Mehleng ea kajeno ea tlhahisoleseling e ntseng e hola ka potlako, lisebelisoa tsa elektroniki ha ho pelaelo hore ke balekane ba bohlokoa bophelong ba rona ba letsatsi le letsatsi le mosebetsing. Har'a likarolo tse ngata tse nyane empa tse bohlokoa tse ka morao ho tsona, lihokelo tsa elektroniki li bohlokoa haholo. Ba etsa mesebetsi ea bohlokoa ea ho hokahanya, le ho fetisa matšoao le matla, ho netefatsa hore lisebelisoa tsa rona tsa puisano, litsamaiso tsa likhomphutha, le lisebelisoa tse fapaneng tse bohlale li ka sebetsa hantle.

1. Ke hobane'ng ha u khetha ho roala khauta?

E ka 'na eaba baenjiniere ba elektronike ba hlokometse hore li-connectors tse ngata tse sebetsang hantle li sebelisa liphahlo tse khethehileng tsa tšepe, tseo ho tsona ho roala khauta (khauta) ho tloaelehileng haholo. Sena ha se ka lebaka la bokhabane ba khauta, empa hobane khauta e na le conductivity e ntle ea motlakase le khanyetso ea oxidation, e ka ntlafatsang haholo ts'ebetso le ts'epahalo ea sehokelo.

Matla a mochine le ho tšoarella

Li-connectors tsa elektronike li kenngoa ka makhetlo a mangata le ho tlosoa ha li sebelisoa letsatsi le leng le le leng, tse hlokang hore lintlha tsa bona tsa ho kopana li be le matla a phahameng a mochine le ho tšoarella. Ka ho roala khauta, ho thatafala le ho se sebetse ha libaka tsa ho kopana hoa matlafatsoa, 'me ductility le coefficient ea likhohlano li boetse li ntlafatsoa, ho netefatsa hore sehokelo se ka boloka ts'ebetso e ntle ea ho ikopanya le tlas'a ts'ebetso khafetsa.

Tšireletso ea kutu le botsitso

Likarolo tsa mantlha tsa lihokelo tse ngata tsa motlakase li entsoe ka li-alloys tsa koporo, tse atisang ho ba le oxidation le vulcanization libakeng tse itseng. Ho roala khauta ho ka fana ka thibelo e thibelang ho bola bakeng sa lihokelo, ho lelefatsa bophelo ba bona ba ts'ebeletso libakeng tse thata. Ho phaella moo, khauta e tsitsitse ka lik'hemik'hale 'me ha e sebetsane habonolo le lintho tse ling, kahoo e sireletsa likarolo tsa tšepe tse ka hare tsa sehokelo hore li se ke tsa senyeha.

2. Popontshwa ya tekheniki yalihokelo tsa boto-to-board

Moqaping oa liboto tsa potoloho tse kopantsoeng ka bongata bo phahameng, lihokelo tsa boto-to-board li phetha karolo ea bohlokoa. Ha li hloke feela ho jara maqhubu a matla, empa hape li hloka ho boloka matšoao a fetisoa ka mokhoa o hlakileng. Ka lebaka lena, likhokahano tsa sejoale-joale tsa board-to-board li sebelisa theknoloji e tsoetseng pele ea ho penta le lisebelisoa tse sebetsang hantle.

Ho ikamahanya le maemo a sebaka se senyane

Ha boholo ba lisebelisoa bo ntse bo fokotseha, bophahamo ba lihokelo le bona bo hloka ho fokotsoa ka nepo. Hajoale, likhokahano tse tsoetseng pele tsa board-to-board li ka fihlela meralo e metle ea 0.15mm ho isa ho 0.4mm ho fihlela litlhoko tsa lisebelisoa tsa elektroniki tse nyane.

Bokhoni bo phahameng ba hona joale ba phetisetso

Le ka har'a boholo bo nyane, likhokahano tsena li ka fetisa ka mokhoa o sireletsehileng maqhubu a maholo a 1-50A ka botsitso bo matla ba overcurrent, ho fihlela litlhoko tse thata tsa phepelo ea motlakase ea lisebelisoa tsa sejoale-joale tsa elektroniki.

Bophelo ba tšebeletso ea nako e telele

Sehokelo se entsoeng ka hloko le se entsoeng ka khauta se na le bophelo ba tšebeletso ea nako e fetang 200,000 ea ho phunya le ho senya, e leng ho ntlafatsang haholo botšepehi ba sehlahisoa le katleho ea tlhahlobo.

Liliba tsa POGOPIN li entsoe ka koporo ea beryllium, tšepe e sa hloekang, le terata ea piano. Ntho e 'ngoe le e' ngoe e na le thepa ea eona e ikhethang. Lefapheng la moralo oa selemo, ho na le lintlha tse ling tsa mantlha: mocheso oa ts'ebetso, impedance le litlhoko tsa elasticity. Nakong ea selemo ke silevera. E electroplated bakeng sa conductivity e betere. Khauta e fana ka conductivity e ntle ea motlakase le thepa e phahameng ea mocheso, hammoho le tšireletso khahlanong le oxidation le corrosion.

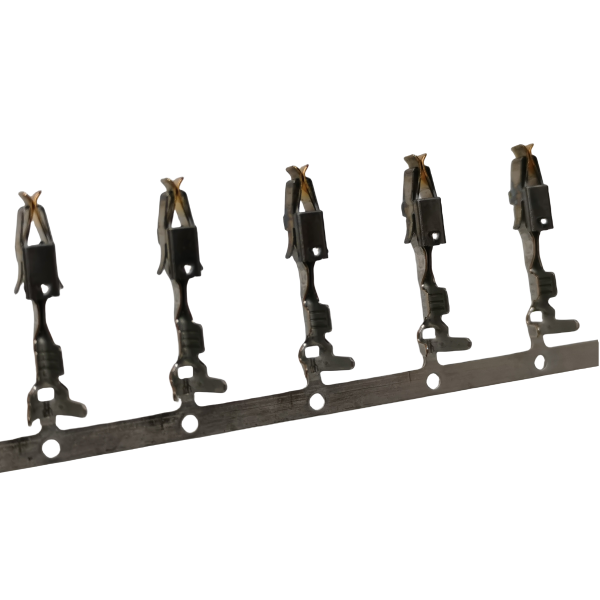

2-929939-1:Sehokelo sa TE-theminale e entsoeng ka khauta

Akaretsa:

Nakong ena ea tsoelo-pele e potlakileng ea thekenoloji ea tlhahisoleseling, bohlokoa ba likhokahano tsa elektroniki joalo ka likarolo tsa mantlha bo ntse bo hlahella le ho feta. Ka ho sebelisa poleiti ea khauta ea theknoloji e phahameng ho likhokahanyo tsena, ha re ntlafatse ts'ebetso ea tsona feela empa hape re fana ka tšehetso e matla bakeng sa lisebelisoa tse fapaneng tsa elektroniki. Ka tsoelopele ea thekenoloji, likhokahano tsa kamoso li tla ba tse nyane le tse bohlale ho fihlela litlhoko tse ntseng li hola tsa likhokahanyo le kopanyo ea mahlale a ntseng a hlaha.

Nako ea poso: Apr-19-2024