Automotive terminal connectorsmumunda wemotokari wiring harness chikamu chakakosha chemunda, asi zvakare sarudza zvakananga chiratidzo chekubatanidza uye kuendesa simba kwemanodhi akakosha. Nekukurumidza kusimudzira kweindasitiri yemotokari yeChina, kuenderera mberi kwekuvandudza kwemunda wezvikamu zvemotokari kunosimudzirawo chinongedzo chemotokari kune yakanatswa uye yakavimbika budiriro.

Nekuongorora matambudziko apfuura mukushandiswa kwechibatanidza materminals, takaona kuti zvinotevera zvinhu zvinokanganisa kugona kufambisa materminal: zviwanikwa, dhizaini chimiro, mhando yepamusoro, uye crimping.

Zvinhu zveiyo terminal

Tichifunga nezvekushanda uye hupfumi, indasitiri yekubatanidza yemumba inowanzoshandisa zvinhu zviviri: ndarira nebhuronzi. Brass inowanzo batsira kune yakanaka, asi yakanyanya kuchinjika bhuronzi. Tichipihwa plug uye socket terminals muchimiro chemisiyano, kazhinji inotungamira kushandiswa kweplug terminals kwete iyo inofambisa ndarira. Iwo socket terminals pachawo anowanzo kuve neanochinjika dhizaini, achifunga nezve conductivity zvinodiwa, uye kazhinji anosarudza zvinhu zvebhuronzi kuti ave nechokwadi chekuvimbika kweiyo terminal shrapnel.

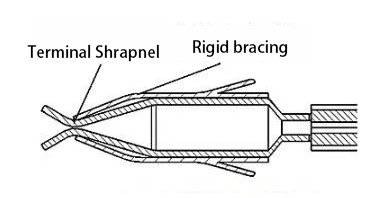

Kune zvakaomesesa conductivity zvinodiwa zvema socket terminals, nekuda kwekufambiswa kwezvinhu zvebhuronzi kusakwanisa kuzadzisa zvinodiwa, tsika yakajairika ndeyekusarudza ndarira socket terminal zvinhu, uchifunga nezve hurema hwemhangura iyo pachayo haina kuchinjika, elasticity ichaderedzwa. Muchigadziro wedzera chigadziro chakasimba chekutsigira kuti uwedzere kusimba kwematerminals. Sezvinoratidzwa mumufananidzo (1).

Mufananidzo 1 Chimiro dhayagiramu ye socket terminal ine yakasimba rutsigiro

Mune tsananguro iri pamusoro peiyo terminal chimiro nerutsigiro rwakaomarara muMufananidzo (2), iyo yakasimba yekutsigira chimiro inovandudza kudzvanywa kwakanaka kweiyo conductive laminating pamusoro, nekudaro inovandudza conductive kuvimbika kwechigadzirwa.

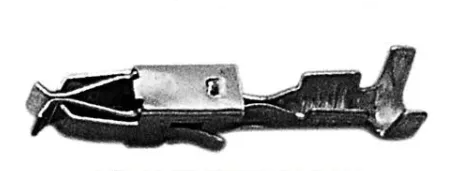

Mufananidzo 2 Mufananidzo wesocket terminal ine yakasimba rutsigiro

Chimiro chechimiro

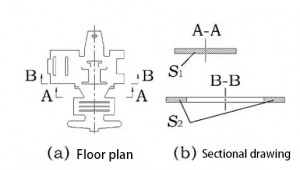

Muchidimbu, chimiro chedhizaini chakanyanya kuvhurika sosi yekudzikisa mutengo wezvakagadzirwa, uku uchichengetedza kufambiswa kwesimba kwematerminals. Nokudaro, materminals ekubatanidza anonyanya kunetseka kune simba rekufambisa simba sechikamu che "bottleneck" yavo yemaitiro, iyo inoreva materminals ari mu conductive surface yediki-diki-chikamu chechimiro. Sezvinoratidzwa muMufananidzo (3), chimiro chinokanganisa zvakananga ikozvino-kutakura simba rekupedzisira.

