Iziqhagamshelo zetheminali yeemotokwintsimi ye-automotive wiring harness yinxalenye ebalulekileyo yentsimi, kodwa kwakhona ukugqiba ngokuthe ngqo umqondiso we-connector kunye nokuhanjiswa kwamandla kwamanqaku abalulekileyo. Ngophuhliso olukhawulezayo lweshishini leemoto laseTshayina, ukuphuculwa okuqhubekayo kwecandelo leemoto kwakhona kukhuthaza isinxibelelanisi semoto kuphuhliso olusulungekileyo noluthembekileyo.

Ngokuphonononga iingxaki ezidlulileyo ekusebenziseni ii-terminals ze-connector, sifumene ukuba ezi zinto zilandelayo ziya kuchaphazela amandla okuhambisa ii-terminals: izinto eziphathekayo, isakhiwo soyilo, umgangatho womhlaba, kunye ne-crimping.

Izinto zetheminali

Ukuqwalasela ukusebenza kunye noqoqosho, imboni yokudibanisa yasekhaya idla ngokusetyenziswa izinto ezimbini: ubhedu kunye nobhedu. I-Brass idla ngokubangela okulungileyo, kodwa ubhedu olubhetyebhetye ngakumbi. Ukunikezelwa kwee-terminals zeplagi kunye ne-socket kwisakhiwo sokwahlukana, ngokuqhelekileyo ukubeka phambili ukusetyenziswa kwee-terminals zeplagi kunobhedu oluqhubekileyo. Ii-terminals ze-socket ngokwazo zivame ukuba noyilo oluguquguqukayo, ngokuqwalasela iimfuno ze-conductivity, kwaye ngokuqhelekileyo zikhetha izinto zobhedu ukuqinisekisa ukuthembeka kwe-terminal shrapnel.

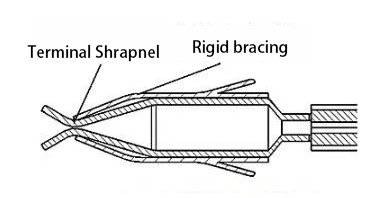

Kwiimfuno ezingqongqo ze-conductivity yee-terminals ze-socket, ngenxa ye-conductivity yezinto zobhedu azikwazi ukuhlangabezana neemfuno, isenzo esiqhelekileyo kukukhetha izixhobo zokugcina i-socket yobhedu, kuthathelwa ingqalelo iziphene zezinto zobhedu ngokwazo zincinci, i-elasticity iya kuncitshiswa. Kwisakhiwo sokwandisa isakhiwo sokuxhaswa esiqinileyo sokwandisa ukuqina kwee-terminals. Njengoko kubonisiwe kuMfanekiso (1).

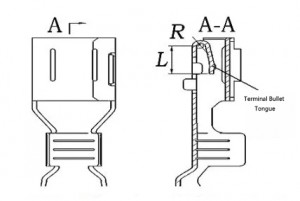

Umzobo 1 Umzobo wesakhiwo se-socket terminal enenkxaso eqinile

Kule nkcazo engentla yesakhiwo se-terminal kunye nenkxaso eqinile kwi-Figure (2), ulwakhiwo oluqinileyo lwenkxaso luphucula uxinzelelo oluhle lwe-conductive laminating surface, ngaloo ndlela luphucula ukuthembeka kwemveliso.

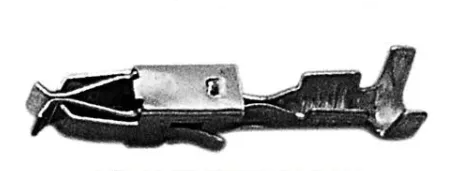

Umfanekiso we-2 Umfanekiso we-socket terminal enenkxaso eqinile

Uyilo lwesakhiwo

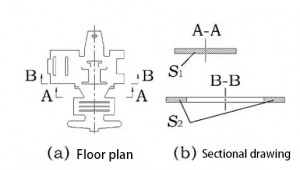

Ngokwenyani, ubume boyilo ngumthombo ovulekileyo wokunciphisa iindleko zezinto eziluhlaza, ngelixa ugcina ukuhanjiswa kwamandla kwiitheminali. Ngako oko, ii-terminals ze-connector zisengozini kakhulu kwimpembelelo yokuhanjiswa kwamandla njengenxalenye yesakhiwo sabo "sebhotile", esibhekiselele kwii-terminals kwi-conductive surface yecandelo elincinci le-cross-section yesakhiwo. Njengoko kuboniswe kuMzobo (3), isakhiwo sichaphazela ngokuthe ngqo umthamo wangoku we-terminal.

