Izixhumi zetheminali yezimotoemkhakheni wezintambo zezintambo zezimoto ziyingxenye ebalulekile yensimu, kodwa futhi zinqume ngokuqondile isignali yesixhumi kanye nokudluliswa kwamandla kwama-node abalulekile. Ngokuthuthuka okusheshayo kwemboni yezimoto yaseChina, ukuthuthukiswa okuqhubekayo komkhakha wezingxenye zezimoto nakho kukhuthaza isixhumi sezimoto ekuthuthukisweni okucwengisiswe kakhulu nokuthembekile.

Ngokubuyekeza izinkinga ezidlule ekusetshenzisweni kwamatheminali okuxhuma, sithole ukuthi izici ezilandelayo zizothinta ikhono lokudlulisa amatheminali: izinto zokwakha, ukwakheka kwedizayini, ikhwalithi yendawo ephezulu, kanye ne-crimping.

Impahla yetheminali

Ngokucabangela ukusebenza nomnotho, imboni yokuxhuma yasekhaya ngokuvamile isebenzisa izinto ezimbili: ithusi nethusi. I-Brass ivamise ukuhambisana nokuhle, kodwa ithusi elivumelana nezimo. Uma kubhekwa amatheminali epulaki nesokhethi esakhiweni somehluko, ngokuvamile beka kuqala ukusetshenziswa kwamatheminali epulaki kunethusi eliqhuba kakhulu. Amatheminali esokhethi ngokwawo ngokuvamile anomklamo oguquguqukayo, kucatshangelwa izidingo ze-conductivity, futhi ngokuvamile akhetha izinto zethusi ukuqinisekisa ukwethembeka kwe-shrapnel yokugcina.

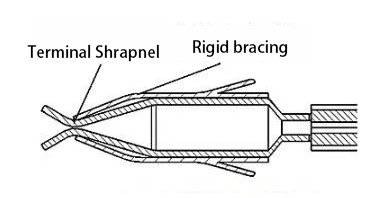

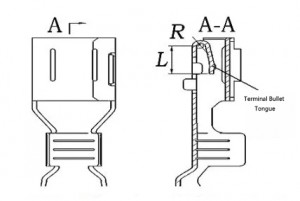

Ngezidingo eziqinile ze-conductivity yamatheminali esokhethi, ngenxa ye-conductivity yento yethusi engakwazi ukuhlangabezana nezidingo, umkhuba ojwayelekile ukukhetha izinto zokugcina isokhethi zethusi, kucatshangelwa ukukhubazeka kwezinto zethusi ngokwazo aziguquguquki kancane, ukunwebeka kuzoncipha. Esakhiweni ukwandisa isakhiwo sokusekela esiqinile ukuze kwandiswe ukunwebeka kwamatheminali. Njengoba kukhonjisiwe kuMfanekiso (1).

Umfanekiso 1 Umdwebo wesakhiwo setheminali yesokhethi enokwesekwa okuqinile

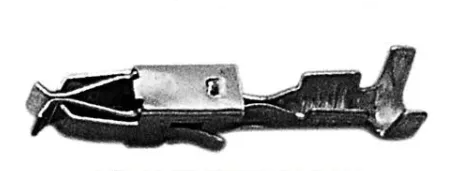

Encazelweni engenhla yesakhiwo setheminali esinokusekelwa okuqinile kuMfanekiso (2), isakhiwo sokusekela esiqinile sithuthukisa ukucindezelwa okuhle kwe-conductive laminating surface, ngaleyo ndlela kuthuthukise ukwethembeka komkhiqizo.

Umfanekiso 2 Isithombe setheminali yesokhethi enokwesekwa okuqinile

Umklamo wesakhiwo

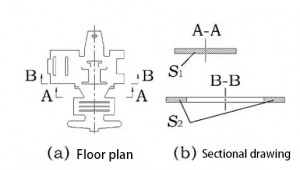

Empeleni, ukwakheka komklamo kuwumthombo ovulekile wokunciphisa izindleko zezinto ezingavuthiwe, kuyilapho kugcinwa ukudluliswa kwamandla kwamatheminali. Ngakho-ke, amatheminali okuxhuma asengozini kakhulu kumthelela wokudluliswa kwamandla njengengxenye yesakhiwo sazo “sebhodlela,” okubhekiselwa kumatheminali endaweni yokuqhuba yengxenye encane yesiphambano sesakhiwo. Njengoba kuboniswe kuMfanekiso (3), isakhiwo sithinta ngokuqondile umthamo wamanje wokuthwala wetheminali.

