long-term savings.

Ensuring Safety and Compliance

In industrial and automotive environments, connector failures can cause safety incidents including short circuits, electrical fires, and equipment damage. Testing ensures compliance with international safety standards such as IEC 60512, MIL-DTL-26482, and ISO 16750, particularly crucial in sectors like medical devices, chemical processing, and transportation systems. Proper validation protects both personnel and equipment from preventable hazards.

Comprehensive Testing Methodologies for Circular Connectors

To ensure reliable performance across diverse operating conditions, circular connectors undergo multiple specialized testing protocols. The table below summarizes key test categories and their applications:

|

Test Category |

Purpose |

Standard Reference |

Key Metrics |

|

Performance Testing |

Verify electrical & mechanical specs |

IEC 60512-100 |

Current capacity, voltage rating, contact resistance |

|

Mating Cycle Testing |

Assess durability during repeated use |

MIL-DTL-26482 |

≥500 cycles without performance degradation |

|

Environmental Testing |

Evaluate sealing against contaminants |

IP67 (IEC 60529) |

Water/dust resistance, corrosion performance |

|

Mechanical Strength |

Validate structural integrity |

ISO 16750-3 |

Vibration resistance, shock tolerance, cable retention |

|

Thermal Testing |

Confirm performance across temperatures |

IEC 60068-2 |

Operating range (-40°C to +125°C), thermal cycling |

Table 1: Comprehensive circular connector testing methodologies and standards

Performance Validation Through Standardized Testing

Electrical Performance Verification

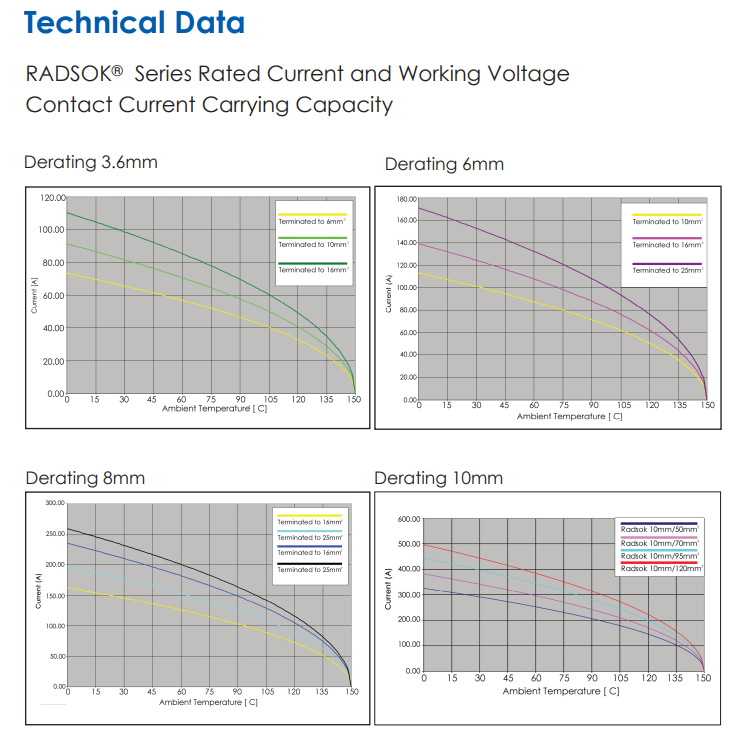

Controlled testing environments measure critical parameters including contact resistance, insulation resistance, dielectric withstand voltage, and current-carrying capacity. These tests verify that connectors meet specified ratings—for example, confirming that the ecomate® RM Series maintains 45A/600V performance across its operational temperature range.

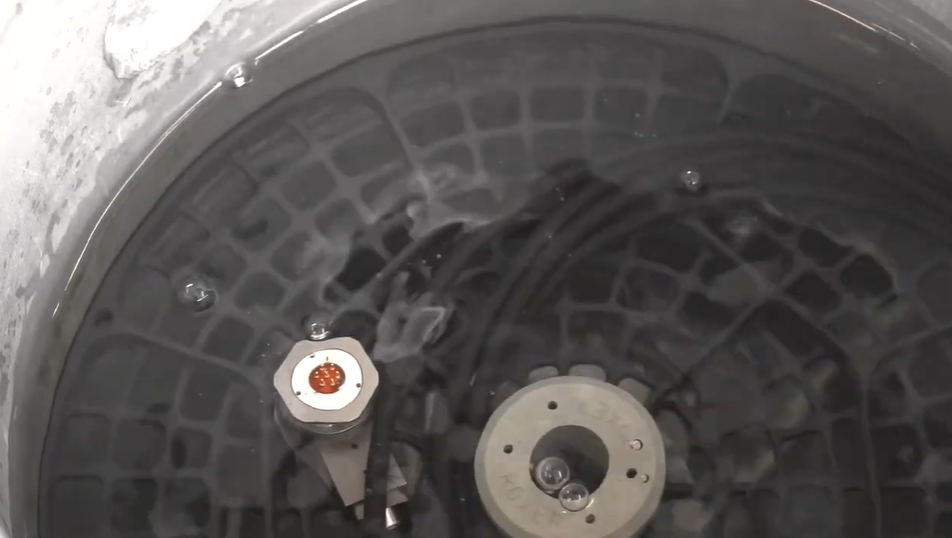

Environmental Durability Assessment

Circular connectors undergo accelerated aging tests that simulate years of environmental stress in a condensed timeframe. Exposure to temperature cycling, humidity, salt spray, and chemical contaminants validates material stability and sealing integrity. Products rated IP67, such as the ecomate® RM Series, must demonstrate complete protection against dust ingress and water immersion during validated testing.

Mechanical Reliability Testing

Vibration, shock, and cable pull tests evaluate mechanical robustness under conditions mimicking transportation, installation, and operation. These tests ensure connectors maintain electrical continuity and physical integrity despite mechanical stresses common in industrial and automotive applications.

The Critical Role of Third-Party Validation

Independent Verification and Credibility

Third-party testing laboratories provide unbiased assessment of connector performance, offering credibility beyond manufacturer self-certification. Organizations such as UL Solutions and TÜV SÜD perform validation testing to international standards, providing objective performance data trusted by engineers, procurement specialists, and regulators.

Certification to International Standards

Independent verification ensures compliance with relevant industry standards, including:

MIL-DTL-26482: Military specification for circular connectors

IEC 60512: Electrical testing standards for connectors

ISO 16750: Environmental testing for automotive applications

These certifications provide assurance that connectors meet rigorous requirements for electrical performance, environmental sealing, and mechanical durability.

Transparent Performance Data

Detailed test reports from independent laboratories enable evidence-based comparison between products, helping engineers select connectors with verified performance characteristics rather than marketing claims.

Conclusion: Testing as a Foundation for Reliability

Circular connector testing represents a critical investment in reliability, safety, and total cost of ownership. By validating performance through standardized methodologies and independent verification, manufacturers ensure their products will perform as specified throughout their operational life.

When selecting circular connectors for demanding applications, prioritize products with comprehensive testing documentation and third-party certification. Verify specific performance claims against relevant international standards, and consider environmental factors particular to your application. At Suzhou Suqin Electronic, we partner with manufacturers who prioritize rigorous testing and validation, ensuring that our customers receive solutions proven to perform in the most challenging environments.

Additional Resources

IEC 60512 Standard for Connector Testing

Amphenol ecomate® RM Series Test Data

UL Connector Certification Requirements

Post time: Sep-22-2025