Isingeniso kuzixhumi ze-PCB:

Izixhumi zebhodi lesifunda eliphrintiwe (PCB).zingenye yezingxenye ezibaluleke kakhulu zemikhiqizo ye-elekthronikhi exhuma amanethiwekhi ayinkimbinkimbi okuxhumana. Uma isixhumi sigxunyekwe ebhodini lesekethe eliphrintiwe, indlu yesixhumi se-PCB inikeza isitsha sokwamukela isixhumi. Izixhumi ze-PCB zisetshenziselwa ukuxhuma amabhodi esekethe ahlukene aphrintiwe komunye nomunye noma ukuvumela izintambo ukuthi zixhunywe ku-PCB.

Kusukela kuma-electronics abathengi njengama-smartphones namakhompyutha aphathekayo kuya kumasistimu abalulekile ku-aerospace namadivayisi ezokwelapha, ukuhlukahluka kwezinhlelo zokusebenza ze-PCB kusebenza kuzo zonke izimboni, okuvumela amadivayisi ukuthi axhumane ngendlela ethembekile nephumelelayo.

Lesi sihloko sizobheka kabanzi ukuthi izingxenye ze-PCB ezincane kodwa ezinamandla zingaba kanjani ngempela ibhuloho elibamba i-electronic ecosystem yethu ndawonye ezizungeze izixhumi ze-PCB.

Ukucaciswa kobuchwepheshe nezimfuneko zokusebenza:

Umsebenzi wesixhumi ungase ubonakale ulula (ukuxhuma ingxenye eyodwa kwenye), kodwa ngaphansi kobuso kukhona ukuxhumana okuyinkimbinkimbi kwezici zikagesi, zemishini nezemvelo.

I-voltage elinganiselwe yamanje nekaliwe yizici ezibalulekile ekusebenzeni kukagesi, okunquma amandla aphezulu isixhumi esingawaphatha ngaphandle kokushisa ngokweqile noma ukulimala - emva kwakho konke, into yokugcina ofuna ukwenzeka ukuthi ihluleke uma idingeka ukuze usebenze kahle.

Izixhumi ziyakwazi ukumelana nokufakwa nokususwa, ukudlidliza, noma ukuya kweminye imisebenzi, kuyilapho ukuxhumeka kwengxenye okuqhubekayo, ukunqanyulwa kwemvelo ukuze kuqinisekiswe ukuthi ukuqina kokuxhumeka, ukuze kuzuzwe ukwethembeka komshini.

Kusukela emazingeni okushisa adlulele kanye namazinga omswakamo kuya ekuvikelweni kothuli noketshezi, i-IP (I-Ingress Protection) nezinye izilinganiso zemvelo mayelana namandla okuvikela isixhumi ezimweni zangaphandle ziyahlolwa ukuze kuqinisekiswe ukuthi ikhono lokukwazi ukusebenza endaweni eyingozi kakhulu lingaba elivamile futhi. engathinteki.

Ukuqinisekisa ukuxhumana okuthembekile ngokuhamba kwesikhathi, kubalulekile ukushaya ibhalansi enhle phakathi kokuqina nokusebenza kahle. Ukufakwa kwegolide endaweni okuthintana kuyo kuvimbela ukufakwa kwe-oxidation. Ingxubevange yethusi esetshenziselwa umzimba kanye nokuxhumana ibhalansisa amandla kanye nokusebenza, okunikela ekusebenzeni kahle kwesixhumi.

Uzibona kanjani (khetha) izixhumi ze-PCB?

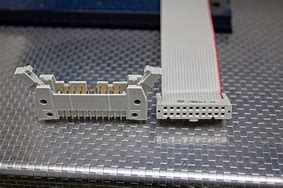

Ukuze ubone noma ukhethe izixhumi ze-PCB, qala ubheke umumo wesixhumi, usayizi, inani lamaphini, nokuhlelwa kwezici.

Lokhu kuzosiza ukunquma uhlobo lwesixhumi. Okwesibili, cabangela uhlobo lwephinikhodi yesixhumi (isb. izikhonkwane, amasokhethi, amaphedi, njll.) nokuhlelwa, kanye nohlobo lwesixhumi esibonakalayo (njengohlobo lwe-D, i-USB, i-HDMI, njll.). Ekugcineni, hlola ilogo nenombolo kusixhumi se-PCB ukuze unqume uhlobo lwayo.

Cacisa izidingo zohlelo lokusebenza lwesixhumi. Cabangela okokusebenza kwe-elekthronikhi, amasistimu, noma izinhlelo zokusebenza ezizosebenzisa isixhumi, kanye nesimanje, i-voltage, nohlobo lwesignali isixhumi okudingeka siluphathe.