Umfanekiso 3 Umdwebo wohlelo lokunwetshwa kwetheminali

Umfanekiso 3b ubonisa ukuthi indawo ye-cross-sectional ye-S1 inkulu kune-S2, ngakho-ke ingxenye ephambanayo ye-BB isesimweni sebhodlela. Lokhu kubonisa ukuthi, ohlelweni lokuklama, isigaba esiphambanayo kufanele sihlangabezane nezidingo zokuqhuba zetheminali.

I-surface plating

Ezixhunyweni eziningi, i-tin plating iyindlela evamile yokuhlanganisa. Ububi be-tin plating buhlanganisa lokhu okubili okulandelayo: okokuqala, ukufakwa kwe-tin kuzoholela ekunciphiseni ukuthengiswa kwe-solderability kanye nokwanda kokumelana nokuxhumana, okubangelwa ikakhulukazi ekuvikelweni kwensimbi kanye nensimbi phakathi kwensimbi. Okwesibili, into yokuxhumana ehlanganisiwe inokungqubuzana okuphezulu kwendawo uma kuqhathaniswa nensimbi ecwecwe, okuholela ekwandeni kwamandla okufakwa kwesixhumi, ikakhulukazi kuzixhumi zezintambo eziningi.

Ngakho-ke, ekufakweni kwezixhumi ze-multiwire, izinqubo ezintsha zokucwenga zisetshenziswa lapho kunokwenzeka khona ukuze kuqinisekiswe ukudluliswa koxhumano ngenkathi kunciphisa ukufakwa kwamanje. Isibonelo, ukufakwa kwegolide kuyindlela enhle yokucwenga.

Kusukela endaweni yokubuka ye-micro-physical, noma iyiphi indawo ebushelelezi inobuso obumangelengele futhi obungalingani, ngakho-ke ukuthintana kwamatheminali kuwukuthintana kwephuzu kunokuxhumana okungaphezulu. Ukwengeza, izindawo eziningi zensimbi zimbozwe i-non-conductive oxide nezinye izinhlobo zezendlalelo zefilimu, ngakho-ke ngomqondo wangempela wezindawo zokuthintana zikagesi - ezibizwa ngokuthi “ama-conductive spots - kungenzeka yini ukuthintana ngogesi.

Njengoba iningi labathintwayo kungokuthintwa kwefilimu, lapho i-current idlula ezingxenyeni ezimbili zokuthintana zesixhumi esibonakalayo, izogxila kulezo zindawo ezincane kakhulu zokuqhuba.

Ngakho-ke, eduze nezindawo eziqhutshwayo zomugqa wamanje zizovunyelwa, okuholela ekwandeni kobude bomzila wokugeleza kwamanje, futhi indawo yokuhambisa ephumelelayo iyancishiswa. Lokhu kumelana kwendawo kubizwa ngokuthi "ukumelana nokuncipha" futhi kuthuthukisa ukuqedwa kwendawo kanye nezakhiwo zokudlulisela zamatheminali.

Njengamanje, kunemibandela emibili yokuhlola ikhwalithi yokucwenga: okokuqala, ukuhlola ukujiya kocwecwe. Le ndlela ihlola izinga le-coating ngokulinganisa ukushuba kwe-coating. Okwesibili, izinga le-plating lihlolwa kusetshenziswa ukuhlolwa kwesifutho sikasawoti esifanele.

Ukucindezela okuhle kwe-shrapnel yokugcina

Ukucindezela okuqondile kwesixhumi kuyinkomba ebalulekile yokusebenza kwesixhumi, okuthinta ngqo amandla okufaka isiphetho kanye nezakhiwo zikagesi. Kubhekiselwa kutheminali yepulaki yesixhumi kanye nesokhethi yetheminali yokuxhumana ehambisana ne-perpendicular force surface yokuxhumana.

