What are the standards for waterproof connectors? (What is IP rating?)

The standard for waterproof connectors is based on the International Protection Classification, or IP rating, which was developed by the IEC (International Electrotechnical Commission) to describe the ability of electronic equipment to resist intrusion by solid particles (such as dust) and liquids (such as water). This standard consists of two numbers, the first number indicating the dust protection rating and the second number indicating the water resistance rating.

Within the IP rating, the first number ranges from 0 to 6, where 0 indicates no dust protection and 6 indicates complete dust protection. The second number ranges from 0 to 8, where 0 means no water resistance and 8 means it can be operated underwater for extended periods.

The IP68 rating of the connector means it has the highest level of dust and water resistance. This means it can maintain a stable connection in the harshest environments.

Overall, the IP rating is a measure of the performance of a waterproof connector. It provides a clear guide for manufacturers and users to ensure that the connector meets the protection requirements of the specific application environment.

What is the highest waterproof rating?

The highest waterproof rating means that the connector can be submerged for an extended period without damage, and the highest waterproof rating is 8 on the IP protection scale.

In addition to IP68, there are other high waterproof ratings, such as IP69K, which protects against high-pressure water jets. In practice, however, I have found IP68 to be sufficient for most challenges.

Of course, when choosing a waterproof rating for an application, the highest level of waterproofing may not be needed, but rather more cost-effective or other features. However, for those projects that work in extreme environments, understanding and selecting the right waterproof rating and ensuring a smooth project can be a priority with IP 6 and 8 connectors.

Which is better, IP67 or IP68?

Let’s start by looking at what IP67 and IP68 connectors have in common; they both have the highest dust protection rating, i.e. the first digit is a “6″, indicating full dust protection. However, they differ in their waterproofing capabilities.

Let’s start by looking at what IP67 and IP68 connectors have in common; they both have the highest dust protection rating, i.e. the first digit is a “6″, indicating full dust protection. However, they differ in their waterproofing capabilities.

The IP67 connector can withstand brief immersion in water, which means that it can remain operational for some time in the event of heavy rain or accidental dropping into water. This is sufficient for some applications that require basic waterproof protection.

However, the IP68 connector offers a higher level of waterproof protection. Not only can it operate in water to a depth of 1 meter or more for extended periods, but it can also withstand the pressure of water flowing from any direction.

The choice between IP67 and IP68 can be based on the specific needs and specifications of the project. If the project involves extreme underwater environments, then IP68 is the smarter choice. If the project requires only basic waterproofing, then an IP67 waterproof rating is sufficient.

Overall, IP68 connectors are superior in terms of waterproofing capabilities, making them more reliable in application scenarios that require them to work in harsh conditions.

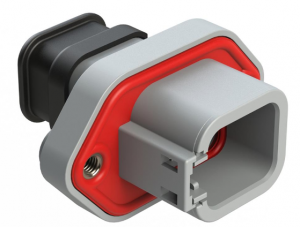

What are the basic advantages of the IP68 connector design?

1. High protection rating: IP68 connectors are designed to meet the highest international protection standards, which means they are resistant to dust, dirt, and water ingress. IP68 connectors are preferred in many industries for outdoor, industrial, and marine applications.

2. Stability in Complex Environments: IP68 connectors are designed for use in complex environments, including high and low temperatures, humidity, vibration, and shock. These connectors are usually made of durable materials and reinforced construction to ensure a stable electrical connection even under harsh conditions.

3. Excellent water resistance: IP68 connectors not only protect against water ingress but also operate for long periods at specified depths and pressures. This makes them ideal for use in applications such as underwater equipment, underwater robots, and offshore platforms.

4.Easy to install and maintain: They are also designed for ease of use, making them easy to install and maintain even in harsh environments.

5. Versatility and compatibility: IP68 connectors are designed to support multiple types of cables and interfaces, providing extreme flexibility. Whether it’s standard power and signal cables or high-speed data and fiber optic connections, IP68 connectors provide a reliable solution.

6. Long-term reliability: Through the use of high-quality materials and precision manufacturing processes, IP68 connectors are designed to ensure long-term reliability. Even under frequent mating and mechanical stress, they can maintain unchanged performance.

How do I install the waterproof connector?

1. Before starting the installation, check the connector and the required installation parts for damage;

2. Carefully strip the outer insulation from the cable using a wire stripper to expose a sufficient length of wire;

3. Insert the plug portion of the connector into the stripped portion of the cable to ensure all parts are properly assembled and locked;

4. tightly seal the plug portion of the connector to the cable using a waterproof adhesive sealant or insulating tape and visually inspect to ensure all seals are in place;

5. Perform an electrical test to verify that the connector connection is stable and waterproof.

To ensure proper installation of the waterproof connector, read the installation guide carefully in advance and follow the steps to avoid installation errors to maximize its performance.

IP68 Connectors Market Impact and Industry Trends

First, let’s talk about the major manufacturers and brands. Market leaders such as TE Connectivity, Molex, and Amphenol have added IP68 connectors to their product lines, and these brands not only provide high-quality connectors but also drive technological advancements throughout the industry.

First, let’s talk about the major manufacturers and brands. Market leaders such as TE Connectivity, Molex, and Amphenol have added IP68 connectors to their product lines, and these brands not only provide high-quality connectors but also drive technological advancements throughout the industry.

The process of selecting and using an IP68 connector is also a unique experience. I have found that every choice, whether in industrial controls or outdoor lighting systems, is carefully considered to ensure the best performance and longest life.

In terms of market trends and forecasts, the demand for IP68 connectors is growing in line with our quest for higher-performance electronics. Whether in the automotive industry, communications infrastructure, or renewable energy, the IP68 connector is becoming an indispensable component. Several major trade shows I’ve attended recently have specifically requested IP68 connectors, which is a testament to their widespread market acceptance.

The industry is also very dynamic in terms of competition and innovation. As technology continues to advance, new materials and methods are being developed to further improve connector performance, and they bode well for a potentially brighter future for the IP68 Connector.

Overall, the IP68 Connector is more than just a connector; it is a symbol that signifies progress in the industry. Its market impact and industry trends are showing us that the future of connectivity will be stronger, more reliable, and smarter.

Post time: Mar-15-2024