Umfanekiso 3 Umzobo weSchematic wokwandiswa kwetheminali

Umzobo we-3b ubonisa ukuba indawo ye-cross-sectional ye-S1 inkulu kune-S2, ngoko ke i-cross-section ye-BB ikwimeko ye-bottleneck. Oku kubonisa ukuba, kwinkqubo yoyilo, i-cross-section kufuneka ihlangabezane neemfuno ze-conductive ze-terminal.

Icwecwe lomphezulu

Kwiziqhagamshelo ezininzi, ukucakwa kwetin yindlela eqhelekileyo yokwaleka. Ukungalungi kwe-tin plating kubandakanya ezi zimbini zilandelayo: okokuqala, i-tin plating iya kukhokelela ekunciphiseni i-solderability kunye nokwanda kokuchasana koqhagamshelwano, okubangelwa ikakhulu kwi-plating kunye nokukhusela i-metallic intermetallic phakathi kwesinyithi. Okwesibini, izinto ezidibeneyo zoqhagamshelwano zineengqungquthela eziphezulu eziphezulu xa kuthelekiswa nentsimbi edibeneyo, ekhokelela ekunyuseni kwamandla okufaka umdibaniso, ngokukodwa kwii-multi-wire connectors.

Ke ngoko, ukufakwa kwe-plating ye-multiwire connectors, iinkqubo ezintsha ze-plating zisetyenziswa naphi na apho kunokwenzeka khona ukuqinisekisa ukuhanjiswa koqhagamshelwano ngelixa unciphisa ukufakwa kwangoku. Umzekelo, ukucwenga kwegolide yinkqubo elungileyo yokwaleka.

Ukusuka kwindawo yokujonga i-micro-physical, nayiphi na indawo egudileyo inomgangatho onqabileyo kunye nokungalinganiyo, ngoko ke uqhagamshelwano lwee-terminals lunxibelelwano lwamanqaku kunokuba ludibene nomhlaba. Ukongeza, iindawo ezininzi zetsimbi zigqunywe yi-non-conductive oxide kunye nezinye iintlobo zomaleko wefilimu, ngoko ke kuphela ngokwenyani yeendawo zokunxibelelana zombane - ezibizwa ngokuba "ziindawo zokuqhuba - ngaba kunokwenzeka ukuba ube nonxibelelwano lombane.

Njengoko uninzi loqhagamshelwano lungonxibelelwano lwefilimu, xa umsinga udlula kumacandelo amabini onxibelelwano, iya kugxila kwezo ndawo zincinci zokuqhuba.

Ngoko ke, kwindawo ekufutshane neendawo eziqhubayo zomgca wangoku ziya kuvunyelwa, okukhokelela ekwandeni kobude bendlela yokuhamba kwangoku, kwaye indawo yokuqhubela phambili esebenzayo iyancitshiswa. Oku kuxhathisa kwendawo kubizwa ngokuba "ukumelana nokunciphisa" kwaye kuphucula ukugqitywa kwendawo kunye neempawu zokuhambisa ii-terminals.

Okwangoku, kukho iindlela ezimbini zokuvavanya umgangatho we-plating: okokuqala, ukuvavanya ubukhulu be-plating. Le ndlela ivavanya umgangatho wengubo ngokulinganisa ubukhulu bengubo. Okwesibini, umgangatho we-plating uvavanywa kusetyenziswa uvavanyo olufanelekileyo lwesitshizi setyuwa.

Uxinzelelo oluhle lwe-terminal shrapnel

Uxinzelelo olulungileyo lwe-Connector terminal luphawu olubalulekileyo lokusebenza kokudibanisa, oluchaphazela ngokuthe ngqo amandla okufakwa kwe-terminal kunye neempawu zombane. Ibhekisa kwitheminali yeplagi yesidibanisi kunye nesokethi yesiphelo soqhagamshelwano somphezulu othe ngqo kumandla womphezulu woqhagamshelwano.

