Intshayelelo kwiziqhagamshelo zePCB:

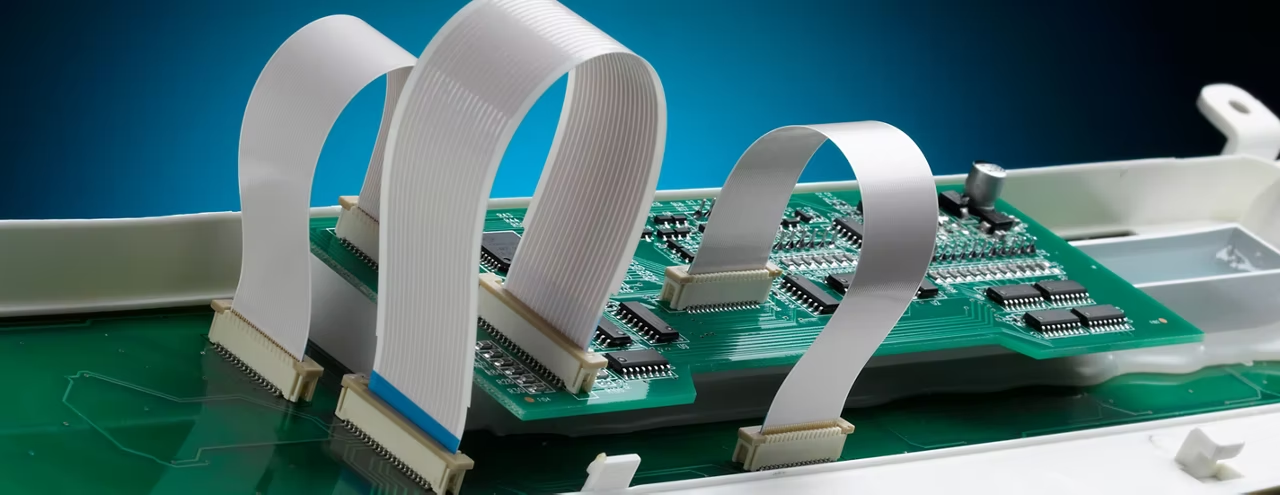

Ibhodi yesekethe eprintiweyo (PCB) izihlanganisilelinye lawona malungu abalulekileyo kwiimveliso ze-elektroniki eziqhagamshela uthungelwano olunzima loqhagamshelwano. Xa isinxibelelanisi sinyuselwe kwibhodi yesekethe eprintiweyo, iPCB isidibanisi sezindlu sibonelela ngesixhobo somdibaniso. Izihlanganisi ze-PCB zisetyenziselwa ukudibanisa iibhodi zesekethe eziprintiweyo ezahlukeneyo ukuya kwenye okanye ukuvumela iintambo ukuba ziqhagamshelwe kwi-PCB.

Ukusuka kwii-electronics zabathengi ezifana nee-smartphones kunye neelaptops kwiinkqubo ezibalulekileyo kwi-aerospace kunye nezixhobo zonyango, ukwahlukana kwezicelo ze-PCB zisebenza kuwo wonke amashishini, okuvumela izixhobo ukuba zinxibelelane ngendlela ethembekileyo nesebenzayo.

Eli nqaku liza kujonga nzulu ukuba iPCB encinci kodwa inamandla kangakanani na ibhulorho ebambe i-ecosystem yethu ye-elektroniki kunye malunga nezihlanganisi zePCB.

Iinkcukacha zobugcisa kunye neemfuno zokusebenza:

Umsebenzi wokudibanisa unokubonakala ulula (ukudibanisa icandelo elinye kwelinye), kodwa ngaphantsi kwendawo kukho ukudibanisa okuyinkimbinkimbi yezinto zombane, oomatshini kunye nokusingqongileyo.

I-voltage elinganisiweyo yangoku kunye nemilinganiselo ebalulekileyo kwintsebenzo yombane, ukugqiba amandla aphezulu ukuba ikhonkco inokusingatha ngaphandle kokutshisa okanye umonakalo - emva koko, into yokugqibela ofuna ukuba yenzeke kukuba ingaphumeleli xa ifuneka ekusebenzeni ngokufanelekileyo.

Izixhumi ziyakwazi ukumelana nokufakwa kunye nokususwa, ukungcangcazela, okanye ukuya kweminye imisebenzi, ngelixa uxhulumaniso lwecandelo eliqhubekayo, ukuqhawulwa kwendalo ukuqinisekisa ukuba ukuqina koqhagamshelwano, ukwenzela ukuba kufezekiswe ukuthembeka komatshini.

