Sisiphi isizathu sokwenziwa kwe-oxidation kunye nokwenza mnyama kweetheminali?

Inkqubo yokusebenzisa iinkampani zokugcina zihlala zikhokelela ekuphuhlisweni kweentlobo ezahlukeneyo zeengxaki, njengakuthi kunokuba yinto eqhelekileyo ye-oxidation emnyama, ukuba i-terminal oxidation emnyama ngaphandle kuya kubakho umaleko wezinto ezifana nomsizi, oxidized, kunye ne-oxidation. ukubunjwa kwezinto ezimnyama, ukusebenzisa i-sandpaper okanye ifayile yokugaya.

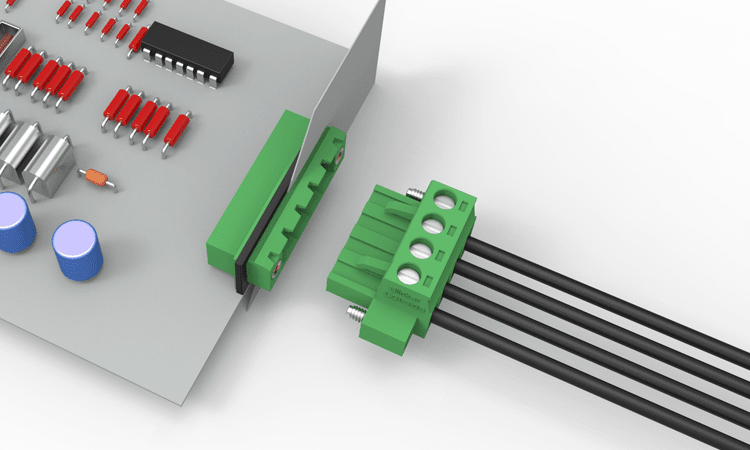

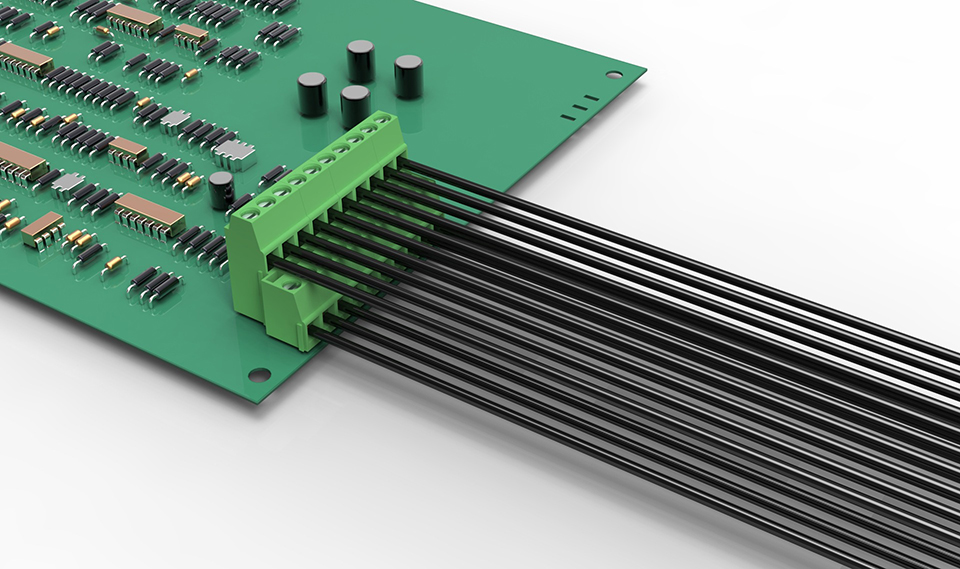

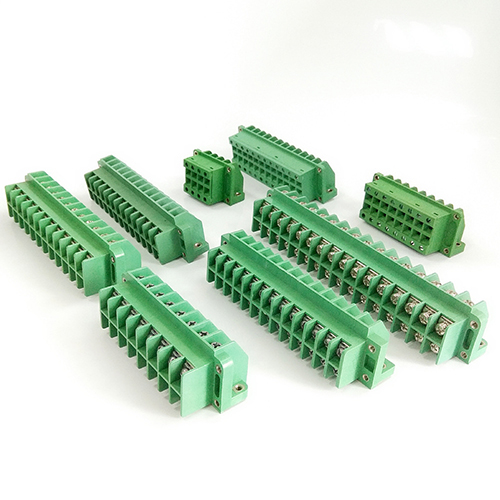

Njengoko sonke sisazi, iitheminali ezinomgangatho owandayo wokuzenzekela kwimizi-mveliso kunye neemfuno zolawulo lwamashishini ziqina ngakumbi nangakumbi, kwaye inani leetheminali liyenyuka ngokuthe ngcembe. Ngophuhliso lweshishini lombane, ukusetyenziswa kweetheminali ngakumbi nangakumbi, kunye neentlobo ezininzi. Terminals ukuququzelela uqhagamshelo iingcingo kunye nezicelo, licandelo itywina kwindawo insulating yeplastiki kumphezulu wegolide, zombini iziphelo zinemingxuma enokufakwa kwiingcingo, kwaye kukho izikrufu zokubopha okanye ukukhulula, ezifana ezimbini. iingcingo, ngamanye amaxesha kufuneka ziqhagamshelwe, ngamanye amaxesha kufuneka ziqhawulwe, ngeli xesha ungasebenzisa iitheminali ukuzidibanisa kwaye zinokuqhawulwa nangaliphi na ixesha, ngaphandle kokuzidibanisa okanye ijijelwe kunye, iluncedo kakhulu kwaye iyakhawuleza.

Nangona kunjalo, ngamanye amaxesha kunokubakho olu hlobo lwetheminali yokukhulula okubangelwa kukuchaswa koqhagamshelwano loluntu kuba kukhulu kakhulu, oko kuvelisa ukufudumeza; iitheminali azikhululekanga, kodwa ngenxa yesekethe ngenxa yezizathu ezithile ezingaziwayo zokusingqongileyo kunye nokufudumeza okugqithisileyo, njengokubonelela ngenkqubo yombane wombane ophezulu kakhulu, okanye umthwalo omfutshane, oya kubangela ukuba i-terminal oxidation ibe mnyama. Ngoko ke, izizathu ze-oxidation kunye neengxaki ze-blackening ze-terminal ziquka ezi ngongoma zimbini zilandelayo.

