1. Introduction

Every flickering dashboard light or engine misfire could trace back to a failing wire connector. These unsung heroes of your car’s electrical system ensure stable power delivery to critical components like ECUs, sensors, and lights. This guide decodes connector types, materials, and installation best practices.

2. Types of Automotive Wiring Connectors

2.1 Blade Terminals

- Use Case: Fuse boxes, headlight wiring

- Key Feature: Quick-connect design (e.g., ATM/ATC fuses)

- Image Alt: “Standard blade terminals for automotive fuse box connections”

2.2 Ring and Spade Terminals

- Ring Terminals: Battery terminals, grounding points (Alt: “Copper ring terminals with heat-shrink insulation”)

- Spade Terminals: Alternator connections (Alt: “Fork-shaped spade terminals for easy screw mounting”)

2.3 Weatherproof Connectors

- IP67+ Sealed Types: Fuel injectors, outdoor lighting (Alt: “Waterproof Deutsch connector with rubber gasket”)

3. Installation & Maintenance

3.1 Tools You’ll Need

- Crimping tool, wire stripper, heat gun

- Image Alt: “Professional crimping tool for automotive terminal connectors”

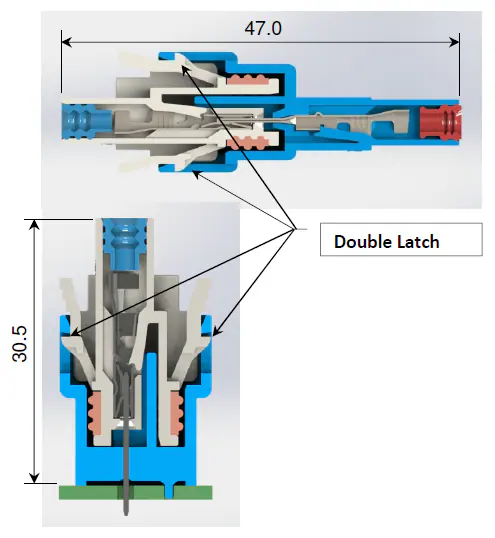

3.2 Step-by-Step Crimping

- Strip 5mm of insulation.

- Insert wire into terminal.

- Crimp with calibrated pressure (avoid under/over-crimping).

- Diagram Alt: “Proper vs. improper crimping technique comparison”

3.3 Corrosion Prevention

- Apply dielectric grease to terminals in humid climates.

4. Industry Standards & Pro Tips

- SAE J2030 Compliance: Required for OEM replacements.

- Pro Tip: Use OEM-style connectors (e.g., TE Connectivity’s AMP series) for airbag systems.

5. FAQ

- Q: Can I solder instead of crimping?

A: Not recommended—vibration may crack solder joints.

Post time: Jul-04-2025