Ukususela kumaqondo obushushu agqithisileyo kunye namanqanaba okufuma ukuya eluthulini nasekukhuselweni kolwelo, i-IP (i-Ingress Protection) kunye nezinye izilinganiso zokusingqongileyo kwisakhono sokukhusela isinxibelelanisi kwiimeko zangaphandle zivavanywa ukuze kuqinisekiswe ukuba ukukwazi ukusebenza kwiindawo eziphakamileyo kunokuba yinto eqhelekileyo kwaye engachaphazelekanga.

Ukuqinisekisa uxhulumaniso oluthembekileyo ngokuhamba kwexesha, kubalulekile ukubetha ibhalansi elungileyo phakathi kokuqina nokusebenza kakuhle. Ukufakwa kwegolide kwiindawo zoqhagamshelwano kuthintela i-oxidation. I-alloy yobhedu esetyenziselwa umzimba kunye noqhagamshelwano lulinganisa amandla kunye ne-conductivity, igalelo ekusebenzeni ngokufanelekileyo kwekhonkco.

Uzibona njani (ukhetha) izihlanganisi zePCB?

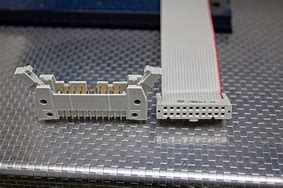

Ukuqaphela okanye ukukhetha izihlanganisi zePCB, qala ujonge imilo, ubungakanani, inani lezikhonkwane, kunye nolungiselelo lweempawu.

Oku kuya kunceda ukumisela uhlobo lokudibanisa. Okwesibini, qwalasela uhlobo lwephini lokuqhagamshela (umz. izikhonkwane, iisokethi, iipadi, njl.njl.) kunye nolungiselelo, kunye nohlobo lojongano (njengohlobo lwe-D, i-USB, i-HDMI, njl.). Okokugqibela, khangela ilogo kunye nenombolo kwiPCB isidibanisi ukumisela uhlobo yayo.

Cacisa iimfuno zesicelo somdibanisi. Qwalasela izixhobo zombane, iisistim, okanye usetyenziso oluza kusebenzisa isiqhagamshelo, kunye nesangoku, ivoltheji, kunye nohlobo lwesiginali ekufuneka isihlanganisi siluthwale.

Qwalasela imiqobo yendawo yebhodi kunye neemfuno zoyilo. Khetha isayizi yesihlanganisi esifanelekileyo, imilo, kunye nenani lezikhonkwane ezisekelwe kubungakanani bebhodi, uyilo, kunye nesithuba phakathi kwamalungu. Qinisekisa ukuba umdibaniso unokulungiswa kwiimfuno zoyilo lwebhodi.

Ukuthembeka kunye nokuqina kwekhonkco kubalulekile ekusebenzeni okuzinzile kwexesha elide. Izixhumi ezinomgangatho wezinto ezilungileyo kunye neenkqubo zokuvelisa ezinokumelana nokutshintsha kobushushu, ukungcangcazela, ukothuka, kunye neekhemikhali kufuneka zikhethwe.

Iiparamitha ezinjengobomi beplagi kunye nokuchasana koqhagamshelwano lwekhonkco kufuneka kuthathelwe ingqalelo. Ukongezelela, kubalulekile ukuqwalasela iimeko zokusingqongileyo apho isinxibelelanisi siya kuboniswa khona. Khetha izihlanganisi ezineempawu ezifanelekileyo zokungangeni manzi, uthuli, kunye nokumelana nokutyiwa okusekwe kwiimeko zokusingqongileyo, ezinje ngeqondo lobushushu, ukufuma, nokuchanabeka kwizinto ezidlayo kunye nothuli.

Qwalasela iimfuno zofakelo kunye nokugcinwa kwekhonkco, kwaye ukhethe izihlanganisi ekulula ukuzifaka, ukuplaga, kunye nokugcina ukunciphisa ixesha kunye neendleko zenkqubo yokuvelisa kunye nokugcinwa.

Qwalasela iimfuno zofakelo kunye nokugcinwa kwekhonkco, kwaye ukhethe izihlanganisi ekulula ukuzifaka, ukuplaga, kunye nokugcina ukunciphisa ixesha kunye neendleko zenkqubo yokuvelisa kunye nokugcinwa. Ukuqinisekisa ukusebenza kakuhle kweendleko ngokukhetha izihlanganisi ezihlangabezana neemfuno ngaphandle kokugqithisa uhlahlo lwabiwo-mali.

Indlela yokudibanisa iibhodi zePCB?

I-Soldering yindlela eqhelekileyo yokudibanisa iibhodi zePCB. Kubandakanya ukusebenzisa izixhobo ze-solder kunye ne-soldering ukudibanisa i-electronic component pins kwiipads kwibhodi ye-PCB. Oku kubonelela ngoqhagamshelo lombane oluthembekileyo kunye namandla oomatshini kuninzi lwezixhobo zombane.