Cabangela izithiyo zesikhala sebhodi kanye nezidingo zesakhiwo. Khetha usayizi wesixhumi esifanele, umumo, kanye nenombolo yezikhonkwane ngokusekelwe kusayizi webhodi, isakhiwo, nesikhala phakathi kwezingxenye. Qinisekisa ukuthi isixhumi singashintshwa ngokuvumelana nezidingo zokuklama zebhodi.

Ukuthembeka nokuqina kwesixhumi kubalulekile ekusebenzeni okuzinzile kwesikhathi eside. Izixhumi ezinekhwalithi enhle yezinto ezibonakalayo nezinqubo zokukhiqiza ezingamelana nokushintsha kwezinga lokushisa, ukudlidliza, ukushaqeka, namakhemikhali kufanele kukhethwe.

Amapharamitha afana nempilo yepulaki kanye nokumelana nokuxhumana kwesixhumi kufanele kucatshangelwe. Ukwengeza, kubalulekile ukucabangela izimo zemvelo lapho isixhumi sizovezwa khona. Khetha izixhumi ezinezinto ezifanele ezingangeni manzi, ezingangenwa uthuli, futhi zimelana nokugqwala ngokusekelwe ezimweni zemvelo, njengezinga lokushisa, umswakama, nokuchayeka ezintweni ezigqwalisayo nothuli.

Cabangela izidingo zokufakwa nokunakekelwa kwesixhumi, bese ukhetha izixhumi okulula ukuzifaka, ukuzixhuma, nokuzinakekela ukuze kuncishiswe isikhathi nezindleko zenqubo yokukhiqiza nokulungisa.

Cabangela izidingo zokufakwa nokunakekelwa kwesixhumi, bese ukhetha izixhumi okulula ukuzifaka, ukuzixhuma, nokuzinakekela ukuze kuncishiswe isikhathi nezindleko zenqubo yokukhiqiza nokulungisa. Qinisekisa ukusebenza kahle kwezindleko ngokukhetha izixhumi ezihlangabezana nezidingo ngaphandle kokweqa isabelomali.

Ungawaxhuma kanjani amabhodi e-PCB?

I-soldering iyindlela evamile yokuxhuma amabhodi e-PCB. Kuhilela ukusebenzisa amathuluzi e-solder nawokuhlanganisa ukuze kuxhunywe izikhonkwane zengxenye ye-elekthronikhi kumaphedi ebhodini le-PCB. Lokhu kunikeza uxhumano lukagesi oluthembekile namandla emishini kumishini eminingi kagesi.

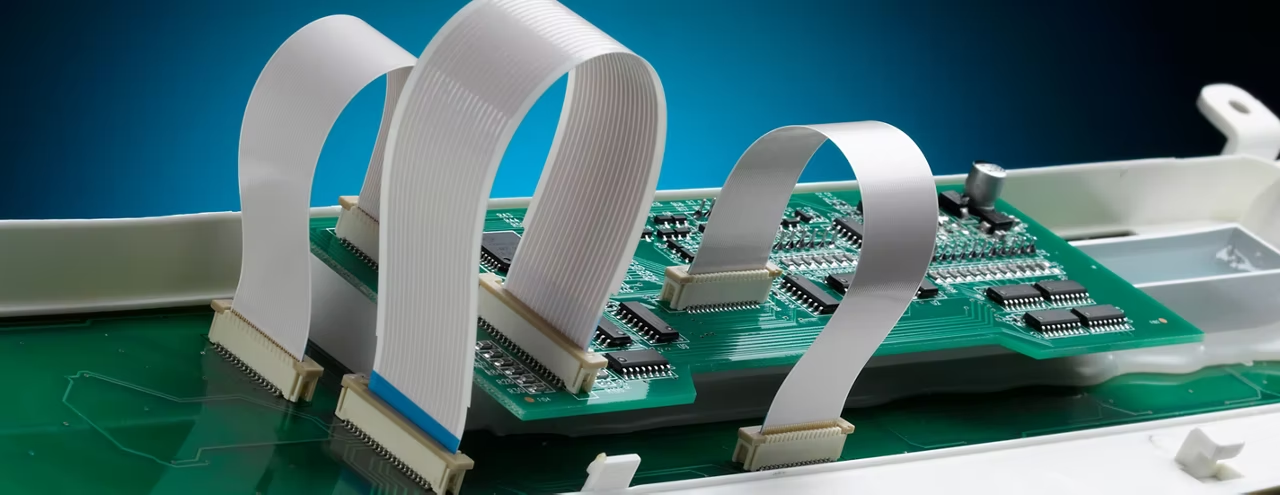

Izixhumi zokuxhuma, ngakolunye uhlangothi, zishuthekwa ezindaweni zokuxhuma ebhodini le-PCB kusetshenziswa izikhonkwane noma amasokhethi. Le ndlela ivumela ukuxhuma okusheshayo nokukhipha ibhodi kwamanye amamojula noma amadivaysi, okwenza ifaneleke izinhlelo zokusebenza ezidinga ukushintshwa noma ukulungiswa njalo.