1.umbane uphezulu kakhulu. Inokuthi ihlolwe ukusuka kumthombo, i-voltage ye-voltage yesibini kwibhokisi yokusabalalisa - i-voltage yesixhobo samandla ngasinye. Iisokethi zinokuba ne-assembly fastening kunye ne-locking fastening. Ukuqiniswa kweNdibano kunokudlala ukuqina okuqinileyo kwibhodi ye-PCB, ukuvala ukutshixa kunokufakwa emva kokugqitywa kokutshixa umama kunye nesokhethi.

Iintlobo ngeentlobo zoyilo lwesokethi ziyafumaneka ukuze zitshatise iindlela ezahlukeneyo zokufakwa kwabasetyhini, njengokuthe tye, ngokuthe nkqo, okanye kwe-engile kwi-PCB. Zombini i-metric kunye neegeyiji zocingo eziqhelekileyo ziyafumaneka.

2. impazamo yomhlaba. Unokujonga kwakhona ukusuka kwi-transformer apho, kwaye emva koko ukuya kwibhokisi yokuhambisa. Isiseko kufuneka sibekwe phantsi, ngelixa iingcingo zesigaba esiqhelekileyo kufuneka zingabandakanywa kwiimpazamo zomhlaba. Inokuthi inikwe amandla ngemitha egqunyiweyo okanye itafile eshukumayo ukulinganisa, kunye nemilinganiselo yecandelo, zama kuphela imilinganiselo yecandelo leentambo, iingcingo, izaphuli zesekethe, iiswitshi, kunye nolunye unikezelo lwamandla kunye nokuhanjiswa kwemigca, kunzima ngokwenene ukwahlula ityala, ikhupha izixhobo ezibuthathaka, izixhobo zokuva, iifusi.

Isitshixo sokumisa umgangatho wokuchasana kufuneka ube phantsi, ngelixa indawo yoqhagamshelwano kufuneka ibe nkulu. Eyangaphambili inokuqinisekisa ukuba indawo yokumisa inokuba kufutshane nesakhono somhlaba esisezantsi kangangoko kunokwenzeka zero, nto leyo enokuthintela ukuba ucinge ngeendudumo, okanye umbane ukusuka kumgca wokumisa ngasemva ukuya, ukubaleka kubonelelo lombane olunokwenzeka. isiphaluka.

Lo mva unokuqinisekisa ukuba kukho umthamo owaneleyo wokubonelela umjelo wangoku ophosakeleyo, kubandakanywa umbane okanye iimpazamo ezimfutshane kunye nokunye. Ngenxa yokuba eyona nkqubo yokwakha isekwe kwithiyori yetekhnoloji yanamhlanje kunye notshintsho lwezobuchwepheshe kunye notshintsho, le ndlela yokumisa inokwenzeka, ilungile okanye imbi, kodwa kwakhona ukubona indlela inkcazo yomgangatho omtsha.