Iziqhagamshelo zeplagi kwelinye icala zifakwe kwiindawo zokubeka ikhonkco kwibhodi yePCB kusetyenziswa izikhonkwane okanye iisokethi. Le ndlela ivumela ukuxhuma ngokukhawuleza kunye nokukhupha ibhodi kwezinye iimodyuli okanye izixhobo, okwenza ukuba zilungele izicelo ezifuna ukutshintshwa rhoqo okanye ukulungiswa.

Izixhumi zoqhagamshelwano zasentwasahlobo, ezisebenzisa uqhagamshelwano lwasentwasahlobo ukudibanisa kwiipads okanye kwiindawo zokubeka kwi-PCB, zidla ngokusetyenziswa kwizicelo ezifuna ukuhanjiswa kwedatha yesantya esiphezulu okanye ukuxhuma rhoqo kunye nokukhupha, njengezixhobo zokunxibelelana ngesantya esiphezulu okanye izixhobo zokuvavanya.

Iibhloko ze-terminal PCB: Iibhloko ze-terminal PCB zizihlanganisi ezisetyenziselwa ukuncamathisela iingcingo okanye zikhokelela kwibhodi yesekethe ye-PCB. Zikhuselwe nge-screwing okanye i-crimping ukuqinisekisa uqhagamshelo lombane oluthembekileyo.

Ikamva leziQhagamshelwano ze-PCB: i-Innovation kunye noPhuhliso:

Uphuhliso lweziqhagamshelo zePCB luza kugxila ekuphuculeni ubungakanani obuncinci, ukuxinana okuphezulu, ukuhanjiswa kwesantya esiphezulu, ukuthembeka, ukuzenzela, ukukhuselwa kokusingqongileyo, kunye nonxibelelwano olungenazingcingo. Olu tshintsho luya kuphucula ukusebenza kunye nokusebenza kwezixhobo ze-elektroniki ukuhlangabezana nemfuno ekhulayo yemarike.

Injongo kukufezekisa ubungakanani obuncinci kunye nokuxinana okuphezulu. Izixhobo zombane ziya zisiba ncinci kwaye zikhaphukhaphu, kwaye ngenxa yoko, iziqhagamshelo zePCB nazo ziya zincinci kwaye zipakishwe kakhulu. Ubuncinci, ubuninzi obuphezulu, kunye nezixhumi zebhodi yesekethe eziguquguqukayo ngoku zisetyenziswa ngokuqhelekileyo kwiimveliso ezincinci ezifana neeselfowuni, iiPC zethebhulethi, kunye nezixhobo ezinxitywayo.

Ezi ziqhagamshelo zilungele ukuhanjiswa kwesantya esiphezulu kunye nezicelo ze-frequency ephezulu. Ngenxa yesidingo esikhulayo sonxibelelwano kunye nokuhanjiswa kwedatha, izihlanganisi ze-PCB kufuneka zixhase amazinga aphezulu othumelo lwedatha kunye namaza. Iziqhagamshelo zesantya esiphezulu esinesantya esiphezulu, ezinje nge-USB Type-C kunye neThunderbolt, kunye neziqhagamshelo zeRF ezinjengeziqhagamshelo ze-eriyali, zihlala zisetyenziswa.

Izihlanganisi ze-PCB zifuna ukuthembeka okuphezulu kunye nokuqina ukumelana neendawo zokusebenza ezintsonkothileyo kunye nokuqhagamshelwa rhoqo kunye nokuqhawulwa. Oku kunokufezekiswa ngokusebenzisa izinto ezingaphezulu zokunxiba, ukomeleza uyilo lwamanqaku oqhagamshelwano, kunye nokusetyenziswa kweteknoloji yoqhagamshelo ethembekileyo.

Ukongeza, i-automation kunye nobukrelekrele bunokuphunyezwa. Ishishini lemveliso lingqina ukunyuka kwe-automation kunye nobukrelekrele, kwaye izihlanganisi zePCB zilandela. Ngoku beza bexhotyiswe ngokufakela kunye neendlela zokususa ngokuzenzekelayo, imisebenzi yokufumanisa kunye nokugcinwa, ukuhanjiswa kwedatha, kunye nokukwazi ukunxibelelana.

Kukho ugxininiso olukhulayo ekukhuselweni kwendalo kunye nokuzinza. Ukwenziwa kunye nokusetyenziswa kwezihlanganisi ze-PCB kuya kugxila ngakumbi kubuhlobo bendalo ngenxa yendlela yokukhusela nokuzinzileyo. Oku kubandakanya ukusetyenziswa kwezinto ezinokuphinda zisetyenziswe, iinkqubo zokuvelisa amandla aphantsi, kunye noyilo lwesixhumi esisuswayo.

Ixesha lokuposa: Mar-21-2024