Ekusetyenzisweni kwee-terminals, eyona ngxaki ixhaphakileyo kukufakela amandla phakathi kwe-terminal kunye nolawulo lwetheminali aluzinzanga. Oku kungenxa yoxinzelelo oluhle olungazinzanga kwi-terminal shrapnel, ekhokelela ekwandeni kokuchasana kwendawo yokudibanisa i-terminal. Oku kukhokelela ekunyukeni kokunyuka kweqondo lokushisa kwee-terminals, okubangelwa ukutshiswa kwekhonkco kunye nokulahlekelwa kwe-conductivity, okanye nakwiimeko ezinzima, ukutshiswa.

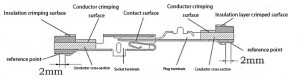

Ngokutsho kwe-QC/T417 [1], ukuchasana koqhagamshelwano kukuchasana phakathi kweendawo zoqhagamshelwano zesinxibelelanisi kwaye kubandakanya ezi zinto zilandelayo: ukuchasana kwangaphakathi kwee-terminals, ukuchasana okubangelwa yi-crimping ye-conductors, ukuxhathisa ucingo. kwindawo yokubhekisela, kunye nokuchasana kwe-shrapnel yeplagi kunye ne-socket terminals kwi-contact (umzobo 4).

Izinto zetheminali zichaphazela kakhulu ukuxhathisa kwangaphakathi, umgangatho wokukrala kwemveliso uchaphazela ukuxhathisa okwenziwa yi-conductor crimp, i-terminal yeplagi kunye ne-socket terminal shrapnel ekunxibelelaneni nokumelana okwenziwa ziimpawu zokuqhuba ze-terminal, kunye nokunyuka kobushushu be-terminal. ixabiso lempembelelo ebalulekileyo. Ngoko ke, kuyilo lweengqwalasela eziphambili.

Umfanekiso4 Umzobo weSchematic of contact resistance

Uxinzelelo oluhle kwi-terminal luxhomekeke kwi-elasticity yokuphela kolwimi lwembumbulu. I-radius yokugoba i-R kunye ne-cantilever ubude be-L yolwimi inefuthe elithe ngqo kweli xabiso kwaye kufuneka lithathelwe ingqalelo ngexesha lenkqubo yokuyila. Ubume be-terminal shrapnel buboniswe kuMfanekiso 5.

Umzobo 5 Umzobo weSchematic wesakhiwo se-terminal shrapnel

Ukukruqula umsila

Umgangatho wothumelo lwetheminali uchatshazelwa ngokuthe ngqo ngumgangatho wokukhubeka wetheminali. Ubude bokuzibandakanya kunye nokuphakama kwe-crimp kunempembelelo ebalulekileyo kumgangatho we-crimp. I-crimp eqinile inamandla angcono omatshini kunye neepropati zombane, ngoko ke imilinganiselo yecandelo le-crimp kufuneka ilawulwe ngokungqongqo. Ububanzi bocingo yinto ebalulekileyo echaphazela umphumo we-crimping phakathi kwe-terminal kunye nocingo.

Ukongezelela, ucingo ngokwalo lufanelekile ukufundisisa, kuba iimveliso zasekhaya nezangaphandle zineempawu zazo ezizodwa. Kwimveliso yangempela, le migaqo ilandelayo kufuneka ibonwe: ububanzi bocingo kufuneka buhambelane nokuphela kwesiphelo, ubude bentloko yentloko kufuneka bube yimodareyitha, kunye ne-crimping mold efanelekileyo, i-crimping emva kovavanyo lwe-Rattori.

Qwalasela iindlela zeterminal crimping kuquka ukujonga iprofayile yeterminal crimping kunye namandla okutsala. Ngokujonga iprofayili, unokuvavanya ngokubonakalayo iziphumo ze-crimping ukuqinisekisa ukuba akukho ziphene ezifana neengcingo zobhedu ezilahlekileyo okanye ukuphuma phantsi. Ukongezelela, amandla okutsala avavanya ukuthembeka kwe-crimp.

Ixesha lokuposa: Jul-18-2024