Uqhagamshelwano lweterminal ingozi embi

Izibhengezo kwinkqubo yokufakela, ukuba kukho uxhulumaniso olubi, luya kuchaphazela ukusetyenziswa okuqhelekileyo kwabantu, kwaye kulula ukuba i-oxidize emnyama.

Ufakelo oluchanekileyo kunye nokusetyenziswa kwee-terminals kunokuqinisekisa ukuba ubunjineli bombane ukuphepha ukwenzeka kweempazamo ze-wiring, ngoko ke, ukufakwa kwee-terminals kubaluleke kakhulu. Ukuba kukho ukungabikho kweendlela ezifanelekileyo zobugcisa kwinkqubo yokwakha, ukusebenza ngokufanelekileyo kwee-terminals akuyi kukwazi ukufumana umdlalo opheleleyo. Ngoko ke, ingqalelo kufuneka ihlawulwe kwi-classification ethile yee-terminals, kuba iintlobo ezahlukeneyo zeendlela zokufakela ezihambelanayo zihluke kakhulu. Ngokomzekelo, uhlobo lwe-plug-in kufuneka lufakwe ngokucokisekileyo ukunika umdlalo opheleleyo ekusebenzeni okufanelekileyo. Uhlobo lwebhloko yetheminali kunye nohlobo oluthe kratya, ukufakela kufuneka kusekelwe kwimeko yokwenyani ukukhetha indlela efanelekileyo.

Xa ufaka, kufuneka ukhethe ii-terminals ezinomgangatho ofanelekileyo ukuphepha iingxaki zokhuseleko ezibangelwa yimveliso engafanelekanga. Xa ufaka ii-terminals, kufuneka ukhethe ubungakanani obufanelekileyo bemveliso ngokwemeko yangempela, kwaye usasaze ngokufanelekileyo umthwalo wesigaba sesithathu, kungekhona nje ukuqwalasela uqoqosho lombane, kodwa nokuqonda ukhuseleko lombane. Xa ufaka ibhloko ye-terminal, umphezulu woqhagamshelwano kufuneka ugudiswe ngokufanelekileyo kwaye ugqunywe nge-conductive paste, ukwenzela ukuba ibhloko ye-terminal kunye ne-clip yoqhagamshelwano ekhokelayo ilungile ukuhlangabezana neemfuno zamandla amabini okudibanisa kunye nokusebenza kombane ukunciphisa ithuba lokuvelisa ubushushu. . Indlela yokuba nefuthe kukhuseleko lwemigca enxulumene netheminali, kufuneka ilungiswe ngokukhawuleza. Kufuneka ihlolwe rhoqo ngentambo ekhokelela kumgca wokusabalalisa, ukunciphisa i-peripheral fault factor kunye nemigca yokusasazwa kweengozi zendalo.

Ukuba ibhloko ye-terminal yonakele ekusebenziseni, ayiyi kukwazi ukusetyenziswa kwimveliso yangempela. Ziziphi izizathu zomonakalo? Ukuba ucingo olukhutshiweyo lwebhloko ye-terminal lufutshane kakhulu, indawo ye-spring crimping iya kuba yincinci kakhulu, eya kubangela ngokulula ukuchithwa okucacileyo. Ukuhlutha, akufanele nje ube namava okusebenza okutyebileyo, kodwa kwakhona uxhotyiswe ngesixhobo esikhethekileyo sokuqhawula ukulungisa ubude bokuhlutha. Izitishi zinoluhlu olungqongqo lweemfuno zommandla onqamlezileyo wocingo. Ukuba ayihambelani neemfuno, ii-terminals zocingo aziyi kukwazi ukufakwa ngokupheleleyo kwimingxuma yee-terminals, okubangela ukunciphisa ukuhanjiswa kunye neengxaki ezifihliweyo.

Ubude becrimp kunye nobukhulu bebhloko ye-terminal kufuneka ihlangabezane neemfuno ezifanelekileyo. Xa ucingo luncinci kakhulu, ngenxa ye-insulation phakathi kocingo kunye nommandla woqhagamshelwano kunye nokunyanzeliswa kwexesha elide locingo, ukuqhutyelwa kocingo kuyancipha, ngaloo ndlela kutshisa i-terminals.

Ixesha lokuposa: Feb-05-2024