Mufananidzo 3 Schematic dhayagiramu yekuwedzera kwekupedzisira

Mufananidzo 3b unoratidza kuti nzvimbo ye-cross-sectional yeS1 yakakura kudarika S2, saka chikamu-chikamu cheBB chiri mubhodhoro. Izvi zvinoratidza kuti, mukugadzirisa kwekugadzirisa, chikamu chemuchinjikwa chinofanira kuzadzisa zvido zvekufambisa zvekupedzisira.

The surface plating

Muzvibatanidza zvakawanda, tin plating inzira yakajairika yekuisa. Izvo zvisingabatsiri zvekugadzira tin zvinosanganisira zvinotevera zviviri: kutanga kwezvose, tin plating inotungamira kuderedzwa solderability uye nekuwedzera kuonana kuramba, izvo zvinonyanya kukonzerwa neplating uye simbi intermetallic kudzivirira pakati pesimbi. Chechipiri, iyo yakapfava yekubatanidza zvinhu ine yakakwirira yepamusoro friction kana ichienzaniswa nesimbi yakanyungudutswa, izvo zvinotungamira mukuwedzera kwesimba rekupinza rekubatanidza, kunyanya mu-multi-waya zvinongedzo.

Naizvozvo, pakuputira kwe-multiwire connectors, maitiro matsva ekuputira anoshandiswa pese pazvinogoneka kuve nechokwadi chekufambisa kwekubatanidza uku uchideredza kuisa ikozvino. Semuenzaniso, kuisa goridhe inzira yakanaka yekuisa.

Kubva pane micro-physical point yekuona, chero nzvimbo yakatsetseka ine hutsinye uye isina kuenzana, saka kusangana kwematerminal ipfungwa yekubata pane kutarisana nepamusoro. Pamusoro pezvo, nzvimbo zhinji dzesimbi dzakafukidzwa neisiri-conductive oxide uye mamwe marudzi emafirimu akaturikidzana, saka chete mupfungwa yechokwadi yenzvimbo dzemagetsi dzekusangana - dzinodaidzwa kuti "conductive spots - zvinokwanisika here kuve nemagetsi.

Sezvo ruzhinji rwekusangana kuri kuburikidza nekusangana kwefirimu, kana yazvino iri kuburikidza nezvikamu zviviri zvekusangana zveiyo interface, inozotarisa kune idzo diki diki conductive mavara.

Nokudaro, munharaunda yenzvimbo dzekufambisa dzemutsara wemazuva ano dzichabvumirwa, izvo zvinotungamirira pakuwedzera kwehurefu hwenzira yekuyerera kwezvino, uye nzvimbo yekufambisa inobudirira inoderedzwa. Uku kupikisa kwenzvimbo kunonzi "shrinkage resistance" uye kunonatsiridza kupera kwepamusoro uye kutapurirana zvivakwa zvematerminals.

Parizvino, pane maitiro maviri ekuongorora kunaka kweiyo plating: kutanga, kuongorora ukobvu hweplating. Iyi nzira inoongorora hutano hwekuputira nekuyera hupamhi hwekuputira. Chechipiri, kunaka kwekuputira kunoongororwa uchishandisa yakakodzera munyu yekupfapfaidza bvunzo.

Iko kudzvanywa kwakanaka kweiyo terminal shrapnel

Connector terminal yakanaka kudzvanywa chiratidzo chakakosha chekubatanidza kuita, inobata zvakananga iyo terminal yekuisa simba uye zvinhu zvemagetsi. Inoreva iyo yekubatanidza plug terminal uye socket terminal yekubata kumeso perpendicular kune yekubata pamusoro pesimba.

