Kwixesha lanamhlanje elikhula ngokukhawuleza lolwazi lwe-elektroniki, izixhobo zombane ngokungathandabuzekiyo zingamaqabane ayimfuneko kubomi bethu bemihla ngemihla nasemsebenzini. Phakathi kwezinto ezingenakubalwa ezincinci kodwa ezibalulekileyo emva kwazo, iziqhagamshelo ze-elektroniki zibaluleke kakhulu. Benza imisebenzi ebalulekileyo yokudibanisa, kunye nokudlulisa imiqondiso kunye namandla, ukuqinisekisa ukuba izixhobo zethu zonxibelelwano, iinkqubo zekhompyutha, kunye nezixhobo ezahlukeneyo ezihlakaniphile zinokusebenza kakuhle.

1. Kutheni ukhetha igolide yokubeka?

Iinjineli ze-elektroniki zinokuthi ziqaphele ukuba ezininzi iziqhagamshelo eziphezulu zisebenzisa iingubo ezikhethekileyo zetsimbi, apho igolide (igolide) i-plating ixhaphake kakhulu. Oku akubangelwa bubunewunewu begolide, kodwa ngenxa yokuba igolide ine-conductivity egqwesileyo yombane kunye nokumelana ne-oxidation, enokuphucula kakhulu ukusebenza kunye nokuthembeka kwekhonkco.

Amandla omatshini kunye nokuqina

Izixhumi ze-elektroniki zingena ngokuphindaphindiweyo kunye nokukhupha i-pluging ekusetyenzisweni kwansuku zonke, okudinga ukuba iindawo zabo zoqhagamshelwano zibe neqondo eliphezulu lamandla omatshini kunye nokuqina. Ngokutyalwa kwegolide, ukuqina kunye nokumelana nokunxiba kweendawo zoqhagamshelwano kuyaphuculwa, kwaye i-ductility kunye ne-friction coefficient nayo iphuculwe, iqinisekisa ukuba isinxibelelanisi sinokugcina ukusebenza kakuhle koqhagamshelwano naphantsi kokusebenza rhoqo.

Ukukhuselwa kokubola kunye nokuzinza

Amacandelo angundoqo amaninzi okudibanisa umbane ayenziwe ngama-alloys obhedu, axhomekeke kwi-oxidation kunye ne-vulcanization kwiindawo ezithile. I-Gold plating inokubonelela ngomqobo wokunqanda ukubola kwizihlanganisi, ukwandisa ubomi babo benkonzo kwiindawo ezinzima. Ukongeza, igolide izinzile ngokwekhemikhali kwaye ayisebenzi ngokulula kunye nezinye izinto, ngaloo ndlela ikhusela amacandelo esinyithi angaphakathi kwikhonkco kwi-corrosion.

2. Ukusungula izinto ezintsha zobugcisaibhodi-to-ibhodi izihlanganisi

Kuyilo lweebhodi zeesekethe ezidityanisiweyo eziphezulu, iibhodi zebhodi ukuya kwibhodi ezidibanisayo zidlala indima ebalulekileyo. Abafuni nje ukuthwala imisinga enamandla, kodwa kufuneka bagcine iimpawu zihanjiswa ngokucacileyo. Ngesi sizathu, iziqhagamshelo zebhodi ukuya kwibhodi zanamhlanje zisebenzisa itekhnoloji yeplating ephucukileyo kunye nezixhobo zokusebenza eziphezulu.

Ukuguquguquka kwesithuba esincinci

Njengoko ubukhulu bezixhobo buqhubeka bucutheka, i-pitch ye-connectors nayo ifuna ukuncitshiswa ngokufanelekileyo. Okwangoku, iziqhagamshelo zebhodi ukuya ebhodini eziphambili zinokufikelela kuyilo lwepitch entle ye-0.15mm ukuya kwi-0.4mm ukuhlangabezana neemfuno zezixhobo zombane ezincinci.

Ugqithiso oluphezulu lwangoku

Nokuba ngaphakathi kobukhulu obuncinci, ezi ziqhagamshelo zinokusasaza ngokukhuselekileyo imisinga emikhulu ye-1-50A ngokuzinza okunamandla okungaphaya, ukuhlangabezana neemfuno ezingqongqo zobonelelo lwamandla kwizixhobo zanamhlanje zombane.

Ubomi benkonzo ende ixesha elide

Isidibanisi esicwangciswe ngokucokisekileyo kunye negolide sinobomi benkonzo engaphezulu kwe-200,000 yokuxhuma kunye nokukhupha amaxesha, okuphucula kakhulu ukuthembeka kwemveliso kunye nokusebenza kakuhle kovavanyo.

Imithombo ye-POGOPIN yenziwe ngobhedu lweberyllium, intsimbi engatyiwa, kunye nocingo lwepiyano. Isixhobo ngasinye sineempawu ezizodwa. Kwintsimi yoyilo lwentwasahlobo, kukho izinto ezisisiseko zokuqwalaselwa: ubushushu bokusebenza, i-impedance, kunye neemfuno ze-elasticity. Umthombo unesilivere. I-electroplated ukuze iqhube kakuhle. Igolide ibonelela nge-conductivity yombane engcono kunye neempawu eziphezulu ze-thermal, kunye nokukhuselwa kwi-oxidation kunye ne-corrosion.

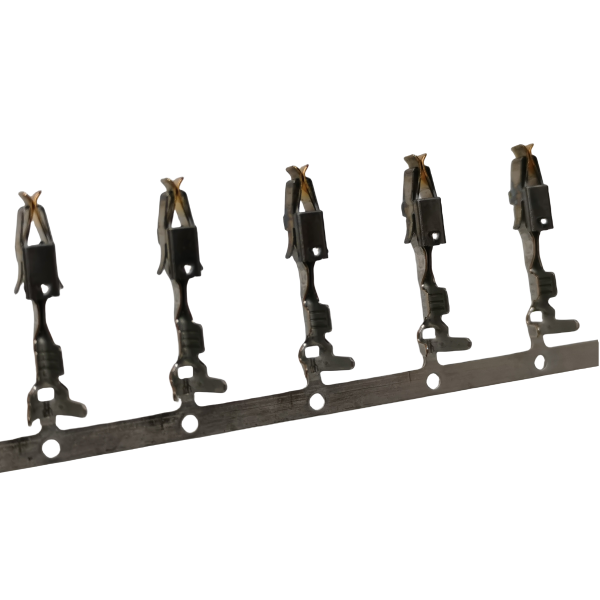

2-929939-1:TE isinxibelelanisi-itheminali enegolide

Shwankathela:

Kweli xesha lophuhliso olukhawulezayo lwetekhnoloji yolwazi, ukubaluleka kweziqhagamshelo ze-elektroniki njengamacandelo asisiseko kuye kwavela ngakumbi. Ngokufaka iplating yegolide yobugcisa obuphezulu kwezi ziqhagamshelo, asiphuculi nje ukusebenza kwazo kodwa sikwabonelela ngenkxaso eyomeleleyo yezixhobo zombane ezahlukeneyo. Ngokuhambela phambili kwetekhnoloji, abaqhagamshelo bexesha elizayo baya kuba bancinci kwaye babe nobukrelekrele ukuhlangabezana neemfuno ezikhulayo zonxibelelwano kunye nokuhlanganiswa kobuchwepheshe obuvelayo.

Ixesha lokuposa: Apr-19-2024