Ekusetshenzisweni kwamatheminali, inkinga evame kakhulu amandla okufaka phakathi kwetheminali kanye nesilawuli setheminali azinzile. Lokhu kungenxa yokucindezela okuhle okungazinzile ku-shrapnel yokugcina, okuholela ekwandeni kokumelana kwendawo yokuxhumana yetheminali. Lokhu kuholela ekwenyukeni kwezinga lokushisa lamatheminali, okuholela ekushisweni kwesixhumi nokulahlekelwa yi-conductivity, noma ngisho nasezimweni ezimbi kakhulu, ukutubeka.

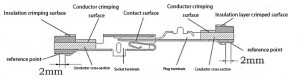

Ngokusho kwe-QC/T417 [1], ukumelana nokuxhumana kuwukumelana phakathi kwezindawo zokuxhumana zesixhumi futhi kufaka phakathi izici ezilandelayo: ukumelana kwangaphakathi kwamatheminali, ukumelana okubangelwa ukucwiliswa kwamakhondakta, ukumelana nocingo. endaweni yereferensi, kanye nokumelana kwe-shrapnel yepulaki kanye namatheminali e-socket othintana naye (Fig. 4).

Izinto zetheminali zithinta kakhulu ukumelana kwangaphakathi, ikhwalithi yokucwiliswa komkhiqizo ithinta ukumelana okukhiqizwa i-conductor crimp, i-plug terminal kanye ne-socket terminal shrapnel ngokuthinta ukumelana okukhiqizwa yizici ze-conductive ze-terminal, kanye nokukhuphuka kwezinga lokushisa kwe-terminal. inani lomthelela omkhulu. Ngakho-ke, ekwakhiweni kokucatshangelwa okubalulekile.

Umfanekiso4 Umdwebo wohlelo lokumelana nokuxhumana

Ukucindezela okuhle kutheminali kuncike ekunwebeni kokuphela kolimi lwenhlamvu. Irediyasi egobayo R kanye nobude be-cantilever L bolimi bunomthelela oqondile kuleli nani futhi kufanele kucatshangelwe phakathi nenqubo yokuklama. Ukwakheka kwe-shrapnel yetheminali kuboniswe kuMfanekiso 5.

Umfanekiso 5 Umdwebo wohlelo lwesakhiwo se-shrapnel esibulalayo

Umsila crimping

Izinga lokudluliswa kwetheminali lithintwa ngokuqondile ikhwalithi yokuma kwetheminali. Ubude bokuzibandakanya nobude be-crimp kunomthelela omkhulu kwikhwalithi ye-crimp. I-crimp eqinile inamandla angcono wemishini kanye nezakhiwo zikagesi, ngakho-ke ubukhulu besigaba se-crimp kufanele ilawulwe ngokuqinile. Ububanzi bocingo buyisici esibalulekile esithonya umphumela we-crimping phakathi kwetheminali nocingo.

Ngaphezu kwalokho, ucingo ngokwalo lufanelekile ukutadisha, ngoba imikhiqizo yasekhaya neyangaphandle inezici zayo eziyingqayizivele. Ekukhiqizeni kwangempela, izimiso ezilandelayo kufanele zibhekwe: ububanzi bocingo kufanele bufaniswe nokuphela kwetheminali, ubude bengxenye yekhanda kufanele bulinganiselwe, futhi isikhunta esifanele se-crimping, crimping ngemva kokuhlolwa kwe-Rattori.

Hlola izindlela zetheminali crimping okuhlanganisa ukuhlola iphrofayili yetheminali yokugoqa kanye namandla okudonsa. Ngokubheka iphrofayili, ungahlola imiphumela ye-crimping ukuze uqiniseke ukuthi azikho iziphambeko ezifana nezintambo zethusi ezilahlekile noma ukuphuma phansi. Ngaphezu kwalokho, amandla okudonsa ahlola ukwethembeka kwe-crimp.

Isikhathi sokuthumela: Jul-18-2024