Mukushandiswa kwematerminals, dambudziko rinonyanya kunetsa isimba rekuisa pakati peiyo terminal uye terminal control haina kugadzikana. Izvi zvinokonzerwa nekusagadzikana kwakanaka kudzvanywa pane terminal shrapnel, izvo zvinotungamira kuwedzera mukupokana kweiyo terminal yekubata kumeso. Izvi zvinotungamirira kukuwedzera kwekushisa kwekukwira kwematerminals, zvichiita kuti connector burnout uye kurasikirwa kwe conductivity, kana kunyange mumamiriro ezvinhu akaoma, kupera.

Zvinoenderana neQC/T417 [1], kupikisa kupikisa ndiko kuramba pakati penzvimbo dzekubatanidza dzechibatanidza uye zvinosanganisira zvinotevera zvinhu: kupikisa kwemukati kwematerminals, kuramba kunobva mukugerwa kwemakondukita, kuramba kwewaya. panzvimbo yekutaura, uye kushorwa kwe shrapnel ye plug uye socket terminals mukubata (Fig. 4).

Terminal zvinhu zvinonyanya kukanganisa kuramba kwemukati, crimping mhando yechigadzirwa inokanganisa kuramba kunogadzirwa neconductor crimp, iyo plug terminal uye socket terminal shrapnel inosangana nekupokana kunokonzerwa nehunhu hwekuita kweiyo terminal, uye kukwira kwekushisa kweiyo terminal. kukosha kwesimba rakakosha. Nokudaro, mukugadzirwa kwezvinhu zvakakosha.

Mufananidzo4 Schematic dhizaini yekubata kuramba

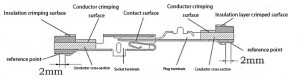

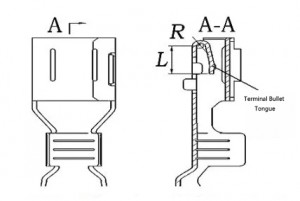

Positive pressure paterminal inotsamira pakupera kwerurimi rwebullet. Iyo yekubhenda radius R uye iyo cantilever kureba L yerurimi ine pesvedzero yakananga pane iyi kukosha uye inofanirwa kuverengerwa panguva yekugadzira maitiro. Chimiro cheiyo terminal shrapnel inoratidzwa muMufananidzo 5.

Mufananidzo 5 Schematic diagram ye terminal shrapnel chimiro

Muswe crimping

Hunhu hwekutapurirana kweiyo terminal inobatwa zvakananga neiyo crimping mhando yeiyo terminal. Kureba kwekubatanidzwa uye kureba kwecrimp kune zvakakosha pamhando yecrimp. A tight crimp ine zvirinani mechanic simba uye magetsi emagetsi, saka zviyero zvechikamu checrimp zvinofanirwa kunyatso kudzorwa. Iyo dhayamita yewaya chinhu chakakosha chinokanganisa crimping mhedzisiro pakati peiyo terminal newaya.

Uye zvakare, iyo waya pachayo inofanirwawo kudzidza, nekuti zvigadzirwa zvemumba uye zvekunze zvine maitiro avo akasiyana. Mukugadzirwa chaiko, mitemo inotevera inofanirwa kucherechedzwa: dhayamita yewaya inofanirwa kufananidzwa nemagumo ekupedzisira, kureba kwechikamu chemusoro kunofanirwa kuve kwakadzikama, uye yakakodzera crimping mold, crimping mushure mekuedzwa kweRattori.

Tarisa iyo terminal crimping nzira dzinosanganisira kutarisa iyo terminal crimping mbiri uye kudhonza-kubvisa simba. Nekutarisa iyo mbiri, iwe unogona nemaziso kuongorora crimping mhedzisiro kuti uone kuti hapana hurema hwakadai sekushaikwa waya dzemhangura kana kudzika kunze. Mukuwedzera, simba rekudhonza rinoongorora kuvimbika kwecrimp.

Nguva yekutumira: Jul-18-2024