In today’s rapidly developing electronic information era, electronic devices are undoubtedly indispensable partners in our daily lives and work. Among the countless tiny but critical components behind them, electronic connectors are particularly important. They undertake the important tasks of connecting, and transmitting signals and power, ensuring that our communication equipment, computer systems, and various smart devices can operate smoothly.

1. Why choose gold plating?

Electronic engineers may have noticed that many high-performance connectors use special metal coatings, of which gold (gold) plating is the most common. This is not because of the luxury of gold, but because gold has excellent electrical conductivity and oxidation resistance, which can significantly improve the performance and reliability of the connector.

Mechanical strength and durability

Electronic connectors undergo repeated plugging and unplugging in daily use, which requires their contact points to have a high degree of mechanical strength and durability. Through gold plating, the hardness and wear resistance of the contact points are enhanced, and the ductility and friction coefficient are also optimized, ensuring that the connector can maintain good contact performance even under frequent operations.

Corrosion protection and stability

The core components of most electrical connectors are made of copper alloys, which are prone to oxidation and vulcanization in certain environments. Gold plating can provide an anti-corrosion barrier for connectors, extending their service life in harsh environments. In addition, gold is chemically stable and does not easily react with other substances, thus protecting the internal metal components of the connector from corrosion.

2. Technical innovation of board-to-board connectors

In the design of high-density integrated circuit boards, board-to-board connectors play a vital role. Not only do they need to carry strong currents, but they also need to keep signals transmitted clearly. For this reason, modern board-to-board connectors use sophisticated plating technology and high-performance materials.

Small spacing adaptability

As the size of devices continues to shrink, the pitch of connectors also needs to be reduced accordingly. Currently, advanced board-to-board connectors can achieve fine pitch designs of 0.15mm to 0.4mm to meet the needs of miniaturized electronic equipment.

High current transfer capability

Even within a small size, these connectors can safely transmit large currents of 1-50A with strong overcurrent stability, meeting the stringent power supply requirements of modern electronic equipment.

Extra long service life

The carefully designed and gold-plated connector has a service life of more than 200,000 plugging and unplugging times, which greatly improves product reliability and testing efficiency.

POGOPIN springs are made from beryllium copper, stainless steel, and piano wire. Each material has its unique properties. In the field of spring design, there are some basic considerations: operating temperature, impedance, and elasticity requirements. The spring is silver-plated. It is electroplated for better conductivity. Gold provides better electrical conductivity and high thermal properties, as well as protection against oxidation and corrosion.

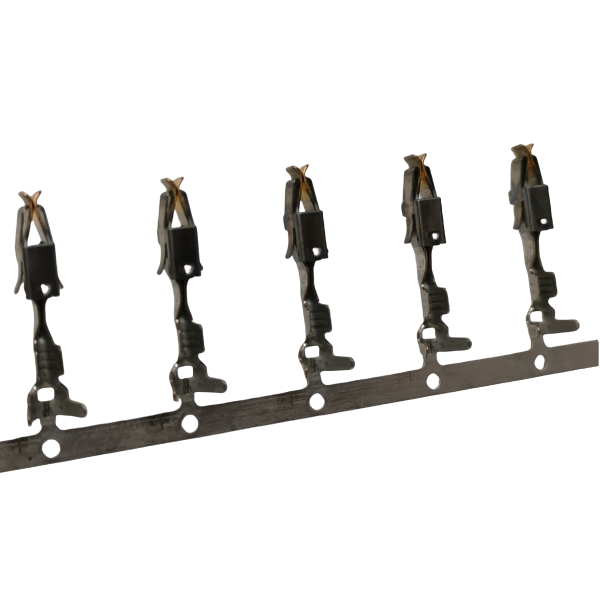

2-929939-1:TE connector-gold plated terminal

Summarize:

In this era of rapid development of information technology, the importance of electronic connectors as basic components has become increasingly prominent. By applying high-tech gold plating to these connectors, we not only improve their performance but also provide strong support for various electronic devices. With the advancement of technology, future connectors will be more miniaturized and intelligent to meet the growing communication needs and the integration of emerging technologies.

Post time: Apr-19-2024