Izixhumi zothintana naye zasentwasahlobo, ezisebenzisa othintana nabo basentwasahlobo ukuze baxhume kumaphedi noma izikhala ku-PCB, ngokuvamile zisetshenziswa ezinhlelweni ezidinga ukudluliswa kwedatha ngesivinini esiphezulu noma ukuxhuma njalo nokukhipha amapulaki, okufana nempahla yokuxhumana enesivinini esiphezulu noma okokusebenza kokuhlola.

Amabhulokhi wetheminali ye-PCB: Amabhulokhi wetheminali ye-PCB ayizixhumi ezisetshenziselwa ukunamathisela izintambo noma okuholela ebhodini lesekethe le-PCB. Zivikelwa ngokukrunjwa noma ngokuklwebhana ukuze kuqinisekiswe ukuxhumana okuthembekile kukagesi.

Ikusasa Lezixhumi ze-PCB: Ukuqamba Nokuthuthuka:

Ukuthuthukiswa kwezixhumi ze-PCB kuzogxila ekusungulweni nasekuthuthukiseni usayizi omncane, ukuminyana okuphezulu, ukudluliswa kwesivinini esikhulu, ukwethembeka, ukuzenzekelayo, ukuvikelwa kwemvelo, kanye nokuxhumana okungenantambo. Lezi zinto ezintsha zizothuthukisa ukusebenza nokusebenza kwemishini kagesi ukuze kuhlangatshezwane nesidingo esikhulayo semakethe.

Umgomo uwukuthola usayizi omncane kanye nokuminyana okuphezulu. Imishini kagesi iba mincane futhi iba lula, futhi ngenxa yalokho, izixhumi ze-PCB nazo ziba zincane futhi ziminyene kakhulu. I-Miniature, high-density, nezixhumi zebhodi lesifunda ezivumelana nezimo manje sezivame ukusetshenziswa emikhiqizweni emincane efana nomakhalekhukhwini, ama-tablet PC, namadivayisi agqokekayo.

Lezi zixhumi zilungele ukudluliswa kwesivinini esikhulu kanye nezinhlelo zokusebenza ze-high-frequency. Ngenxa yesidingo esikhulayo sokuxhumana nokudluliswa kwedatha, izixhumi ze-PCB kufanele zisekele amazinga aphezulu okudluliswa kwedatha namaza. Izixhumi zesiginali ezihlukanisayo ezinesivinini esikhulu, njenge-USB Type-C neThunderbolt, kanye nezixhumi ze-RF njengezixhumi ze-antenna, zivame ukusetshenziswa.

Izixhumi ze-PCB zidinga ukwethembeka okuphezulu nokuqina ukuze zimelane nezimo zokusebenza eziyinkimbinkimbi kanye nokuxhumeka okuvamile nokunqanyulwa. Lokhu kungafezwa ngokusebenzisa izinto ezengeziwe ezingagugi, ukuqinisa ukwakheka kwezindawo zokuxhumana, nokusebenzisa ubuchwepheshe bokuxhumana obuthembeke kakhulu.

Ukwengeza, i-automation kanye ne-intelligence ingasetshenziswa. Imboni yokukhiqiza ibona ukwenyuka kokuzenzakalelayo nobuhlakani, futhi izixhumi ze-PCB zilandela okufanayo. Manje sezihlonyiswe ngezindlela zokufaka nokususa ezizenzakalelayo, imisebenzi yokuhlonza nokulungisa, ukudluliswa kwedatha, namandla okuxhumana.

Kukhona ukugcizelela okukhulayo ekuvikelweni kwemvelo kanye nokusimama. Ukwenziwa nokusetshenziswa kwezixhumi ze-PCB kuya ngokuya kugxila ebunganeni bemvelo ngenxa yenkambiso yokuvikela imvelo nokusimama. Lokhu kufaka phakathi ukusetshenziswa kwezinto ezingaphinda zisetshenziswe, izinqubo zokukhiqiza amandla amancane, kanye nedizayini yesixhumi esikhiphekayo.

Isikhathi sokuthumela: Mar-21-2024