Enkathini yanamuhla yolwazi lwe-elekthronikhi ethuthukayo ngokushesha, izinto zikagesi ngokungangabazeki zingozakwethu ababalulekile ezimpilweni zethu zansuku zonke nasemsebenzini. Phakathi kwezingxenye ezincane ezingenakubalwa kodwa ezibalulekile ezingemuva kwazo, izixhumi zikagesi zibaluleke kakhulu. Benza imisebenzi ebalulekile yokuxhuma, nokudlulisa amasignali namandla, ukuqinisekisa ukuthi izinto zethu zokuxhumana, izinhlelo zamakhompiyutha, kanye namadivayisi ahlakaniphile ahlukahlukene angasebenza kahle.

1. Kungani ukhetha ukufakwa kwegolide?

Kungenzeka ukuthi onjiniyela be-elekthronikhi baye baqaphela ukuthi izixhumi eziningi ezisebenza kahle kakhulu zisebenzisa izimbotshana zensimbi ezikhethekile, lapho ukucwecwa kwegolide (igolide) kuvame kakhulu. Lokhu akubangelwa ukunethezeka kwegolide, kodwa ngenxa yokuthi igolide line-conductivity kagesi enhle kakhulu kanye nokumelana ne-oxidation, okungathuthukisa kakhulu ukusebenza nokuthembeka kwesixhumi.

Amandla omshini nokuqina

Izixhumi zama-elekthronikhi zixhunywa ngokuphindaphindiwe futhi zinqanyulwe ekusetshenzisweni kwansuku zonke, okudinga ukuthi izindawo zazo zokuxhumana zibe nezinga eliphezulu lamandla emishini nokuqina. Ngokucwecwa kwegolide, ukuqina nokumelana nokugqokwa kwamaphoyinti okuxhumana kuyathuthukiswa, futhi i-ductility ne-coefficient yokungqubuzana nayo iyathuthukiswa, kuqinisekiswe ukuthi isixhumi singakwazi ukugcina ukusebenza kahle kokuxhumana ngisho nangaphansi kokusebenza kaningi.

Ukuvikela ukugqwala nokuzinza

Izingxenye eziyinhloko zezixhumi zikagesi eziningi zenziwe ngama-alloys ethusi, ajwayele uku-oxidation kanye ne-vulcanization ezindaweni ezithile. Ukufakwa kwegolide kunganikeza isithiyo sokunqanda ukugqwala kwezixhumi, kunwebe impilo yazo yesevisi ezindaweni ezinokhahlo. Ngaphezu kwalokho, igolide lizinzile kumakhemikhali futhi alisabelani kalula nezinye izinto, ngaleyo ndlela livikela izingxenye zensimbi zangaphakathi zesixhumi ekugqwaleni.

I-AmphenolI-MS10A23F:Gold Plated Socket Contact

2. Ukuqamba okusha kwezobuchwephesheizixhumi zebhodi kuya ebhodini

Ekwakheni amabhodi esekethe adidiyelwe aphezulu, izixhumi zebhodi kuya ebhodini zidlala indima ebalulekile. Akudingeki nje ukuthi baphathe imisinga enamandla, kodwa futhi badinga ukugcina amasignali asakazwa ngokucacile. Ngenxa yalesi sizathu, izixhumi zesimanje zebhodi ukuya ebhodini zisebenzisa ubuchwepheshe bokucwenga obuyinkimbinkimbi kanye nezinto ezisebenza kahle kakhulu.

Ukuguquguquka kwesikhala esincane

Njengoba usayizi wamadivayisi uqhubeka nokuncipha, ukuphakama kwezixhumi nakho kudinga ukuncishiswa ngokufanele. Njengamanje, izixhumi ezithuthukisiwe zebhodi ukuya ebhodini zingafinyelela imiklamo emihle ye-pitch engu-0.15mm ukuya ku-0.4mm ukuze kuhlangatshezwane nezidingo zemishini ye-elekthronikhi encane.

Amandla okudlulisa aphezulu wamanje

Ngisho nangaphakathi kosayizi omncane, lezi zixhumi zingadlulisela ngokuphephile amaza amakhulu angu-1-50A ngokuzinza okunamandla okudlulele, okuhlangabezana nezidingo eziqinile zokuphakelwa kwamandla kwemishini yesimanje kagesi.

Impilo yesevisi ende eyengeziwe

Isixhumi esiklanywe ngokucophelela nesigqitshwe ngegolide sinempilo yesevisi yezikhathi ezingaphezu kuka-200,000 zokuxhuma nokukhipha i-plug, okuthuthukisa kakhulu ukuthembeka komkhiqizo nokusebenza kahle kokuhlola.

Imithombo ye-POGOPIN yenziwe ngethusi le-beryllium, insimbi engagqwali, nocingo lwepiyano. Impahla ngayinye inezici zayo ezihlukile. Emkhakheni wokuklama kwentwasahlobo, kukhona okucatshangelwayo okuyisisekelo: izinga lokushisa lokusebenza, i-impedance, nezidingo zokunwebeka. Isiphethu sinombala osiliva. I-electroplated ukuze ibe ngcono. Igolide lihlinzeka nge-conductivity kagesi engcono kanye nezakhiwo ezishisayo eziphezulu, kanye nokuvikelwa ngokumelene ne-oxidation nokugqwala.

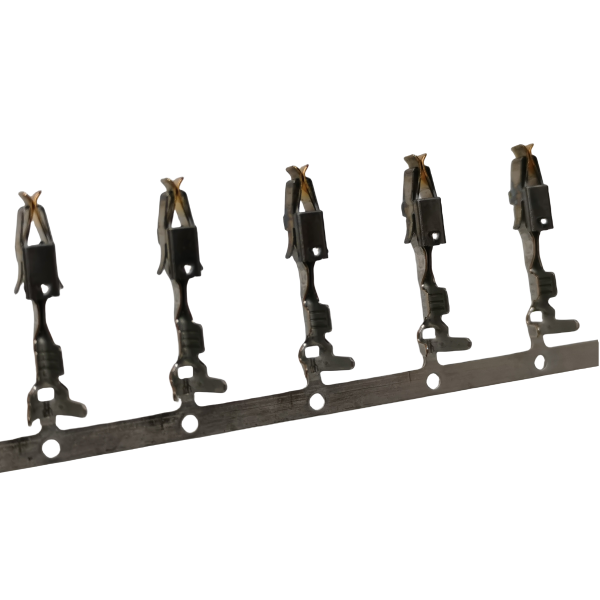

2-929939-1:Isixhumi se-TE-itheminali egcwele igolide

Fingqa:

Kule nkathi yokuthuthukiswa okusheshayo kobuchwepheshe bolwazi, ukubaluleka kwezixhumi ze-elekthronikhi njengezingxenye eziyisisekelo sekuvele kwagqama kakhulu. Ngokusebenzisa i-high-tech plating yegolide kulezi zixhumi, asigcini nje ngokuthuthukisa ukusebenza kwazo kodwa futhi sinikeza ukusekela okuqinile kwemishini ehlukahlukene kagesi. Ngokuthuthuka kobuchwepheshe, izixhumi zesikhathi esizayo zizokwenziwa zibe mincane futhi zihlakaniphe ukuze zihlangabezane nezidingo ezikhulayo zokuxhumana kanye nokuhlanganiswa kobuchwepheshe obusafufusa.

Isikhathi sokuthumela: Apr-19-2024